Build guide

Welcome to the build guide! Before you assemble, make sure you grab everything you need– tools, printed parts and ordered parts. All hardware is M3 unless otherwise stated.

-

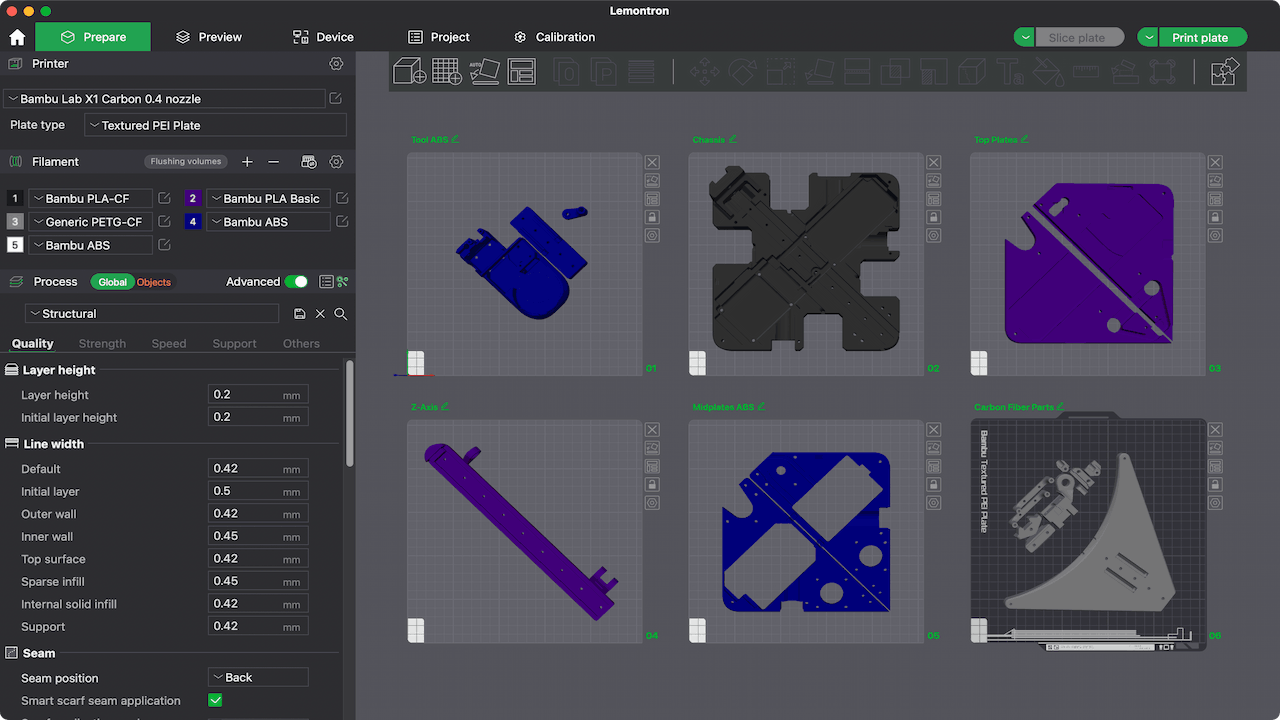

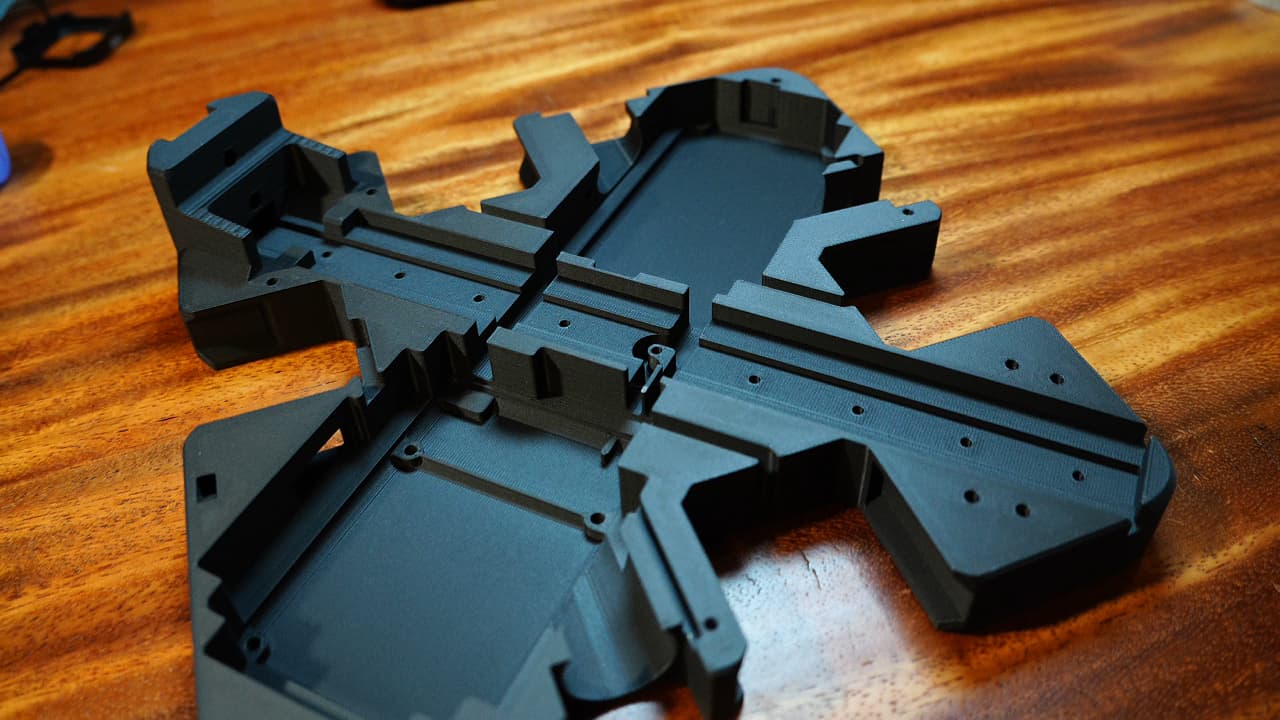

Print the parts

Check out the Printed Parts page for important information.

Check out the Printed Parts page for important information. -

Install the software

Use the Software Guide to install the required software on to the Raspberry Pi and SKR Pico. The SKR Pico is hard to reach once the Lemontron is assembled!

Use the Software Guide to install the required software on to the Raspberry Pi and SKR Pico. The SKR Pico is hard to reach once the Lemontron is assembled! -

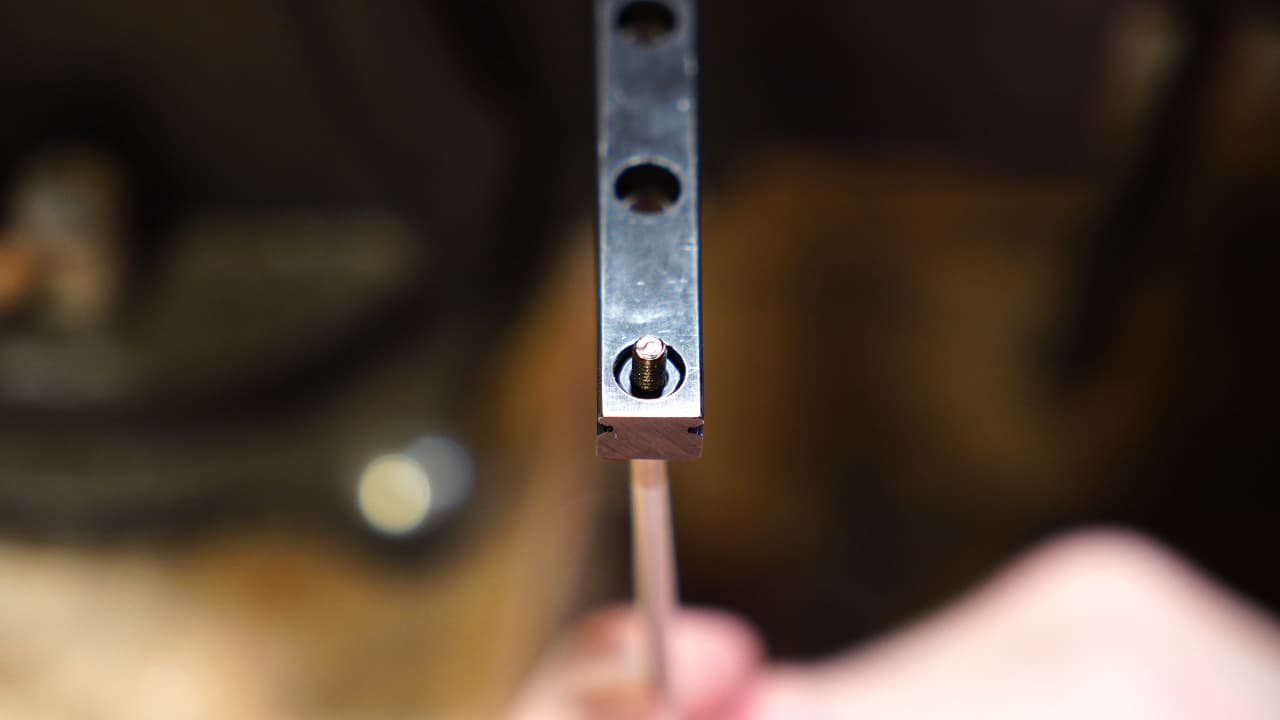

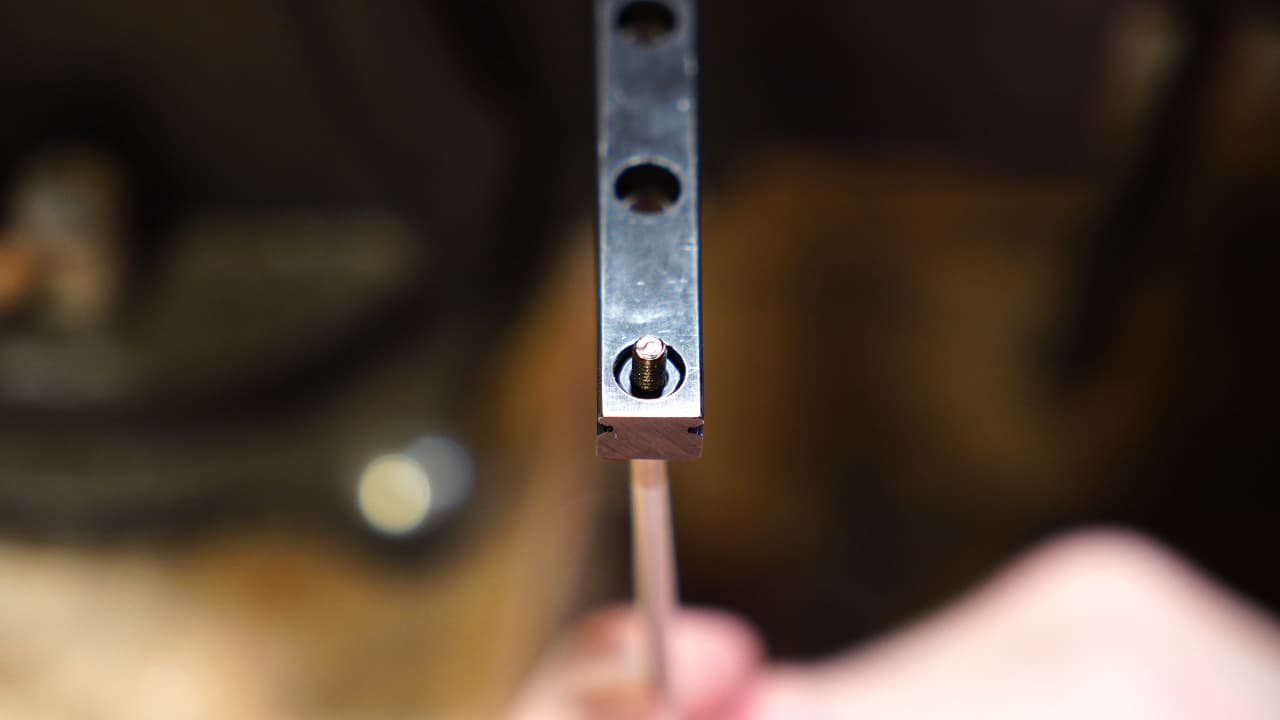

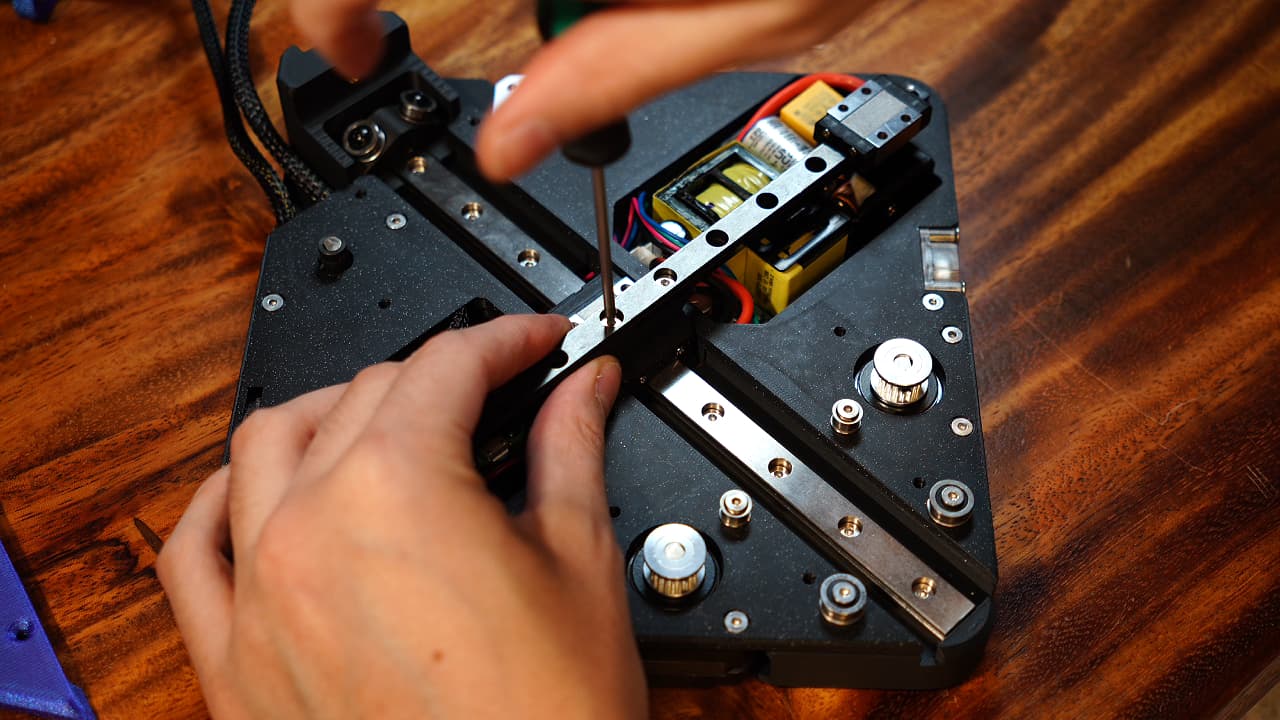

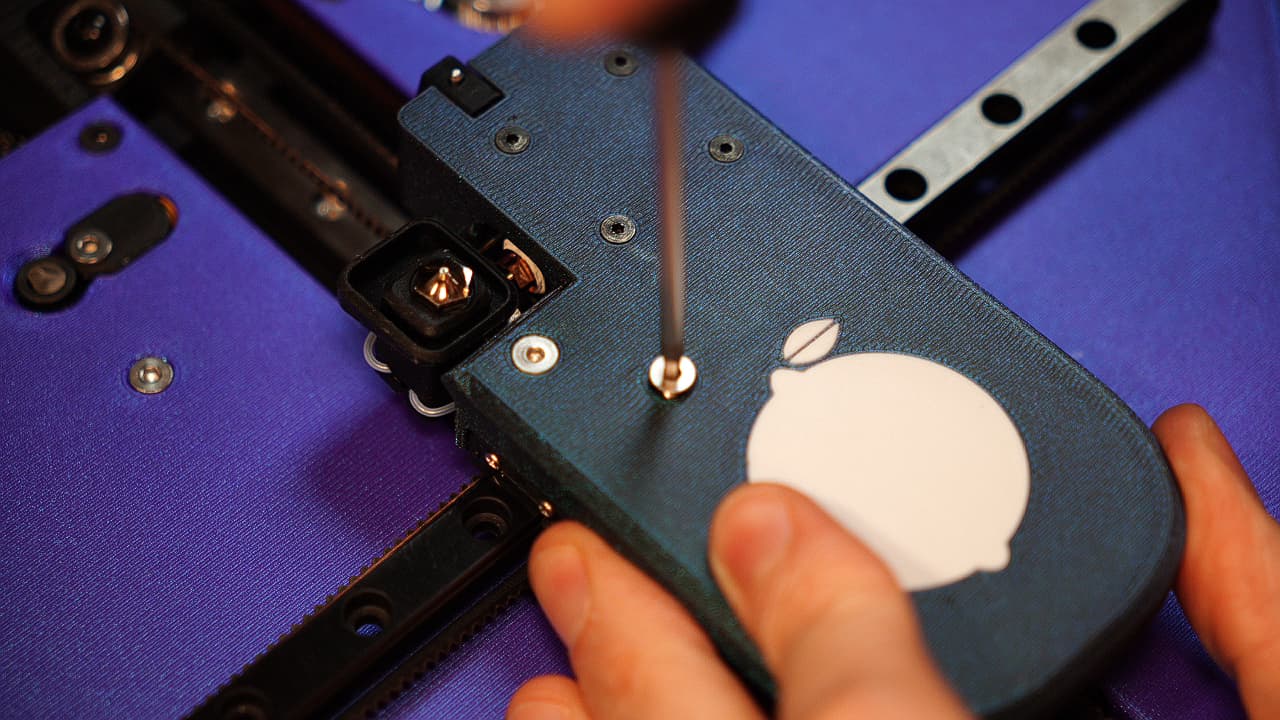

Insert the screws

Drop two screws into the holes.M340mm

Drop two screws into the holes.M340mm -

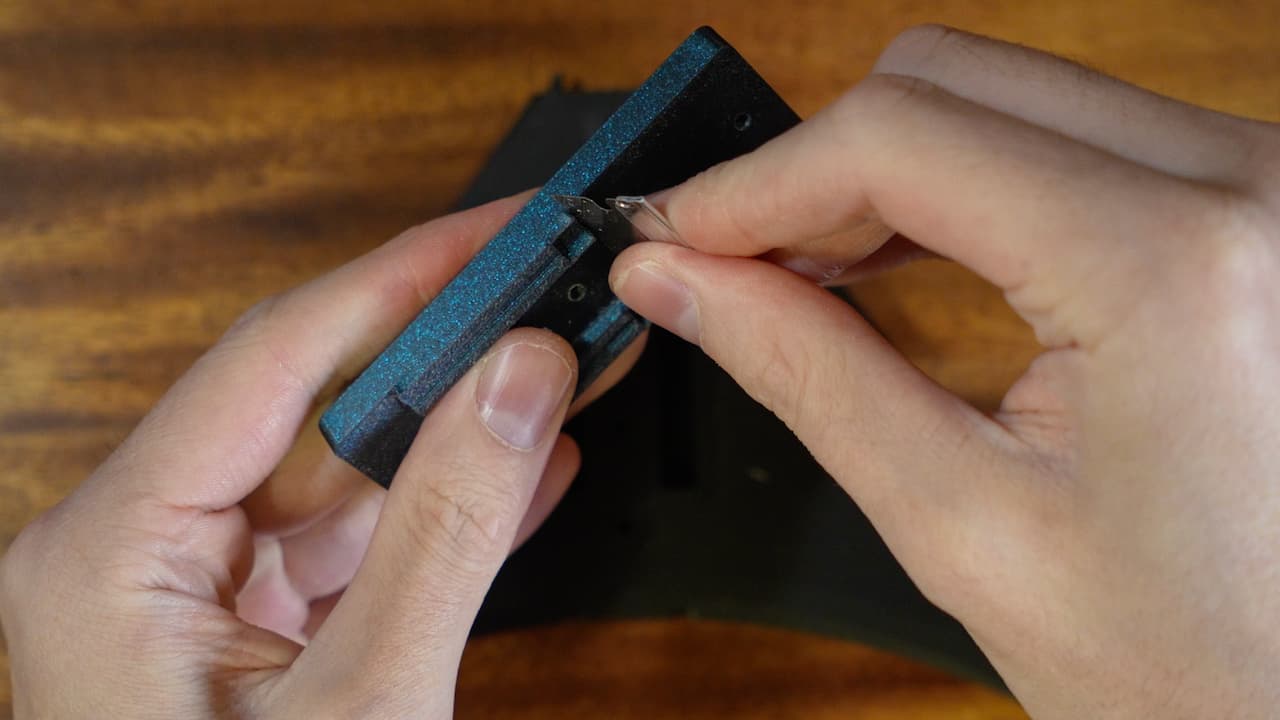

Scrape the mating surface flat

Using a blade, lightly scrape the surface. This will remove any gaps and make the parts fit together beautifully.

Using a blade, lightly scrape the surface. This will remove any gaps and make the parts fit together beautifully. -

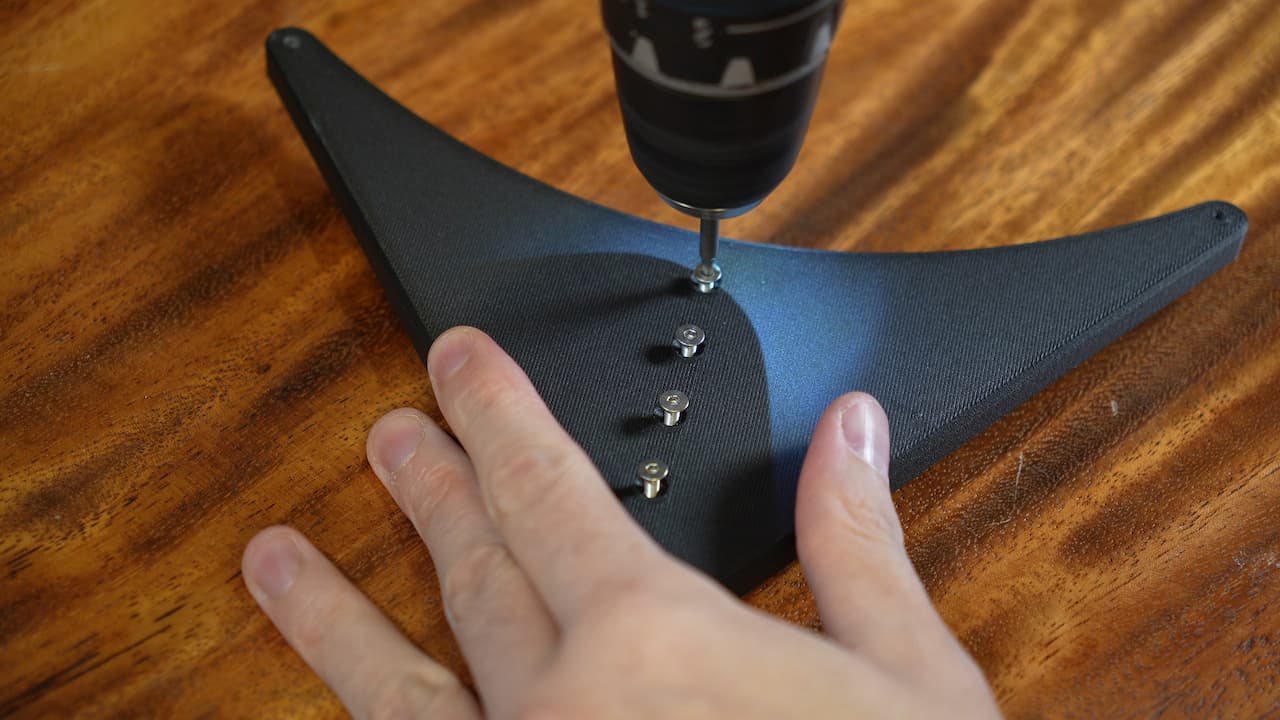

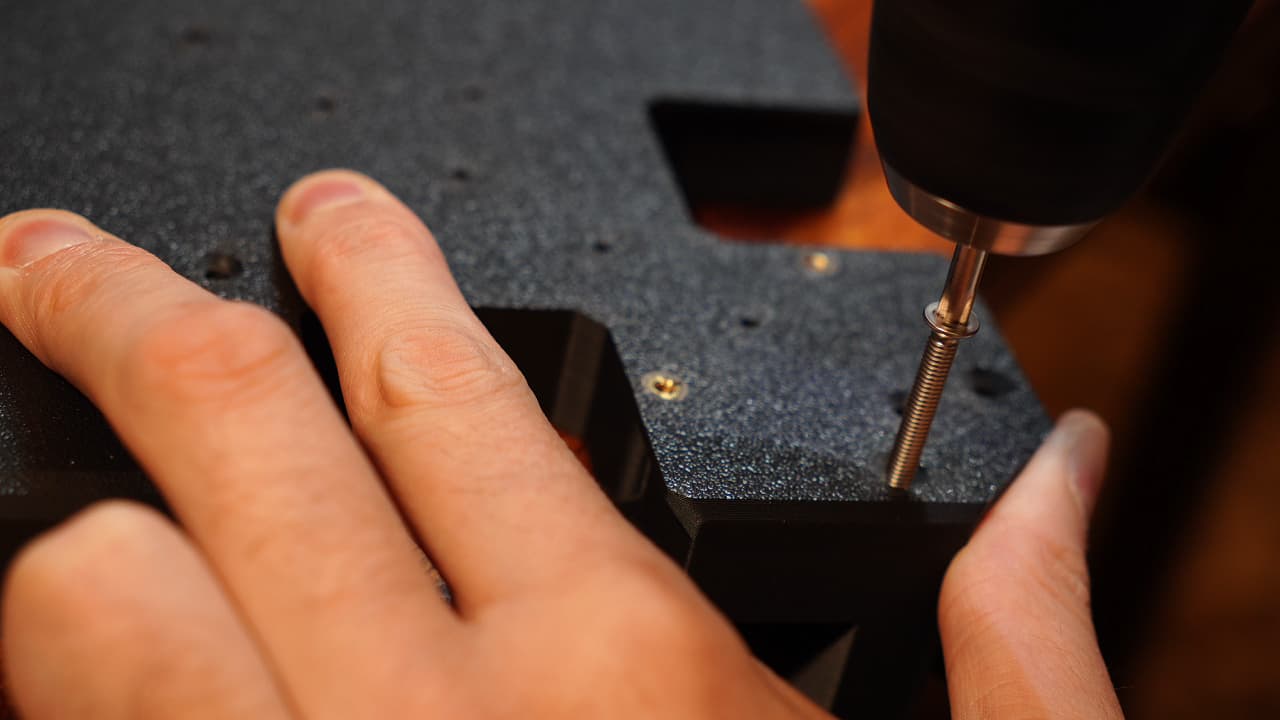

Screw in the spine

Secure it with 5 screws.M314mm

Secure it with 5 screws.M314mm -

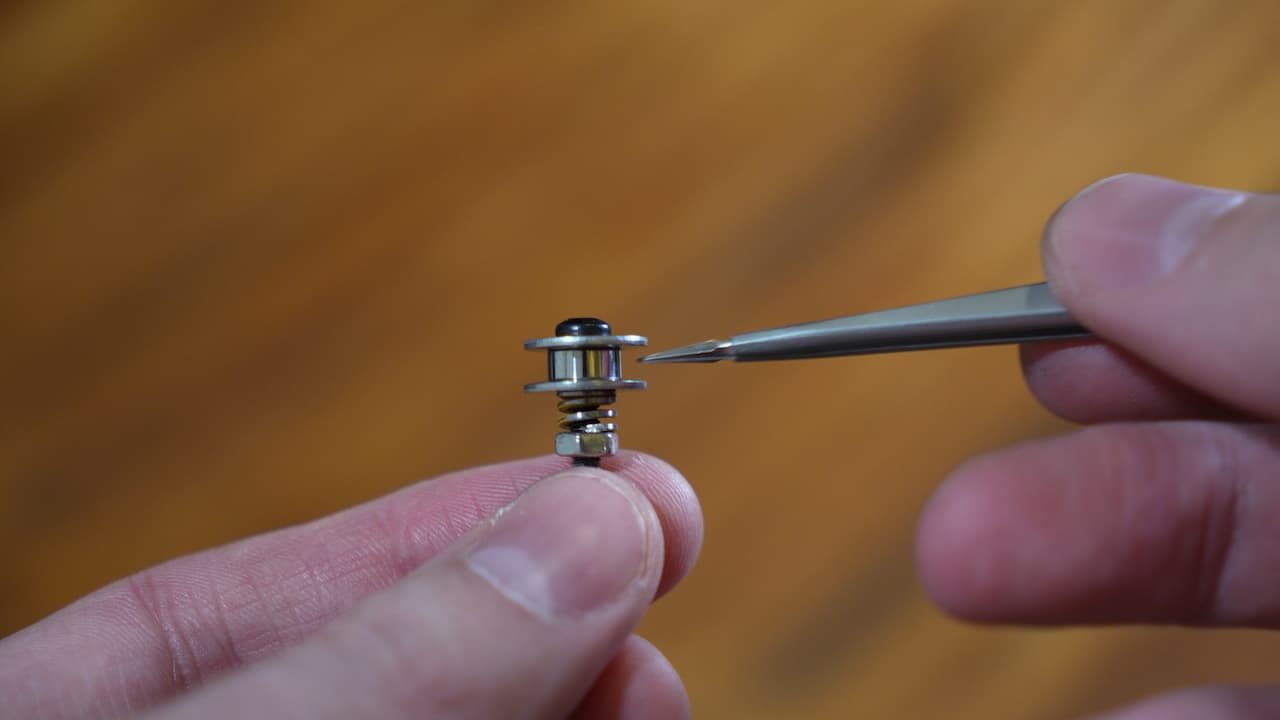

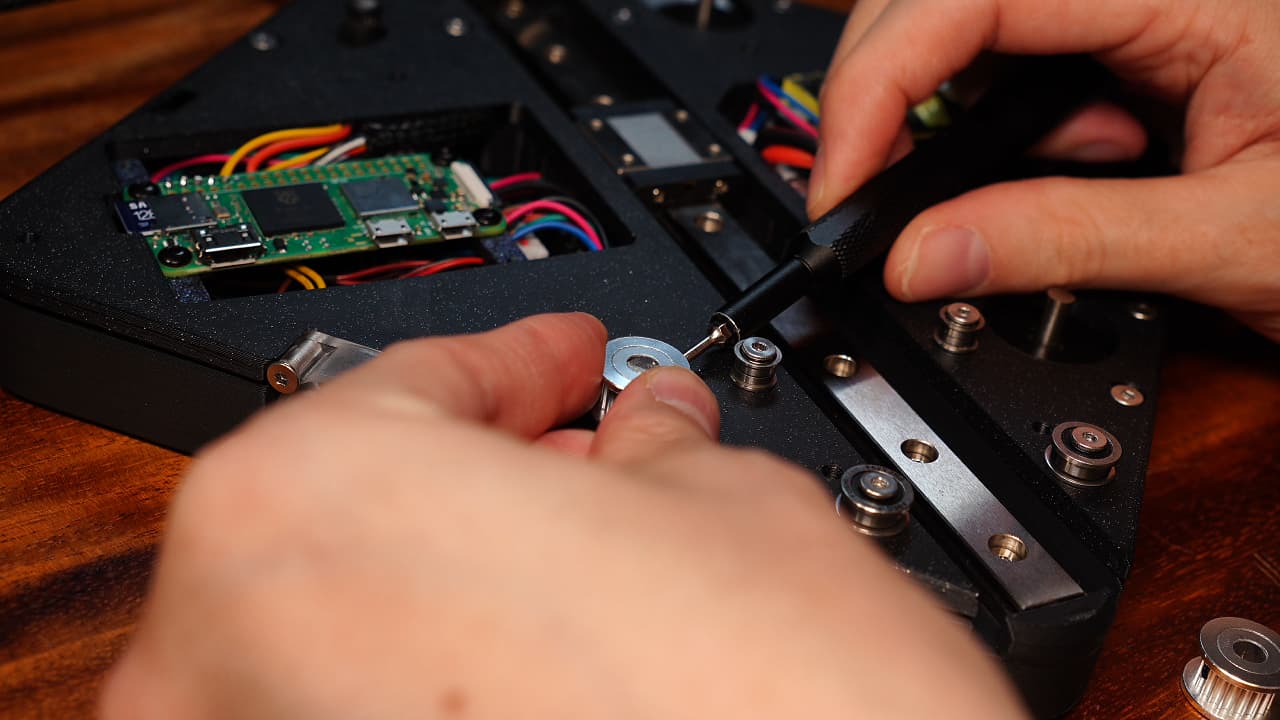

Install the posts

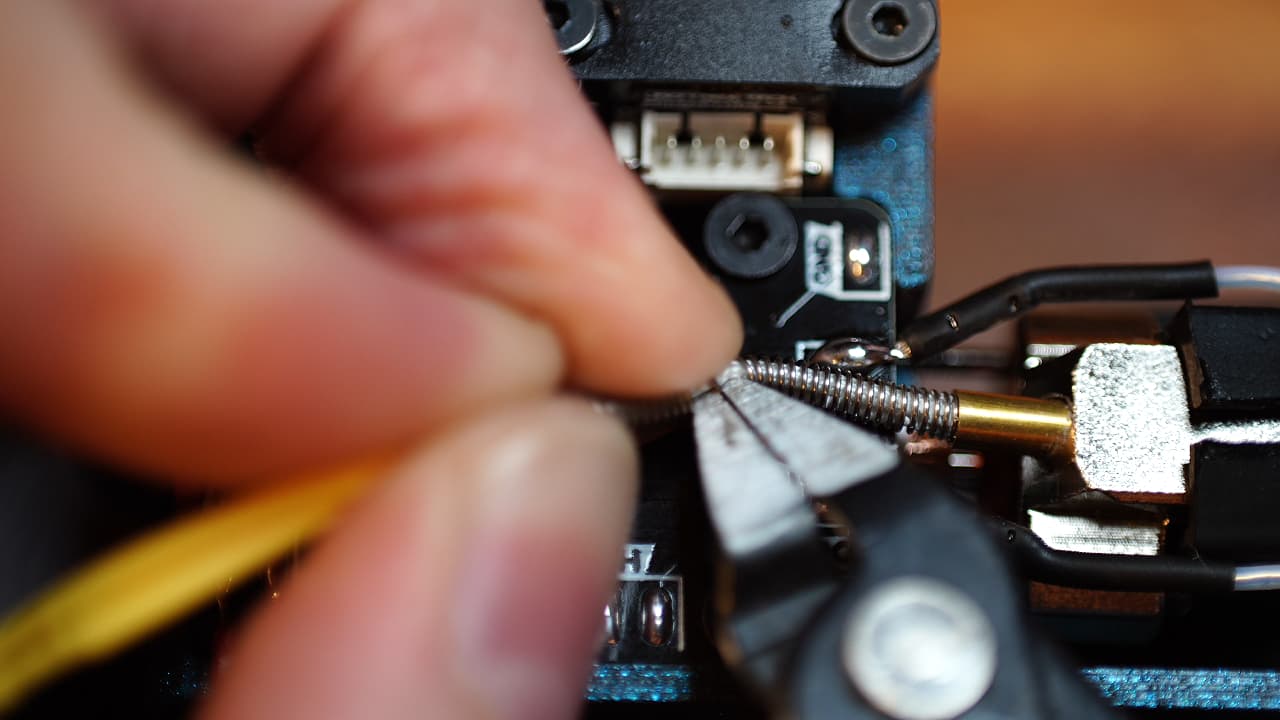

Onto the screws, drop a 12mm washer, small bearing, another washer, a yellow spring that's been cut in half, and a nut.M320mm

Onto the screws, drop a 12mm washer, small bearing, another washer, a yellow spring that's been cut in half, and a nut.M320mm -

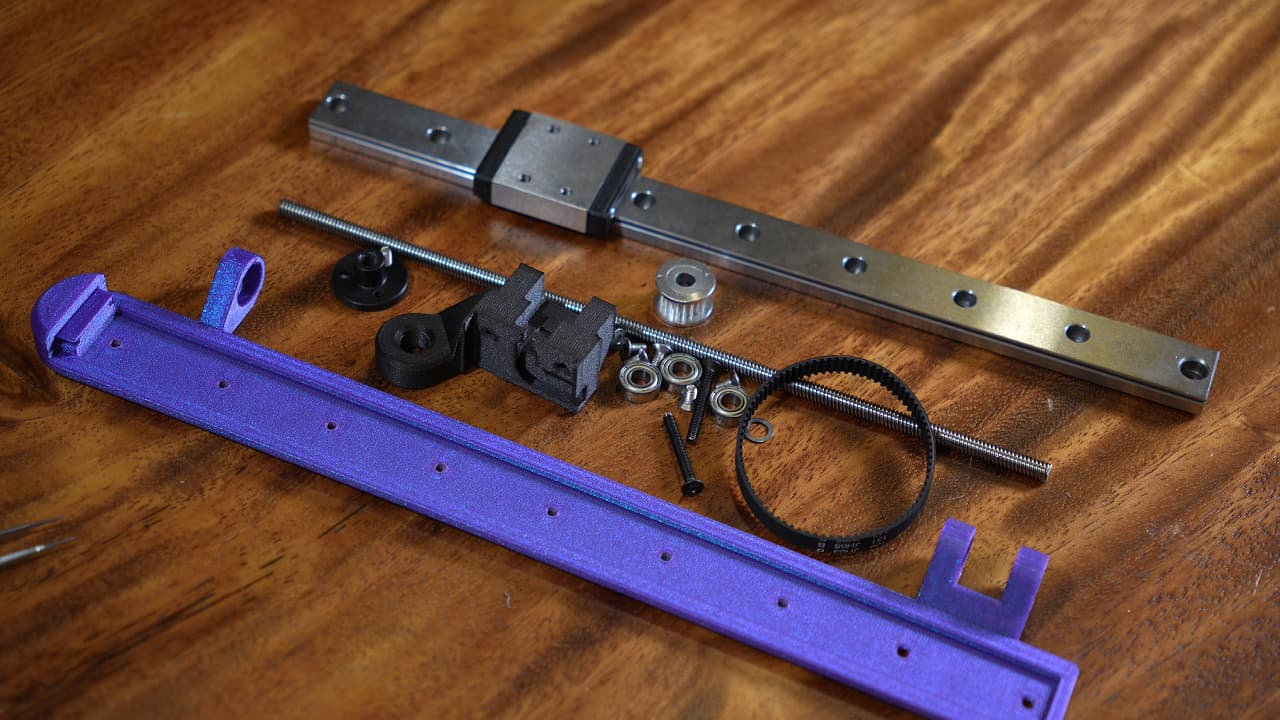

Gather Z-Axis parts

Gather the Z axis (printed), bracket (printed), MGW9C linear rail, 6 × 3d-printed spacers, 6 × 8mm countersunk screws, 2 × 25mm wafer head screws, M5 shims, M5 bearings, lead screw & nut, drive pulley and belt.

Gather the Z axis (printed), bracket (printed), MGW9C linear rail, 6 × 3d-printed spacers, 6 × 8mm countersunk screws, 2 × 25mm wafer head screws, M5 shims, M5 bearings, lead screw & nut, drive pulley and belt. -

Insert the bearings

Insert 3 MR115 bearings into the seats.Or, you can actually omit the top bearing if you want.

Insert 3 MR115 bearings into the seats.Or, you can actually omit the top bearing if you want. -

Insert the lead screw

Insert the lead screw through so that it just pokes through the bottom bearing.

Insert the lead screw through so that it just pokes through the bottom bearing. -

Drop in the first shim

Drop in the first shim. This shim allows the bearing to turn while pressing against the drive pulley.

Drop in the first shim. This shim allows the bearing to turn while pressing against the drive pulley. -

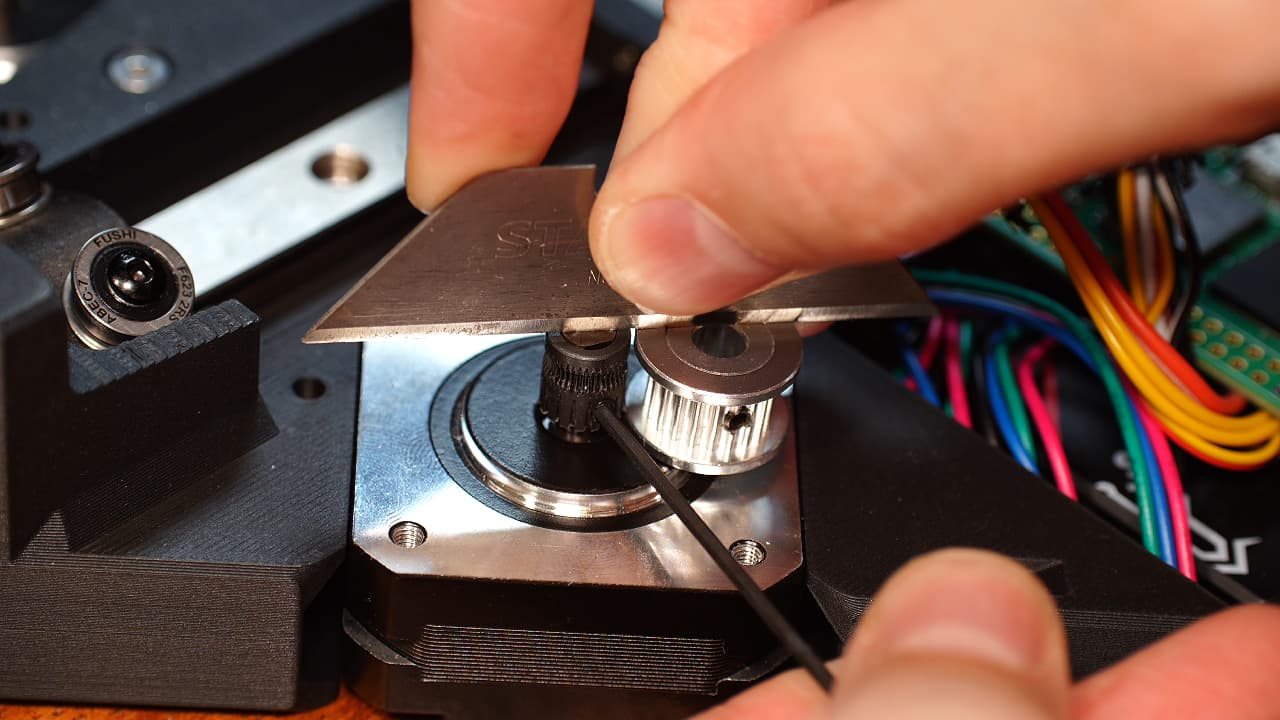

Drop in the drive pulley

Drop in the drive pulley with the belt pre-installed. Advance the lead screw flush with the top of the pulley.

Drop in the drive pulley with the belt pre-installed. Advance the lead screw flush with the top of the pulley. -

Fish in the second shim

Use something thin to fish in the second shim. Push the lead screw all the way through.

Use something thin to fish in the second shim. Push the lead screw all the way through. -

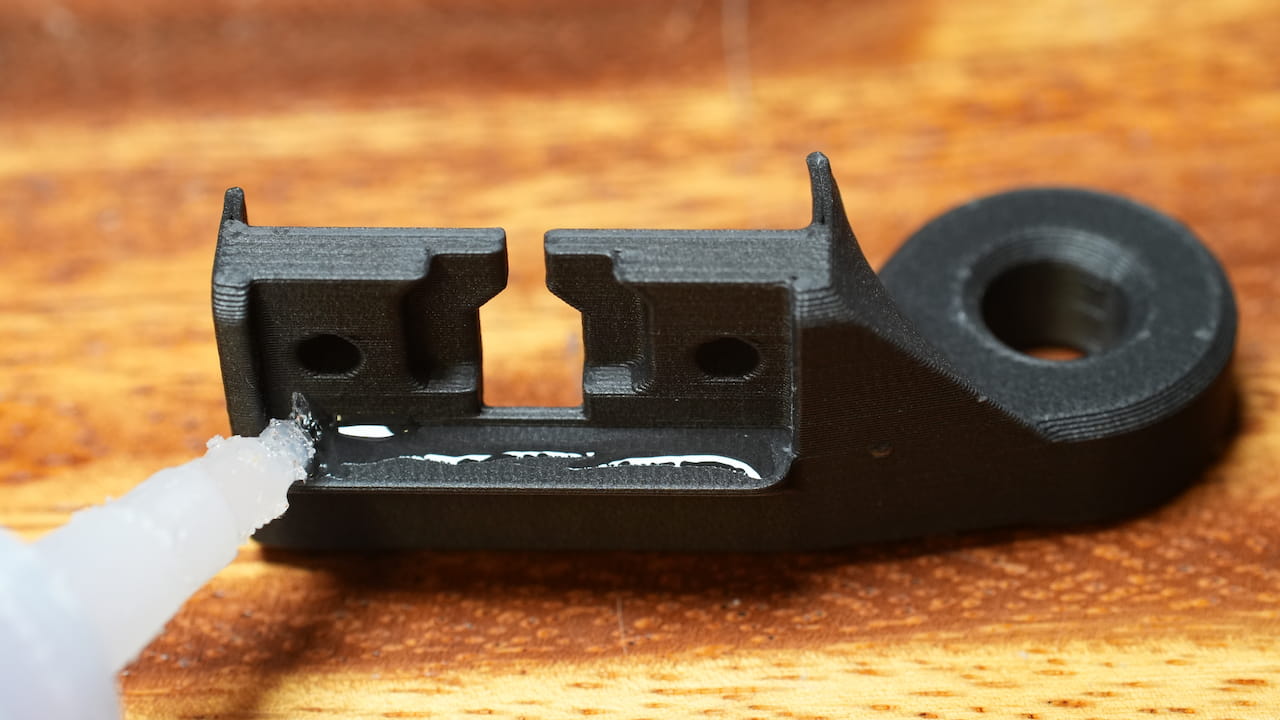

Glue the bracket

Dap some supa glue on the ledge on the bracket.

Dap some supa glue on the ledge on the bracket. -

Press & dry the glue

Press the top of the bracket onto a flat surface while it dries.

Press the top of the bracket onto a flat surface while it dries. -

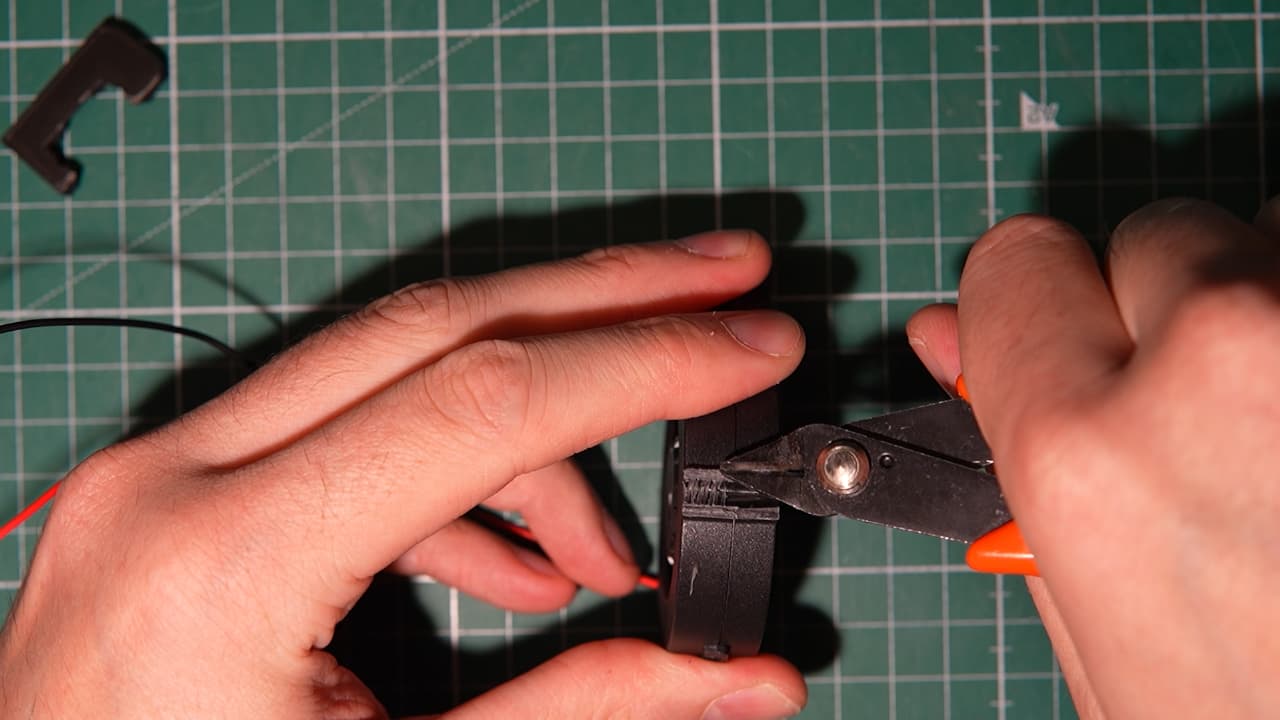

Clip off the support

Clip off the support from the bottom with flush cutters.

Clip off the support from the bottom with flush cutters. -

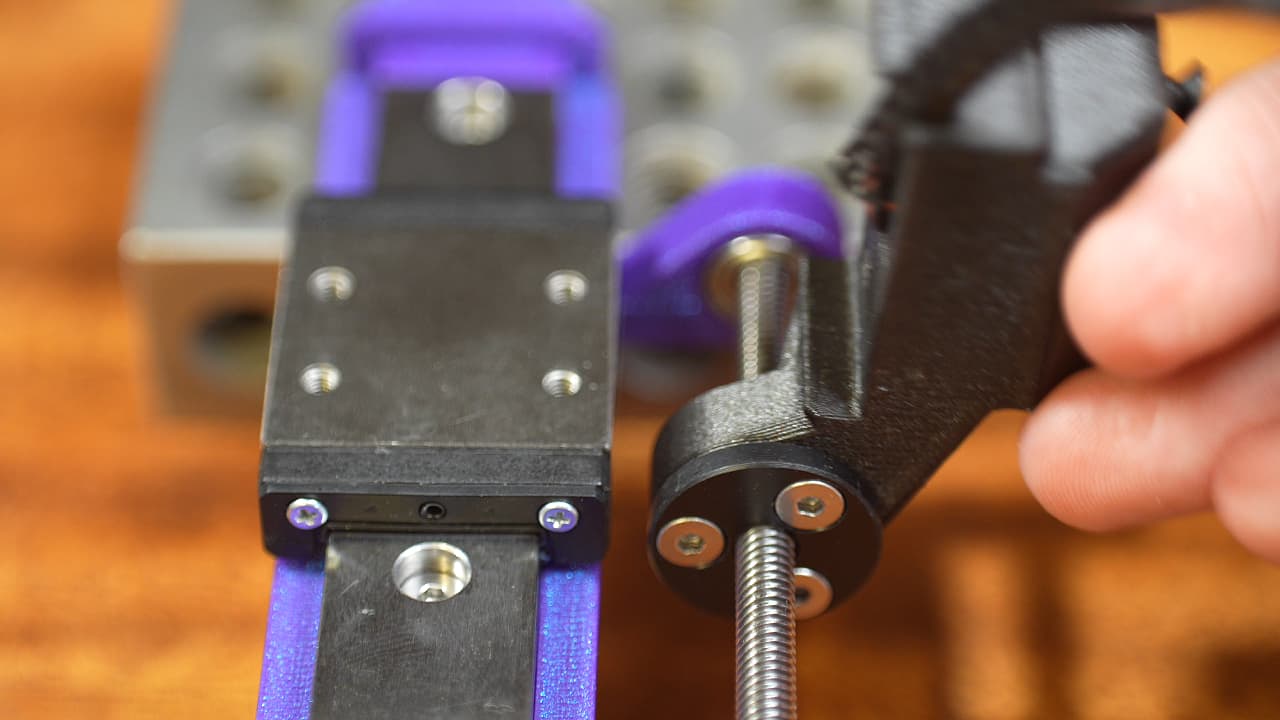

Insert the lead nut

Insert the nut that came with the lead screw to the bracket.

Insert the nut that came with the lead screw to the bracket. -

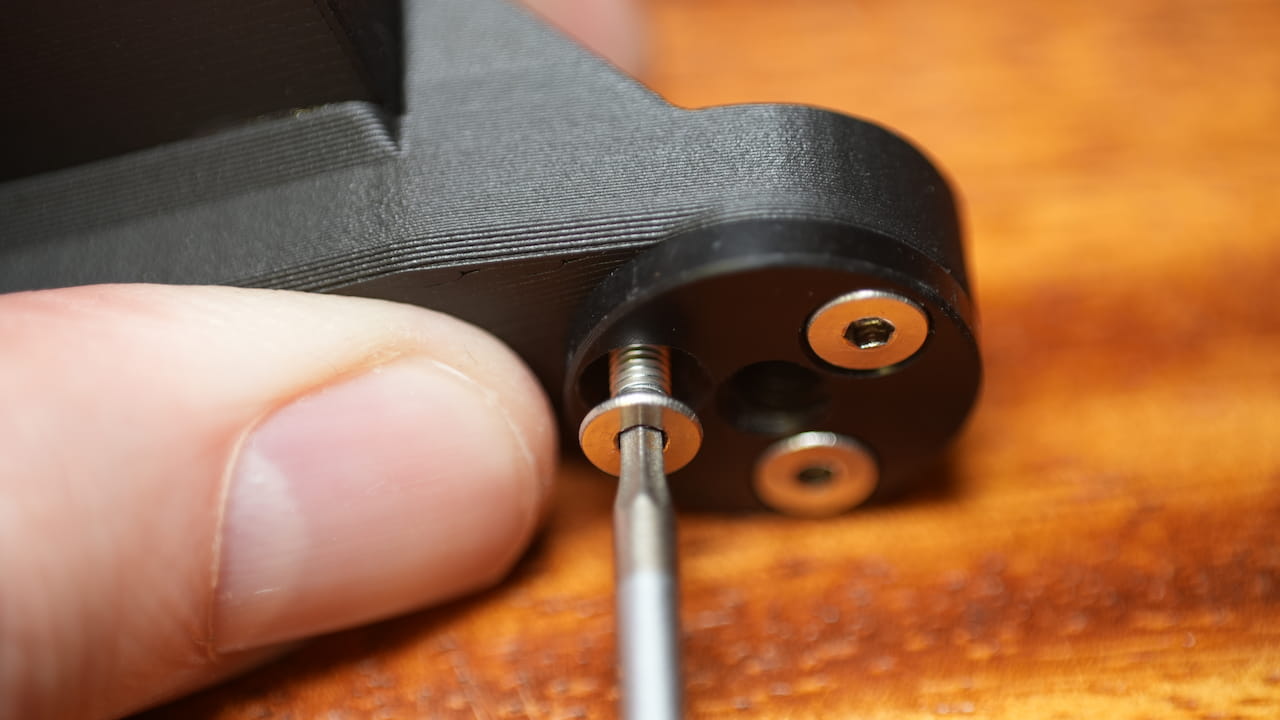

Attach the lead nut

Attach the lead nut to the bracket.M38mmIf your nut isn't countersunk, countersink it.

Attach the lead nut to the bracket.M38mmIf your nut isn't countersunk, countersink it. -

Add the bracket

Install the bracket onto the lead screw.

Install the bracket onto the lead screw. -

Cut the lead screw

Align the lead screw's top with the top of the bearing seat and CUT the bottom off.

Align the lead screw's top with the top of the bearing seat and CUT the bottom off. -

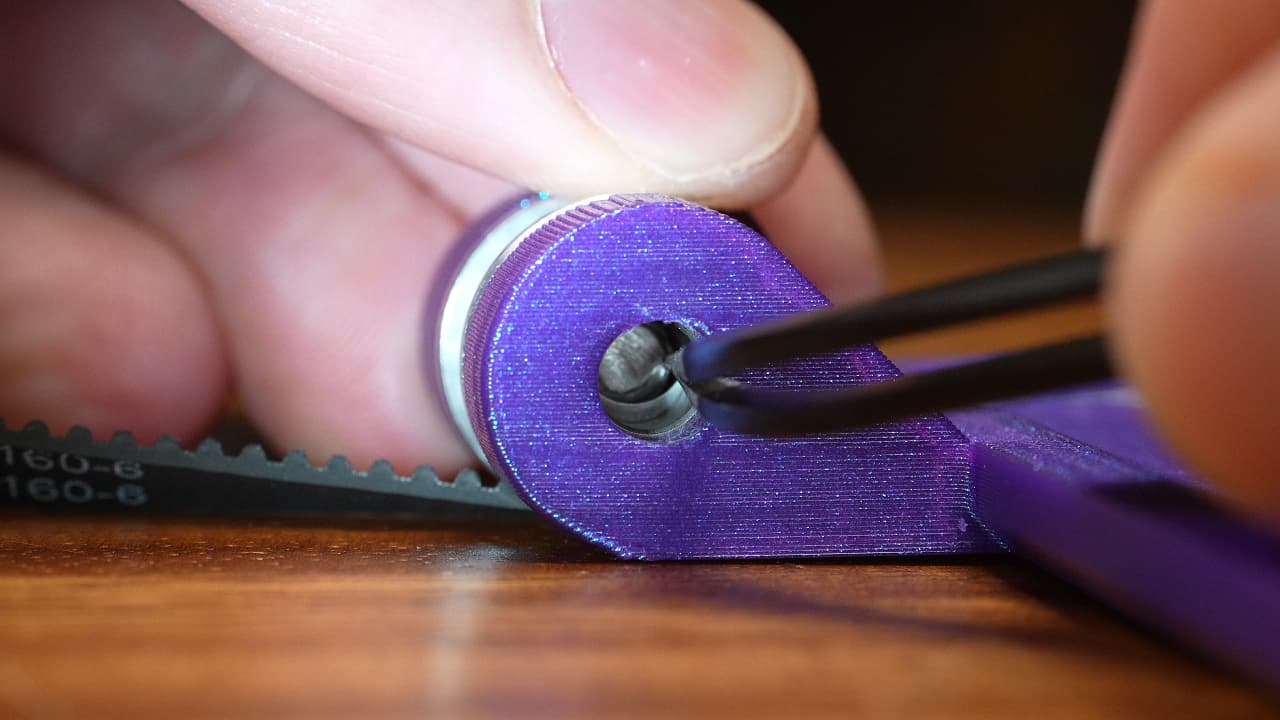

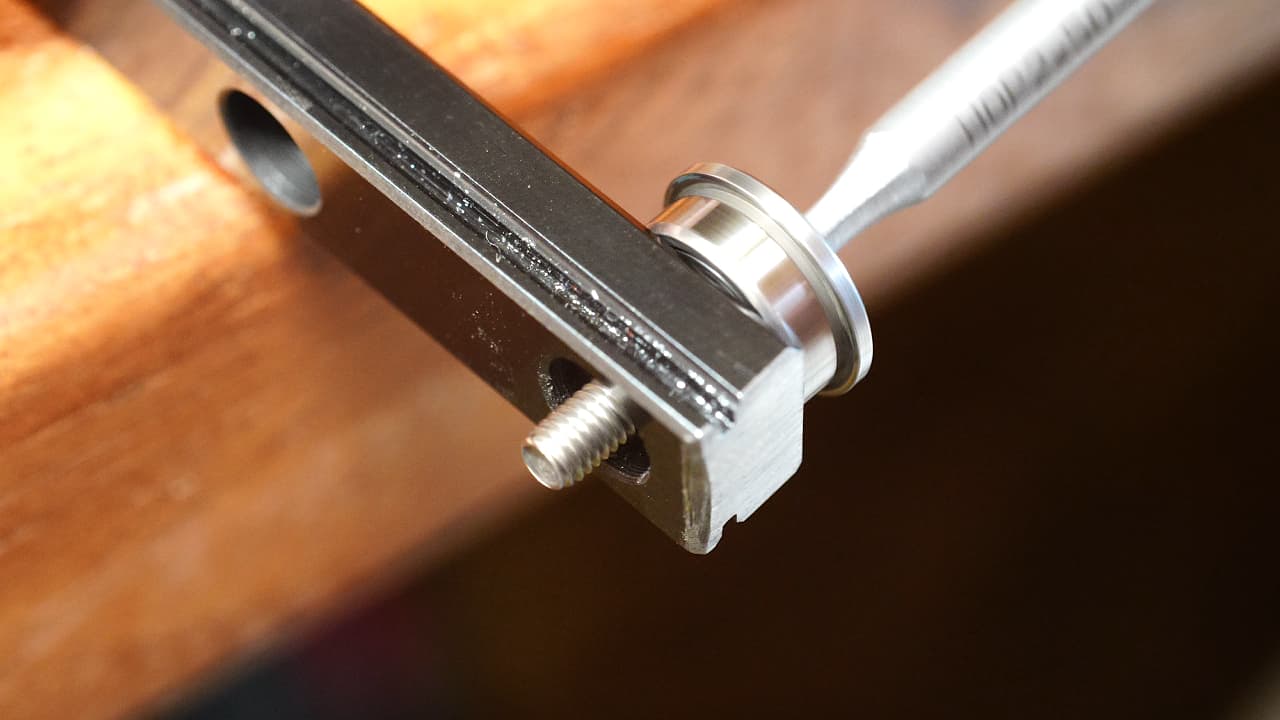

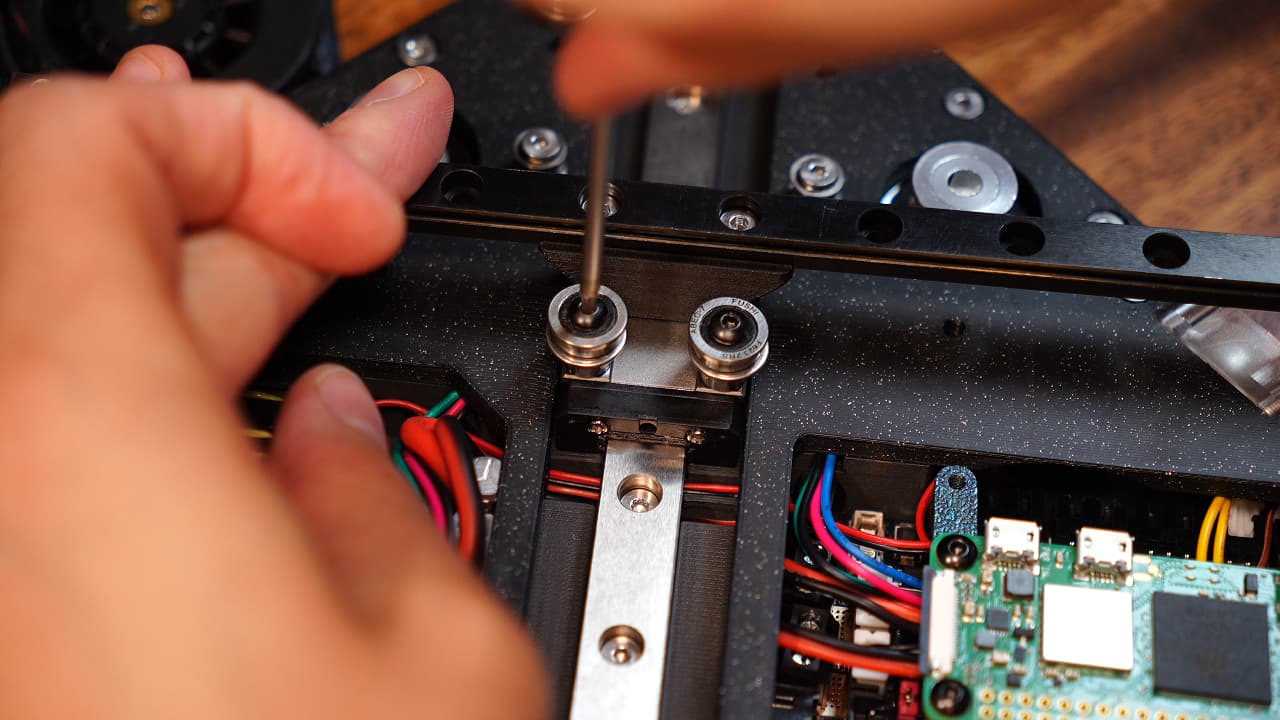

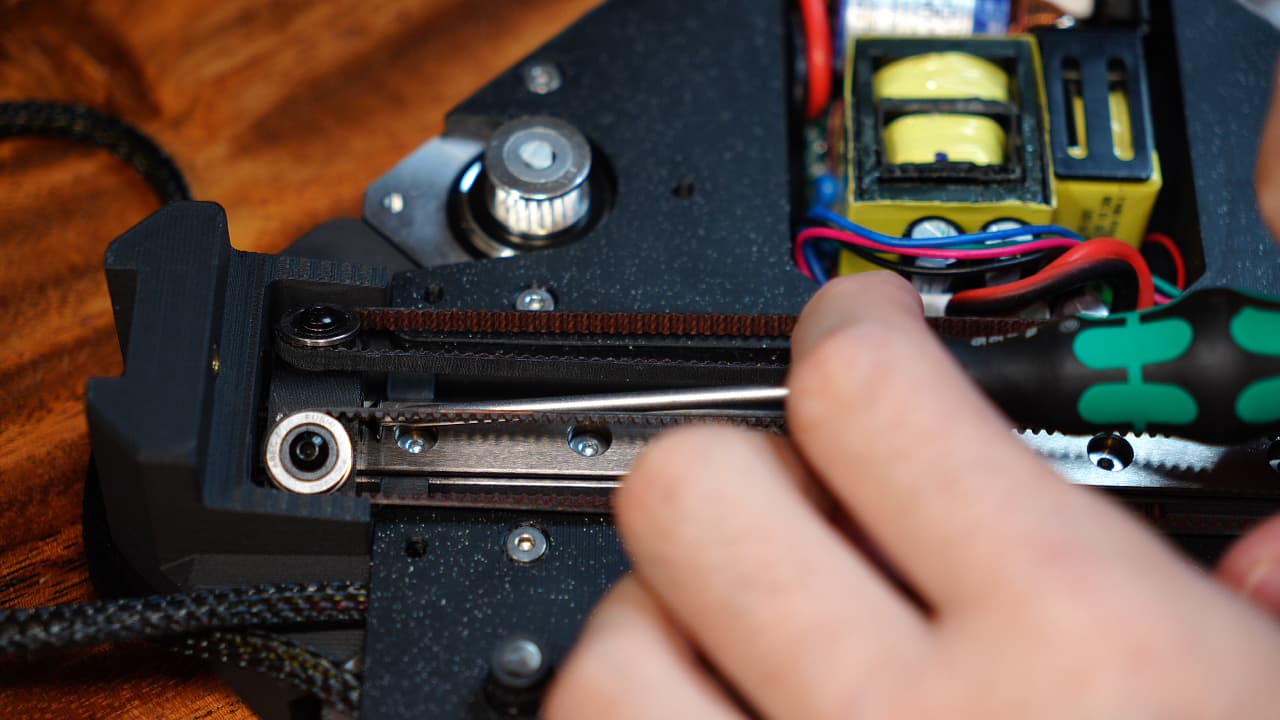

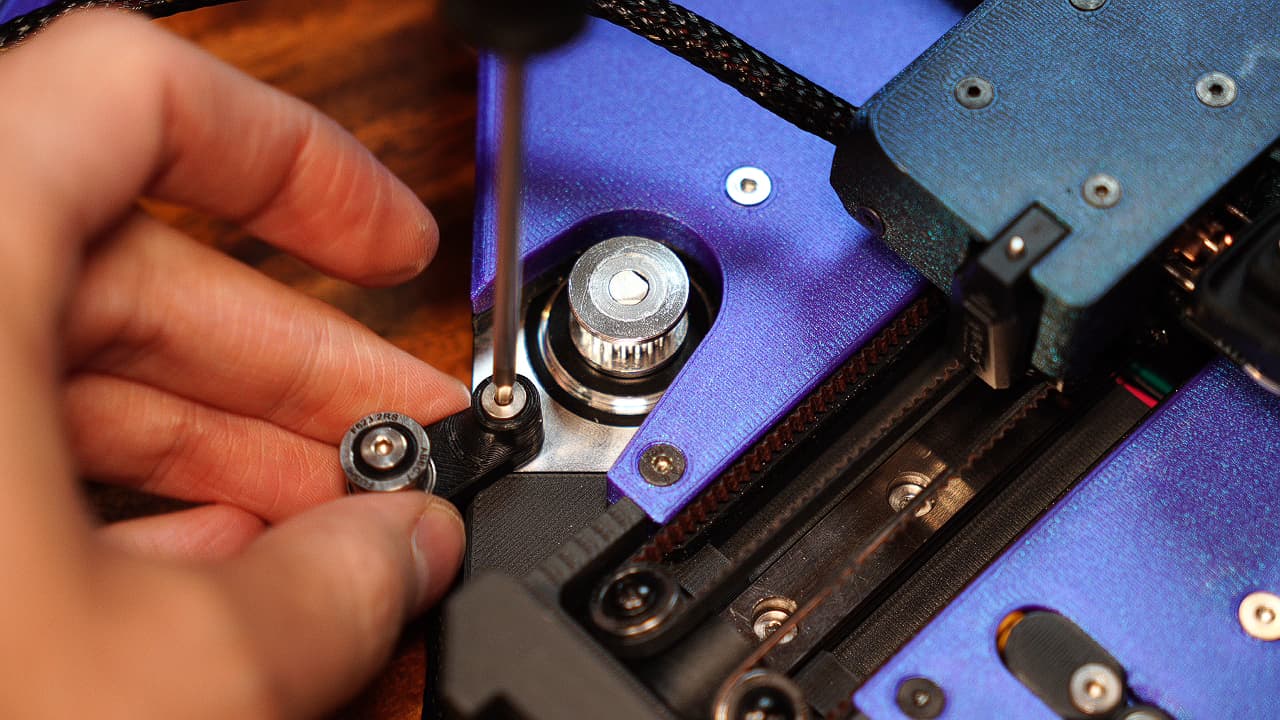

Tighten grub screws

Tighten the grub screws using a 1.5mm allen key.

Tighten the grub screws using a 1.5mm allen key. -

Install the rail & spacers

Lay down the rail, then starting at the top hole, add 3d printed spacers to the first 3 holes, omit the 4th if you want to use the spool holder, and then proceed to add the last 3 spacers. Leave the bottom two holes empty to use to mount the Z-axis to the chassis.

Lay down the rail, then starting at the top hole, add 3d printed spacers to the first 3 holes, omit the 4th if you want to use the spool holder, and then proceed to add the last 3 spacers. Leave the bottom two holes empty to use to mount the Z-axis to the chassis. -

Screw in the rail

Fasten the rail with screws in the holes that you added spacers to.M38mm

Fasten the rail with screws in the holes that you added spacers to.M38mm -

Gather edge connector parts

Cut approximately 50cm of silicone power wire and signal wires.

Cut approximately 50cm of silicone power wire and signal wires. -

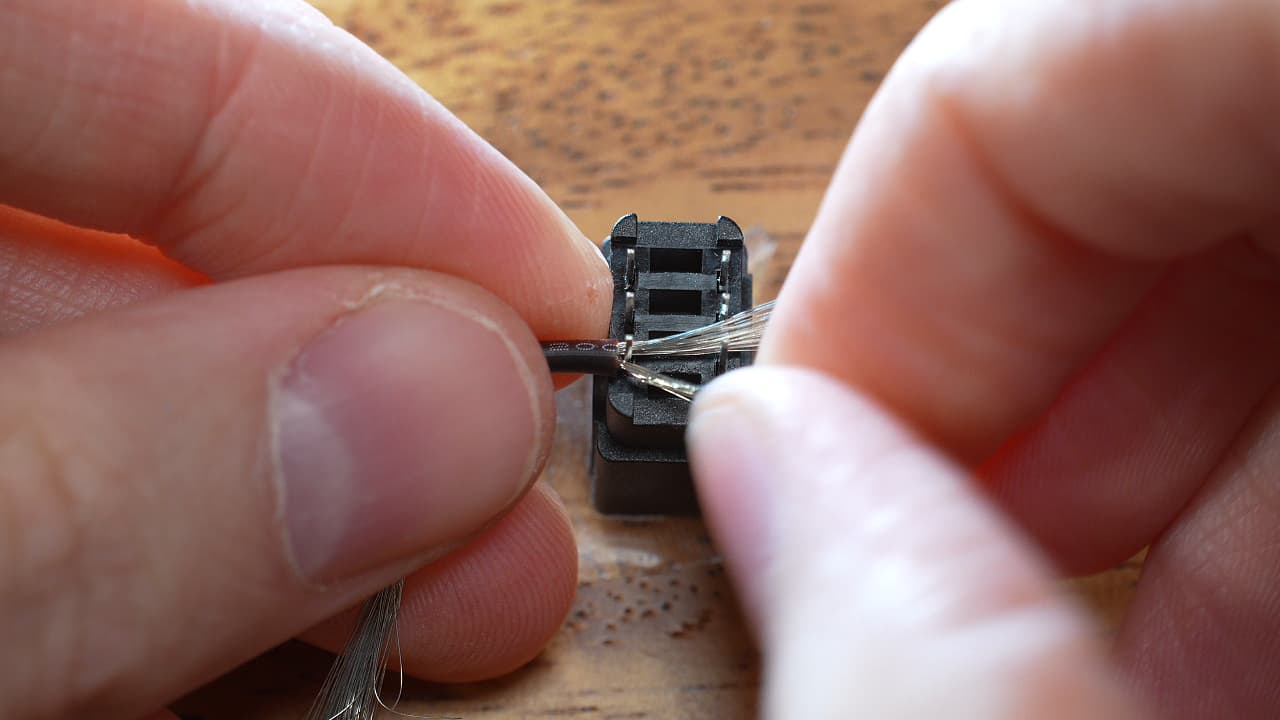

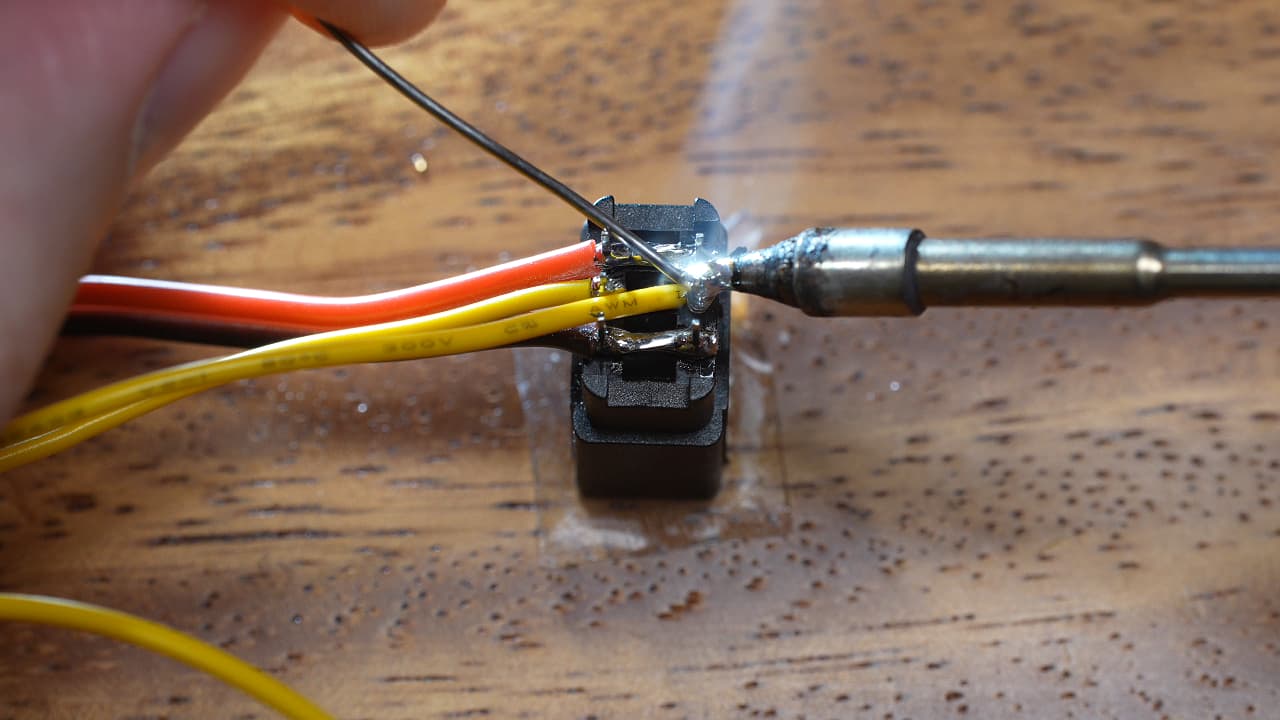

Solder the power wires

Fan out the wire strands, and use the wire to bridge the two conductors as shown. Twist the end. Solder. Trim the excess.

Fan out the wire strands, and use the wire to bridge the two conductors as shown. Twist the end. Solder. Trim the excess. -

Solder the signal wires

Solder two thin gauge signal wires to the two middle conductors.

Solder two thin gauge signal wires to the two middle conductors. -

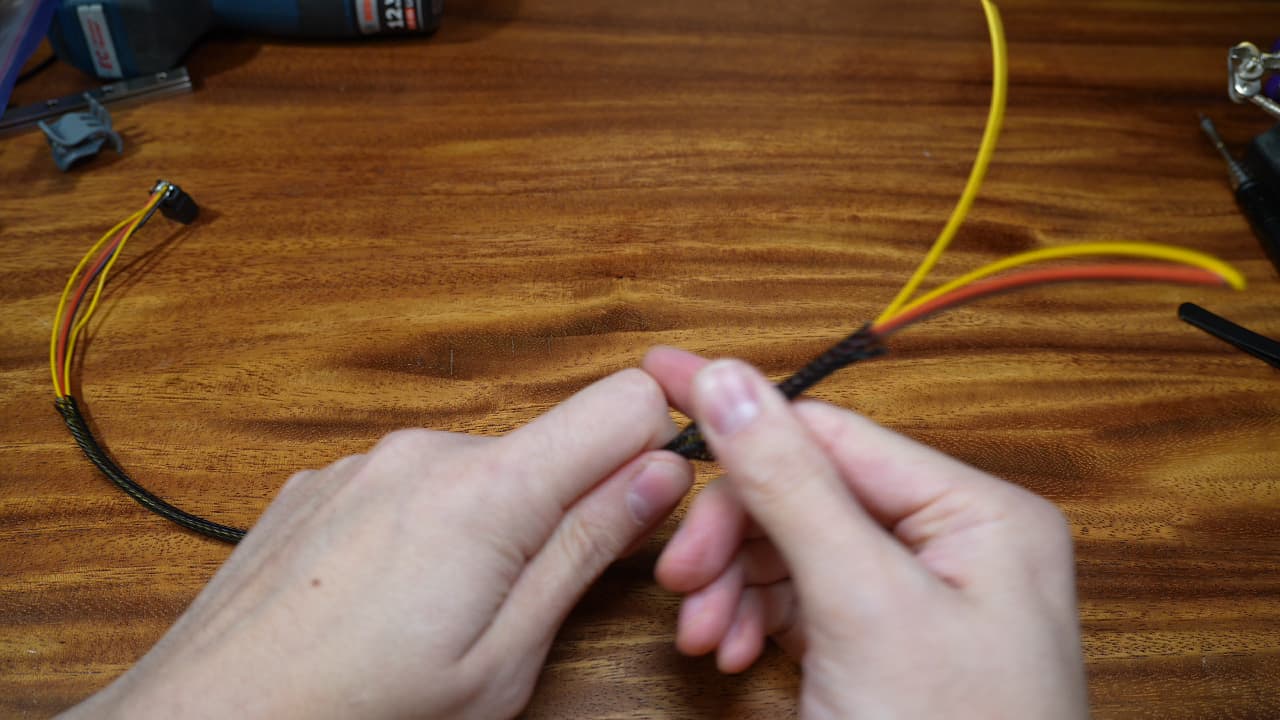

Sleeve the wires

Cut the wire sleeve to 32cm and finesse it onto the wires.

Cut the wire sleeve to 32cm and finesse it onto the wires. -

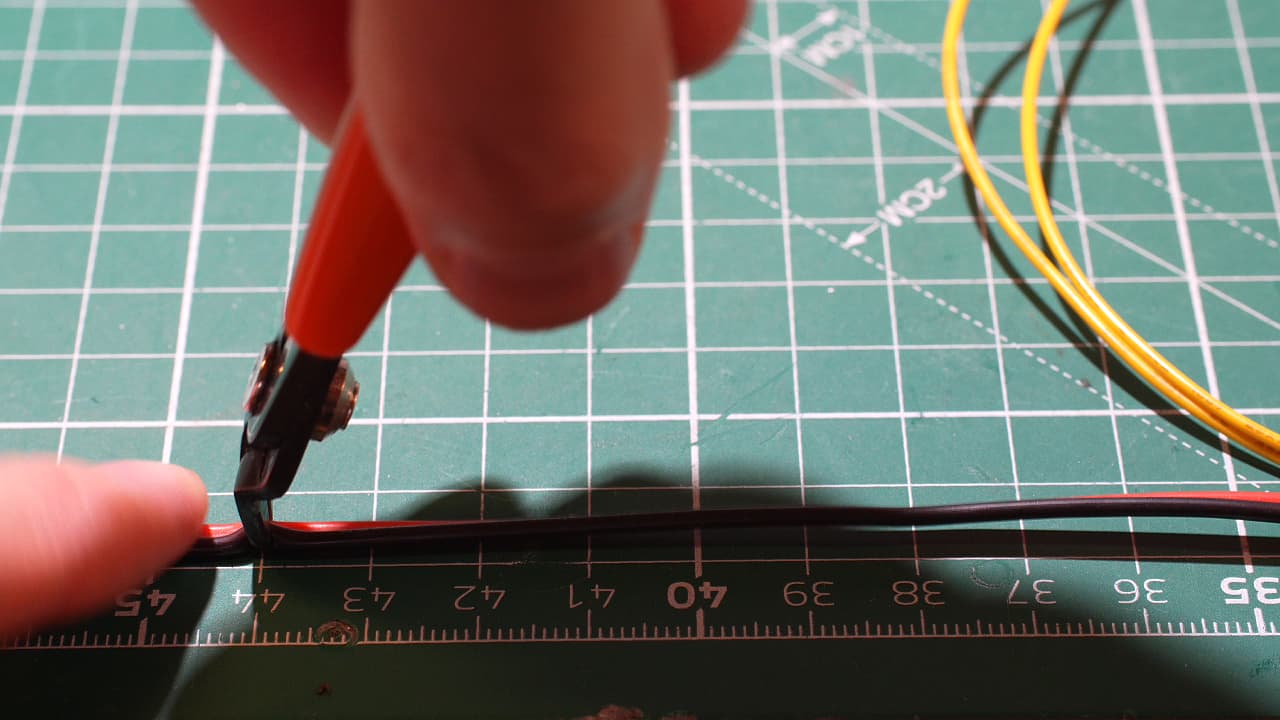

Cut the wires

Cut the power wire to 44cm and the signal wires to 42cm.

Cut the power wire to 44cm and the signal wires to 42cm. -

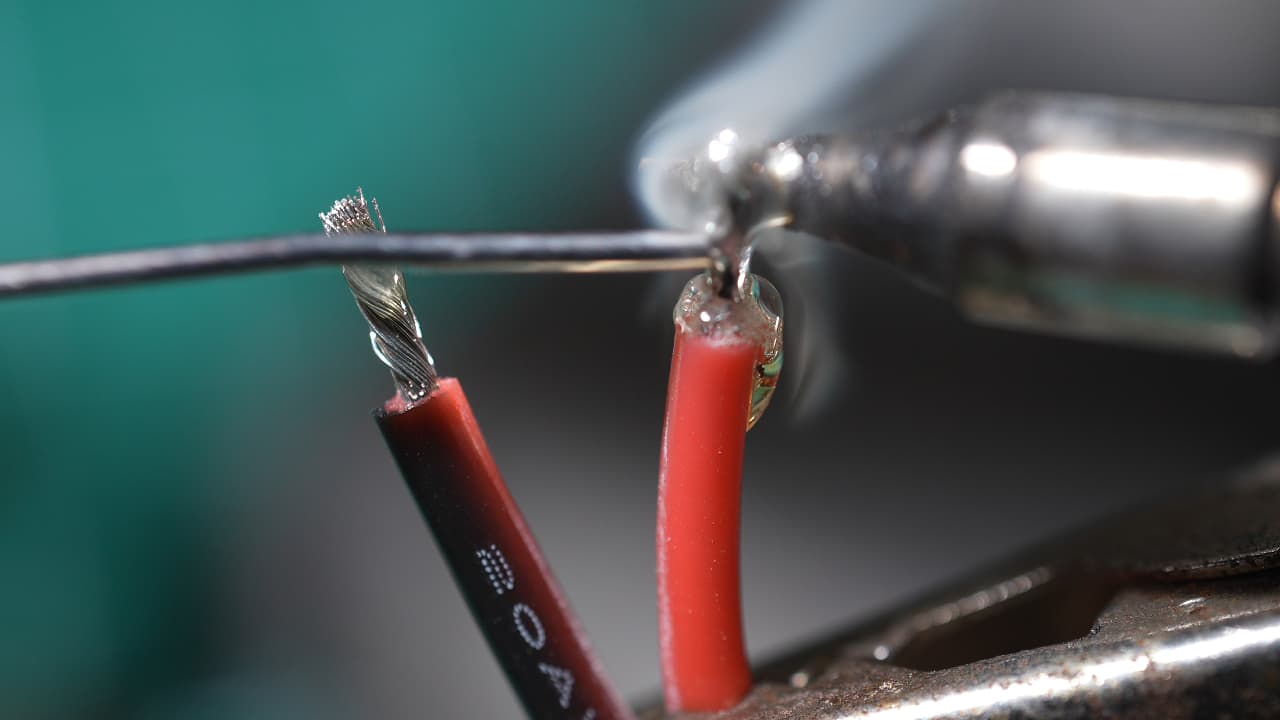

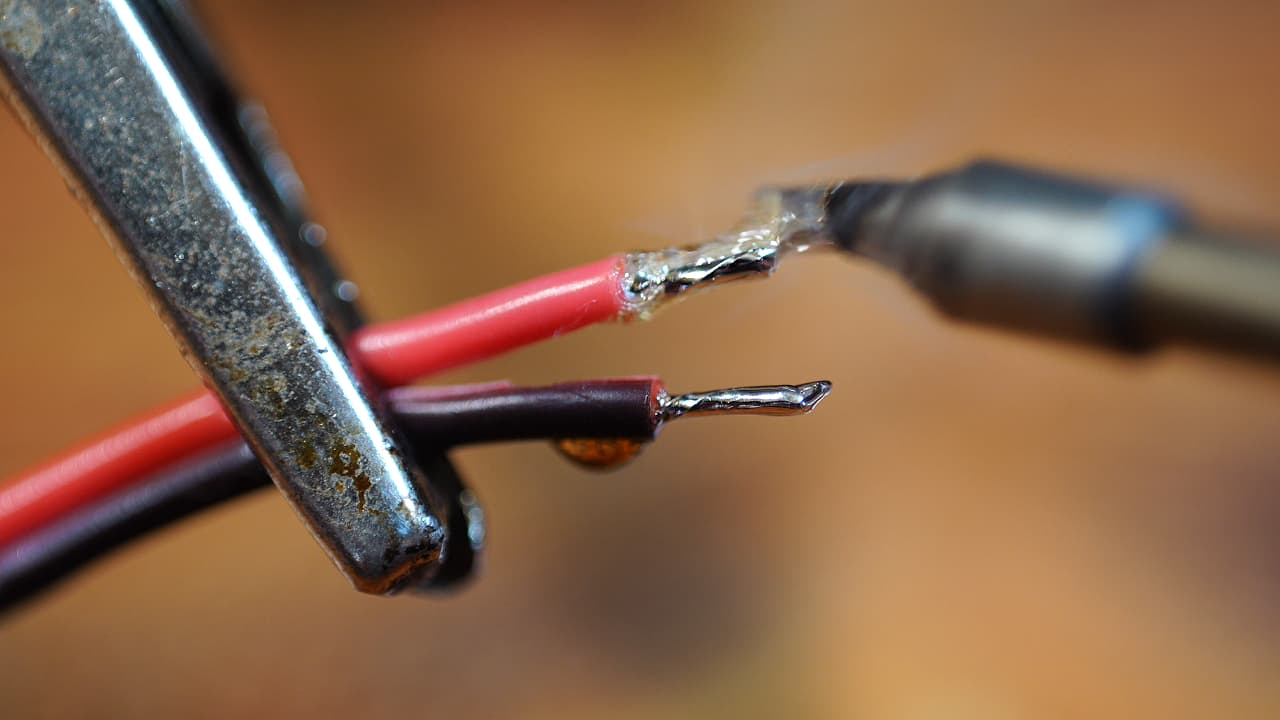

Tin the power wires

Strip 5mm of insulation from the power wires and tin them.

Strip 5mm of insulation from the power wires and tin them. -

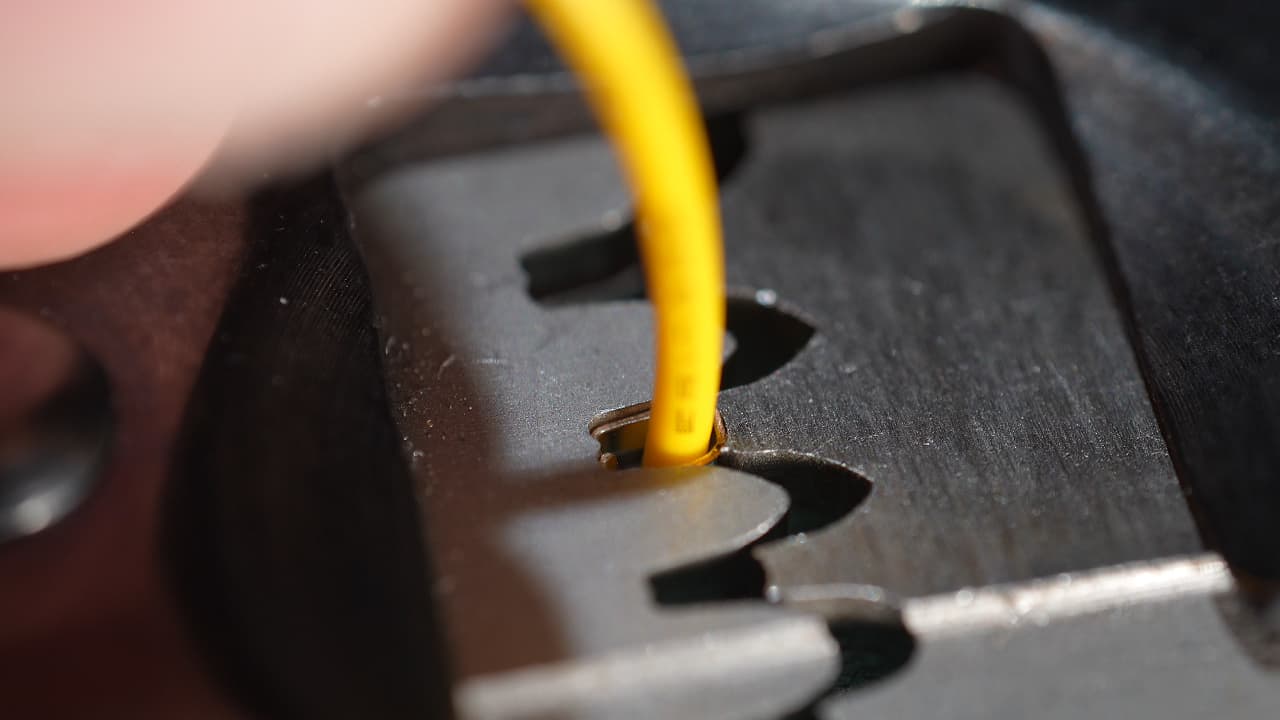

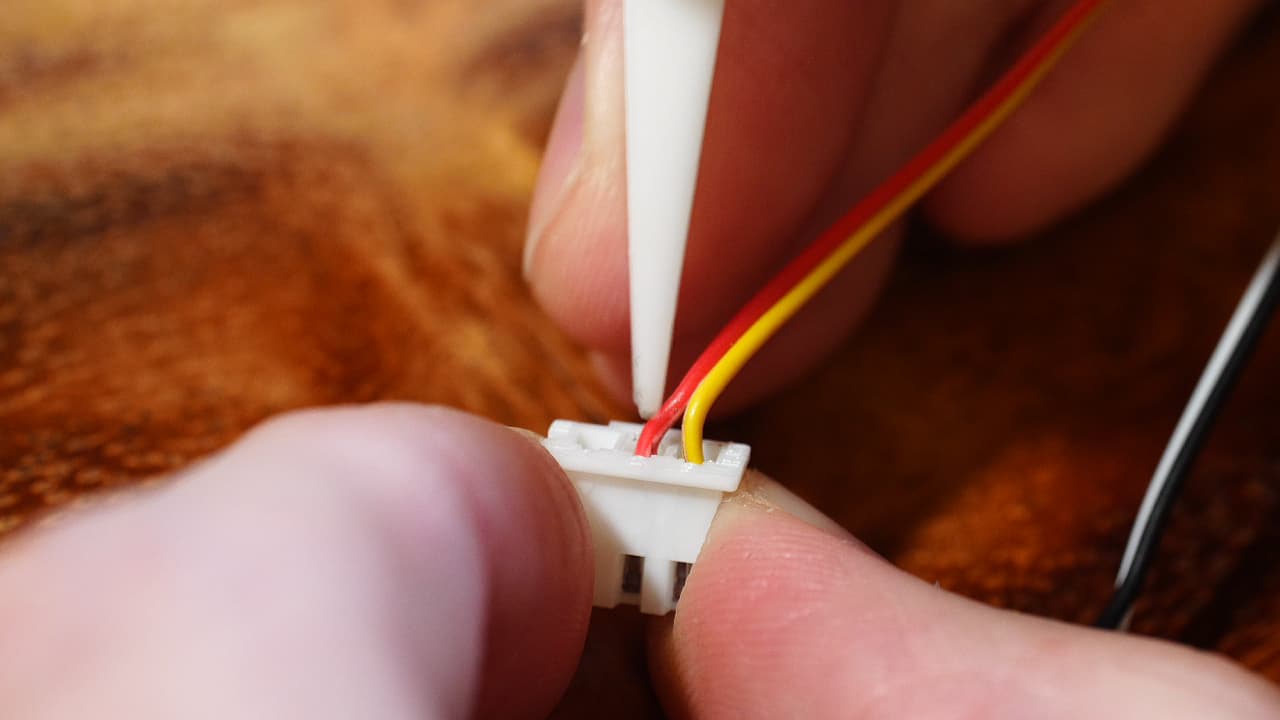

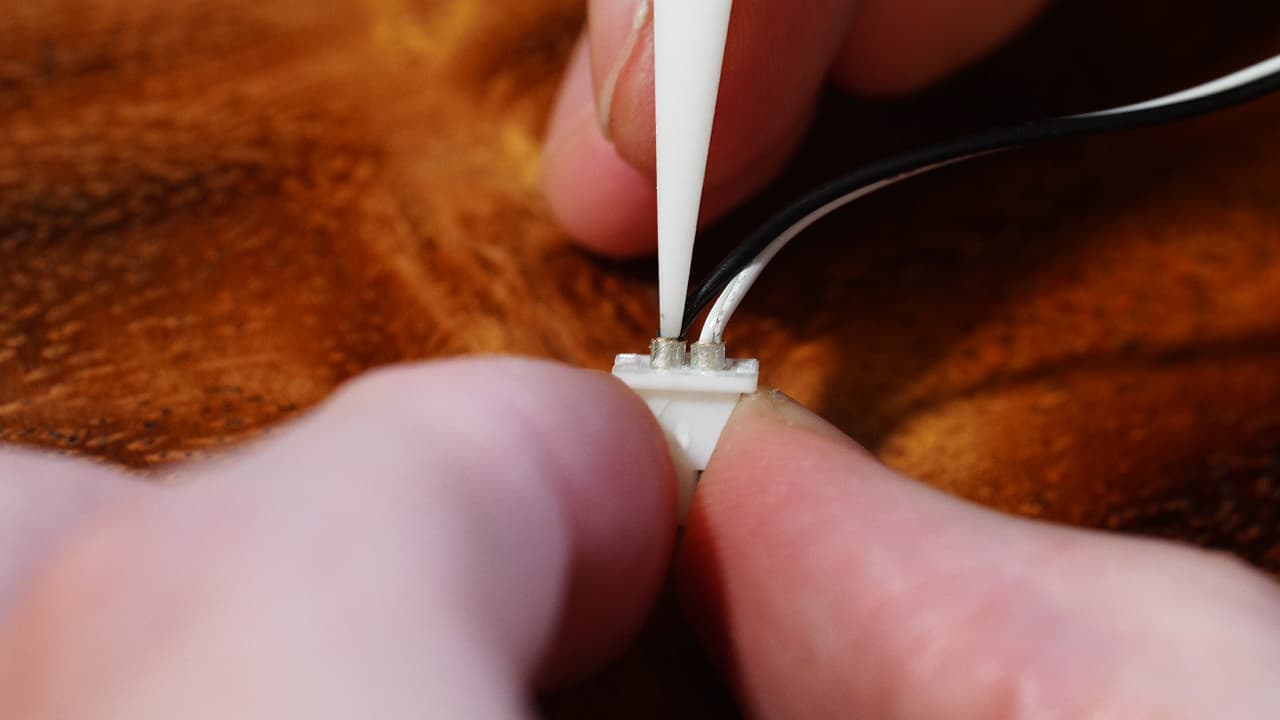

Crimp signal wires

Crimp the two signal wires. Learn how to crimp goooood here.

Crimp the two signal wires. Learn how to crimp goooood here. -

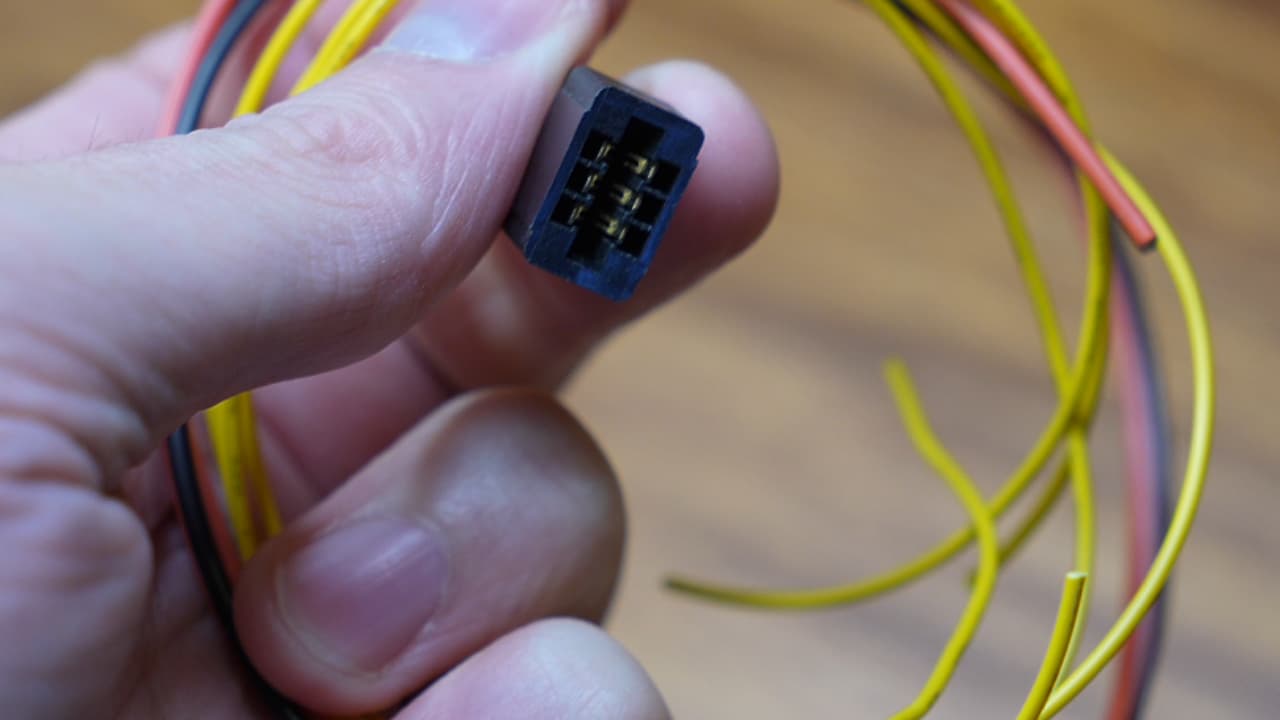

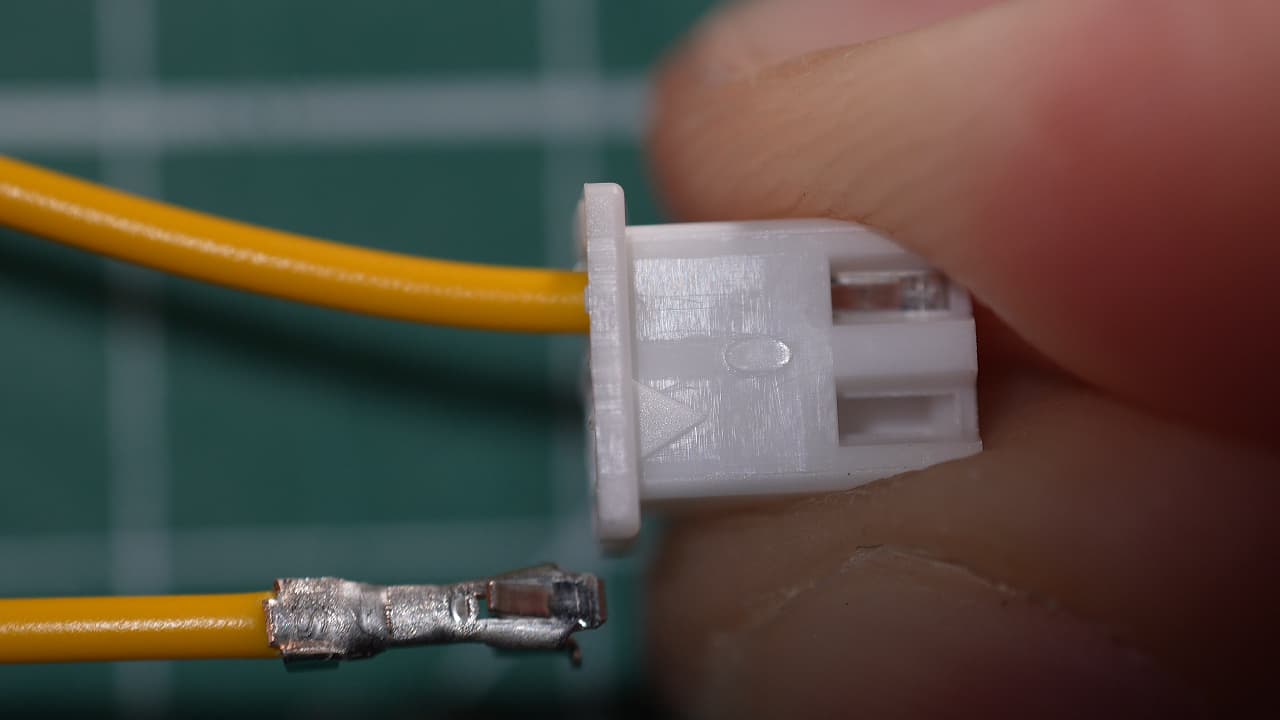

Insert connector

Insert the two crimped signal wires into the JST connector. Polarity does not matter.

Insert the two crimped signal wires into the JST connector. Polarity does not matter. -

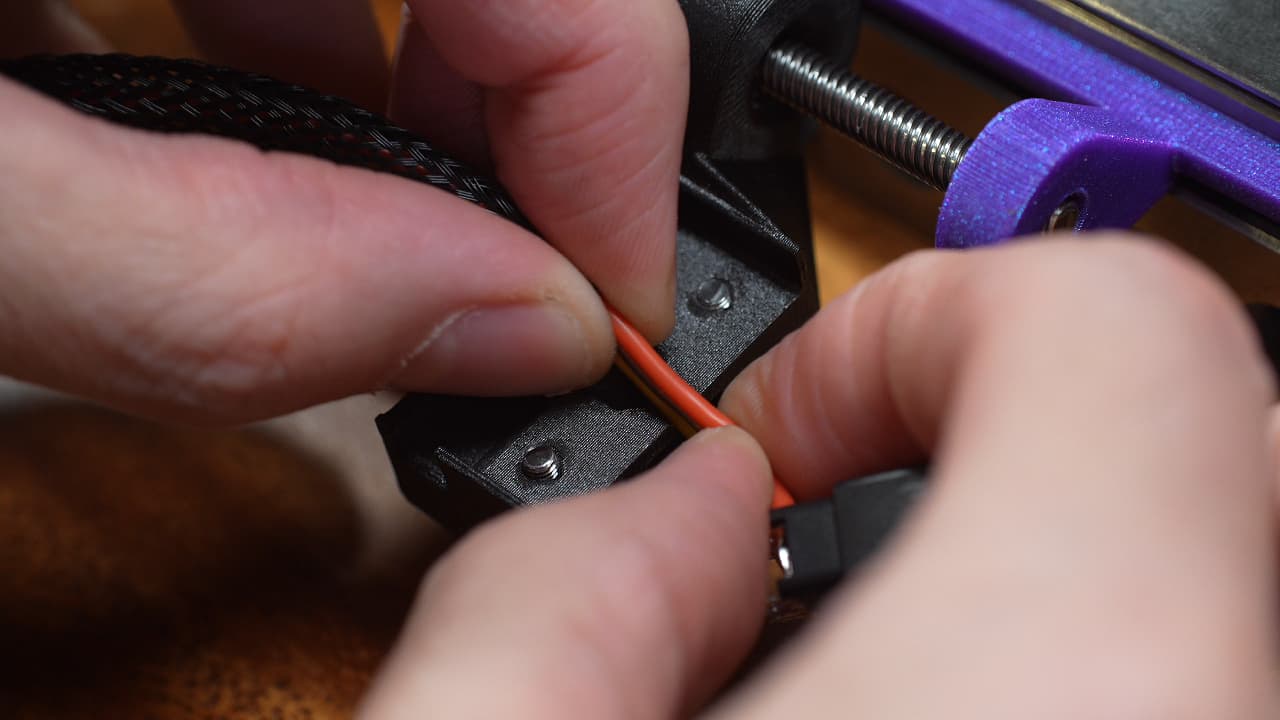

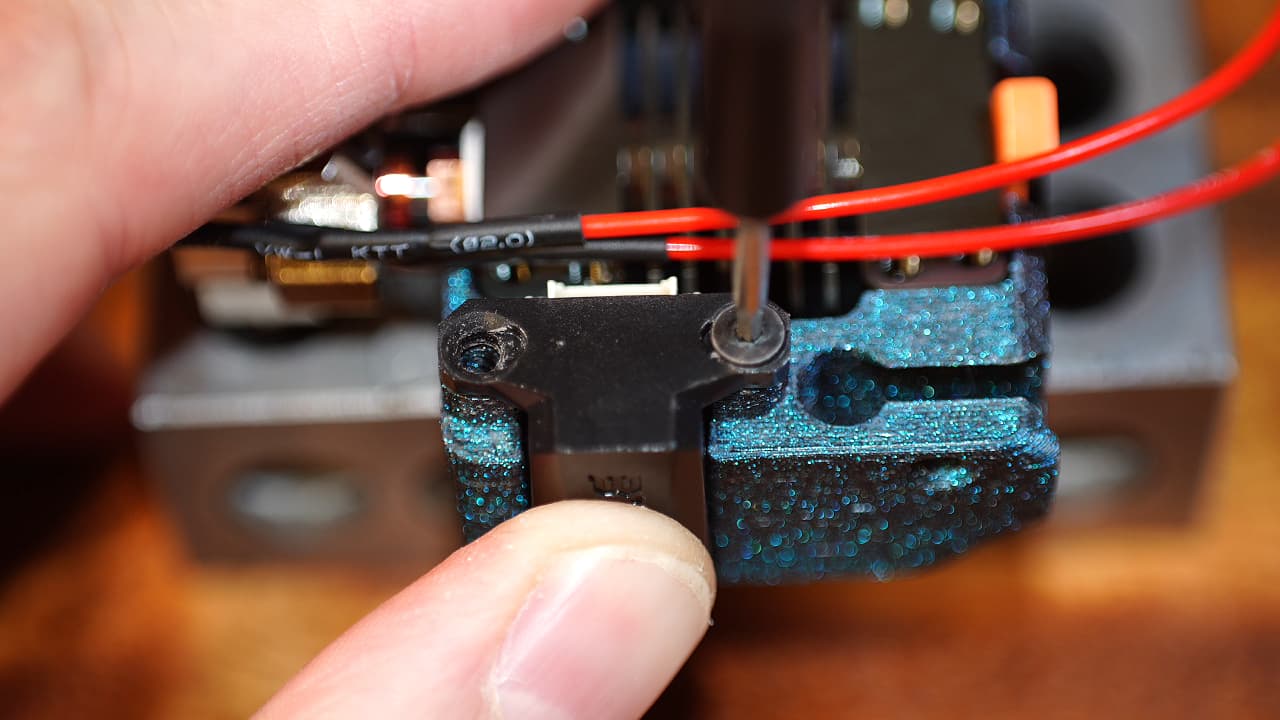

Slide in edge connector wire

Slide the wires in through the slot in the bracket and press the edge connector into place.

Slide the wires in through the slot in the bracket and press the edge connector into place. -

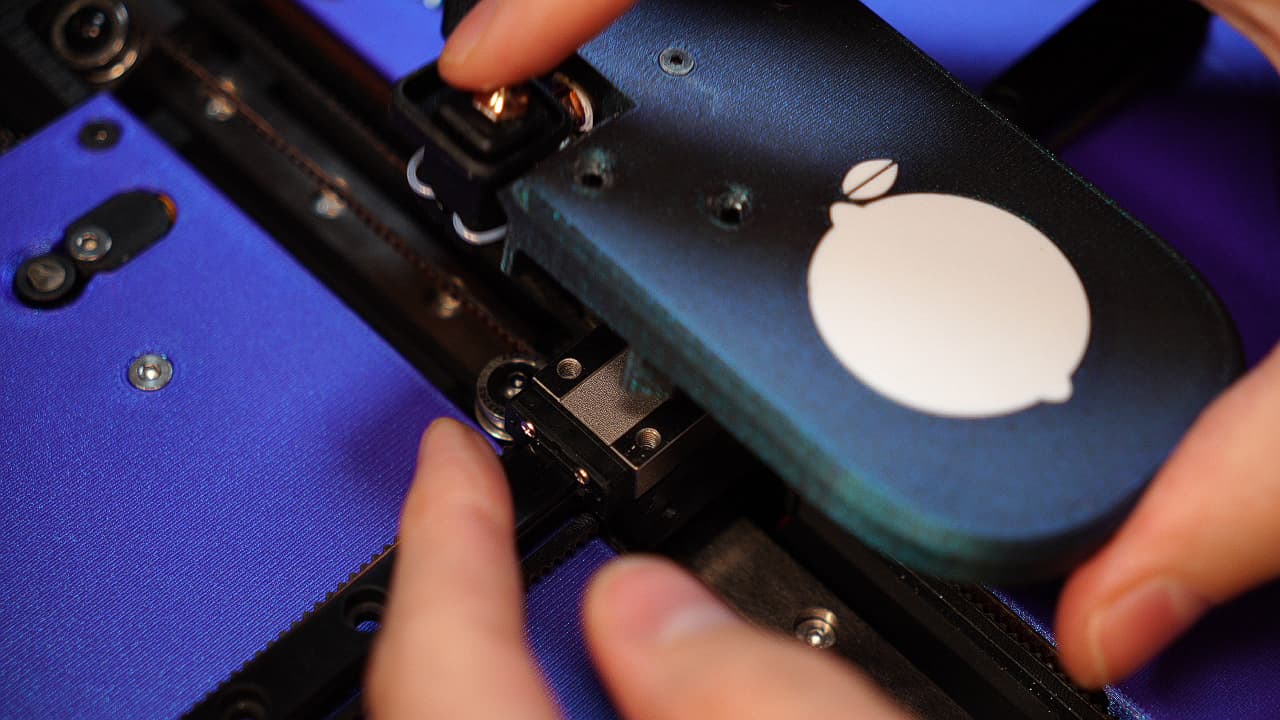

Tighten bracket

Tighten the bracket on to the carriage with two screws.M325mmPicture shows button head screws.

Tighten the bracket on to the carriage with two screws.M325mmPicture shows button head screws. -

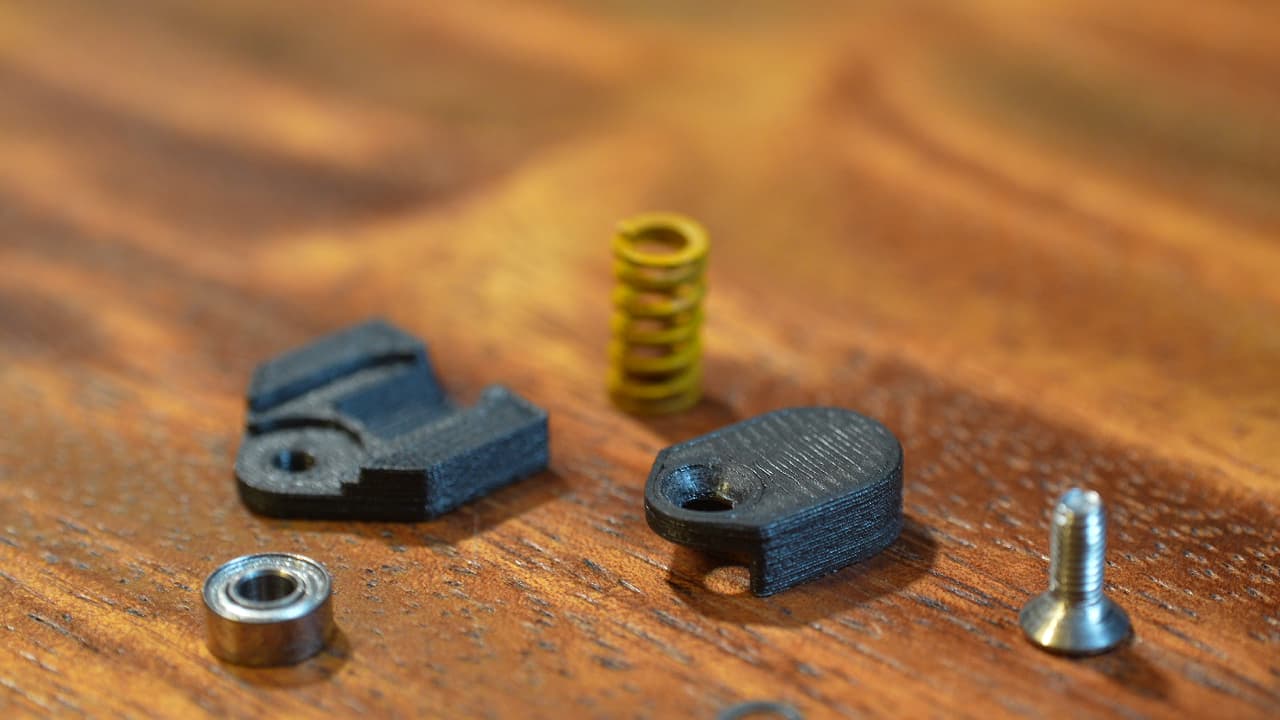

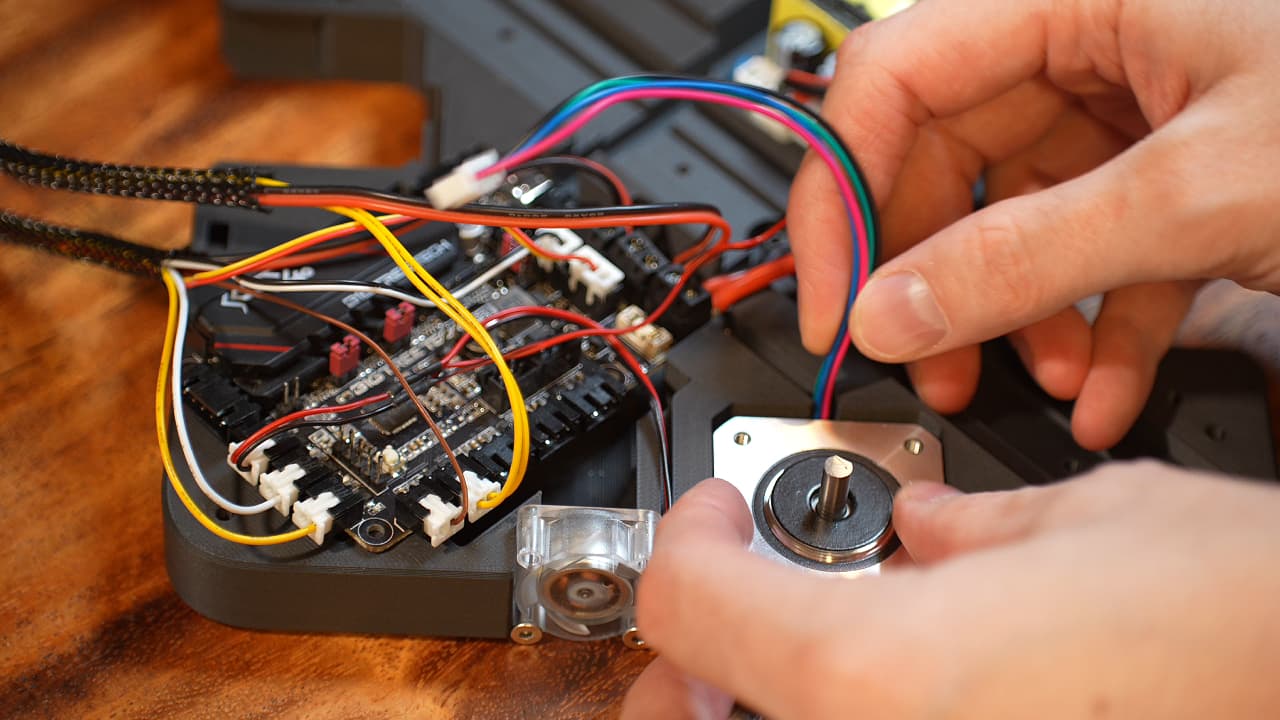

Gather Lemonstruder parts

Printed top & bottom halves, yellow spring, 8mm countersunk screw, small bearing, 2 small shims, and super glue.

Printed top & bottom halves, yellow spring, 8mm countersunk screw, small bearing, 2 small shims, and super glue. -

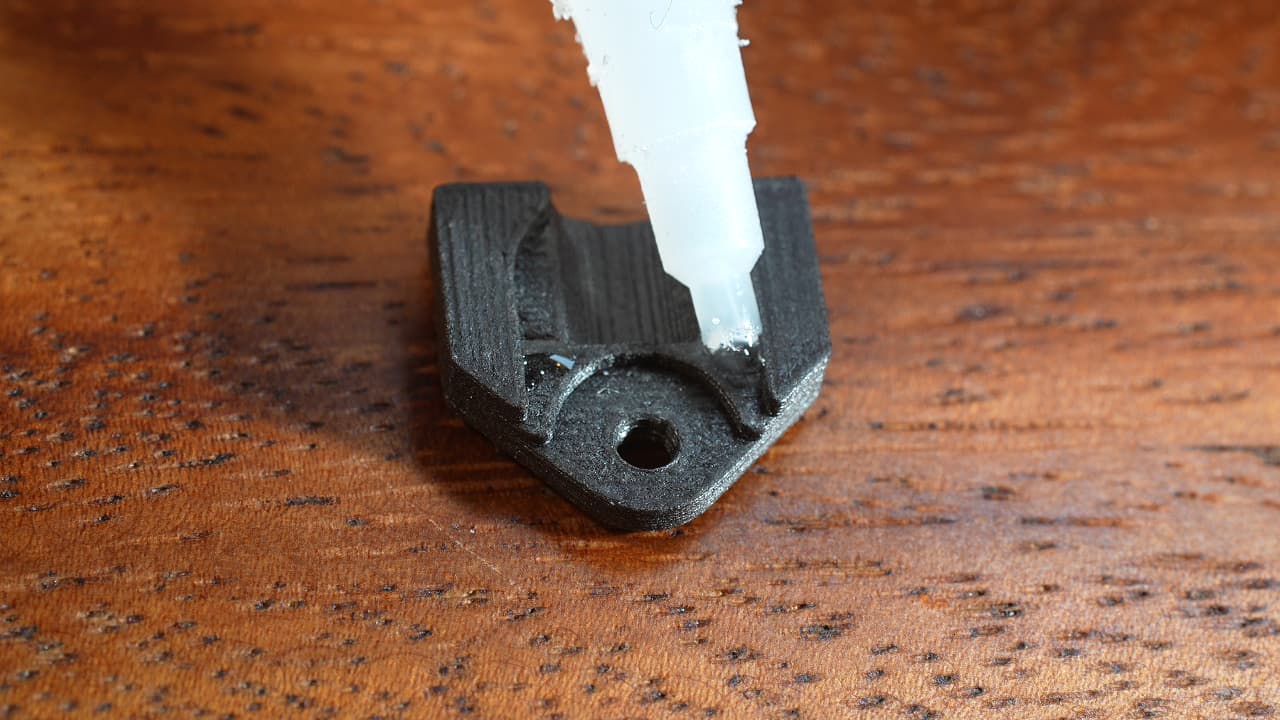

Glue halves together

Dap two tiny dots of super glue as pictured.

Dap two tiny dots of super glue as pictured. -

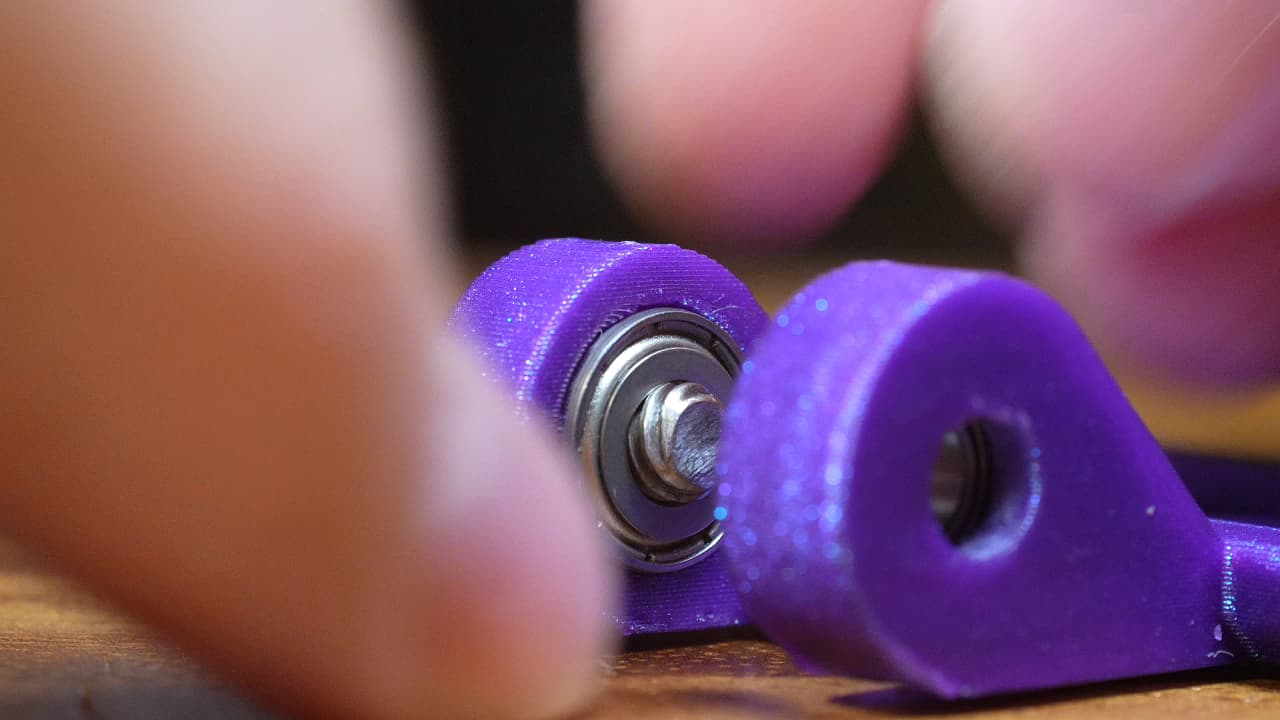

Insert the first shim

Insert the first shim, using a small screw to help guide it in. This shim will allow the bearing to rotate against the plastic housing.

Insert the first shim, using a small screw to help guide it in. This shim will allow the bearing to rotate against the plastic housing. -

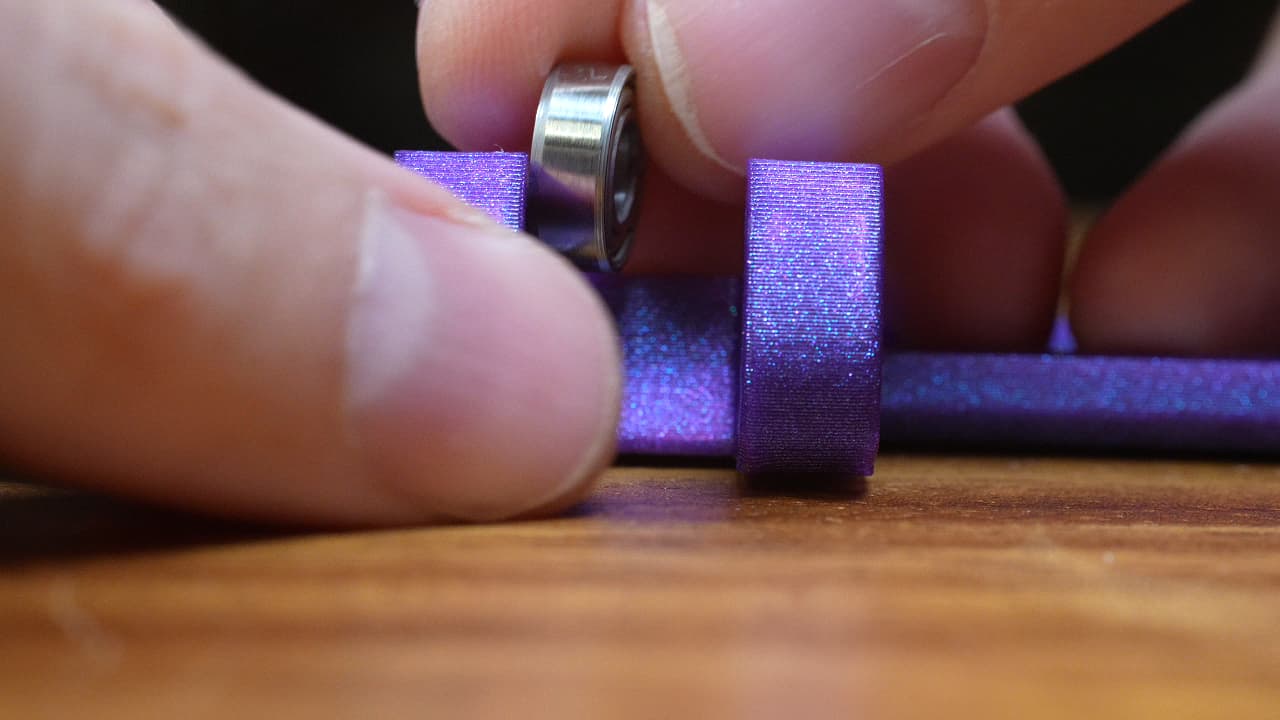

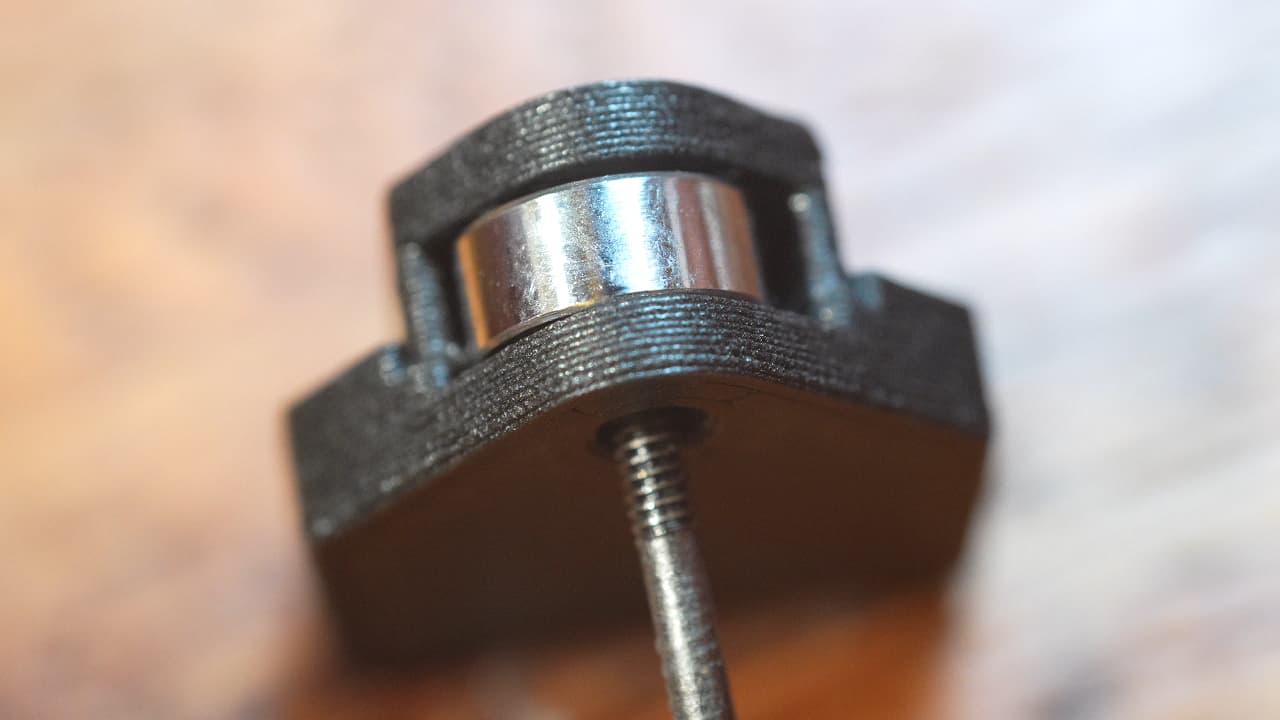

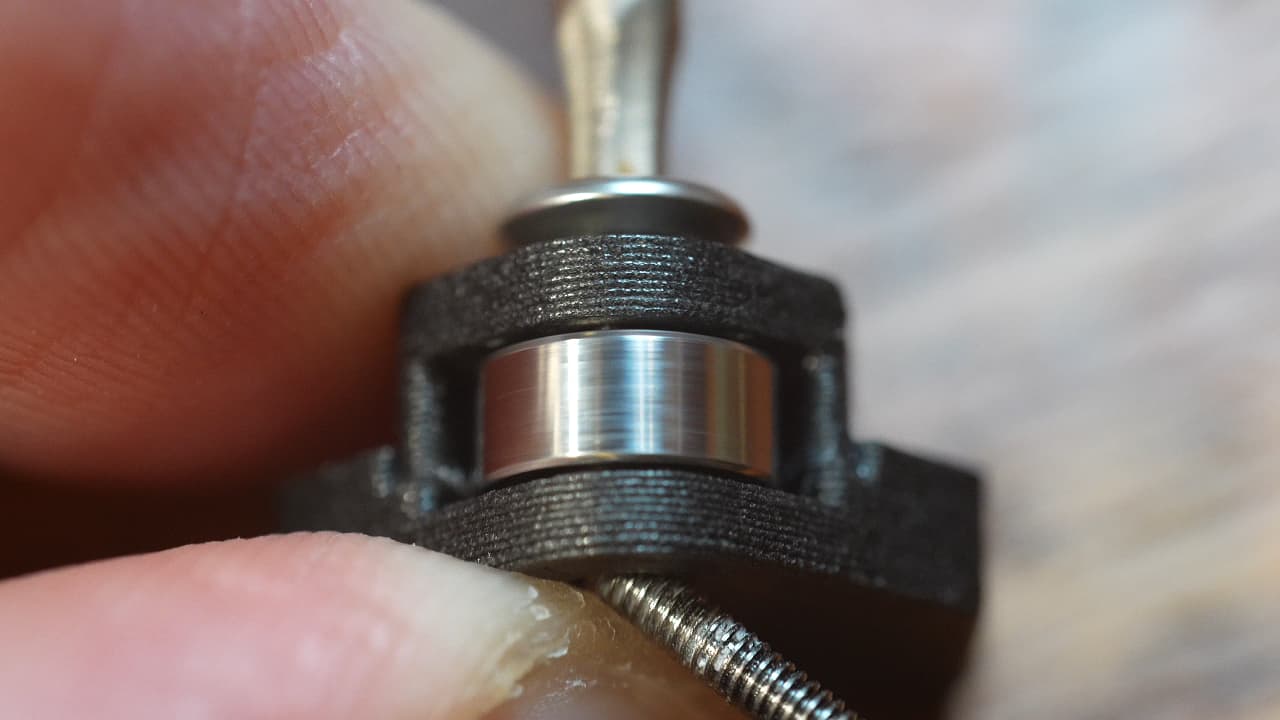

Insert the bearing

Insert the bearing on top of the shim.

Insert the bearing on top of the shim. -

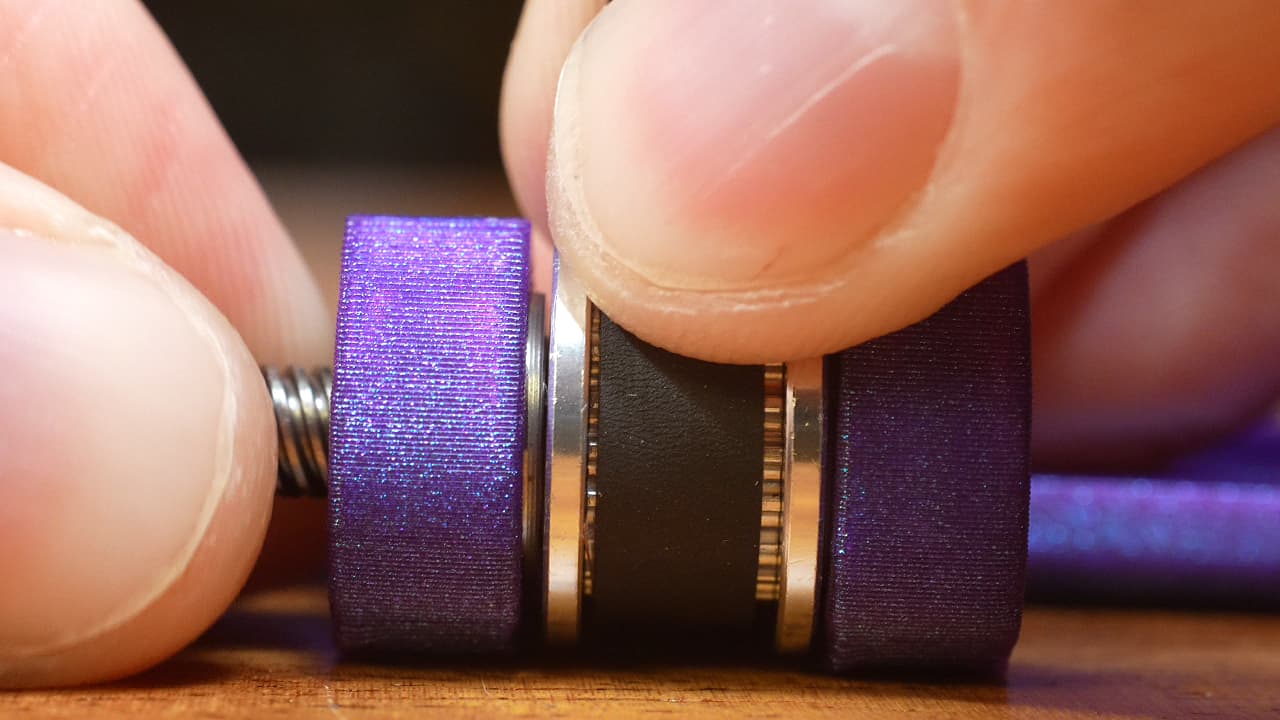

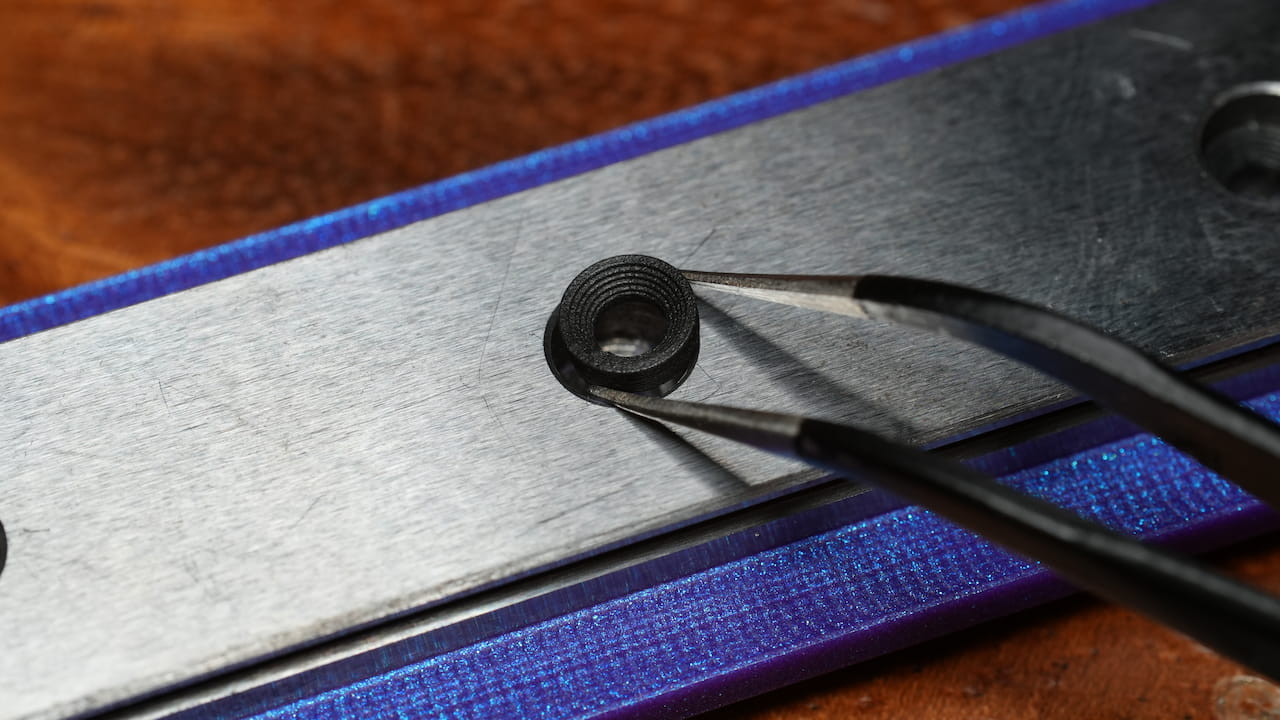

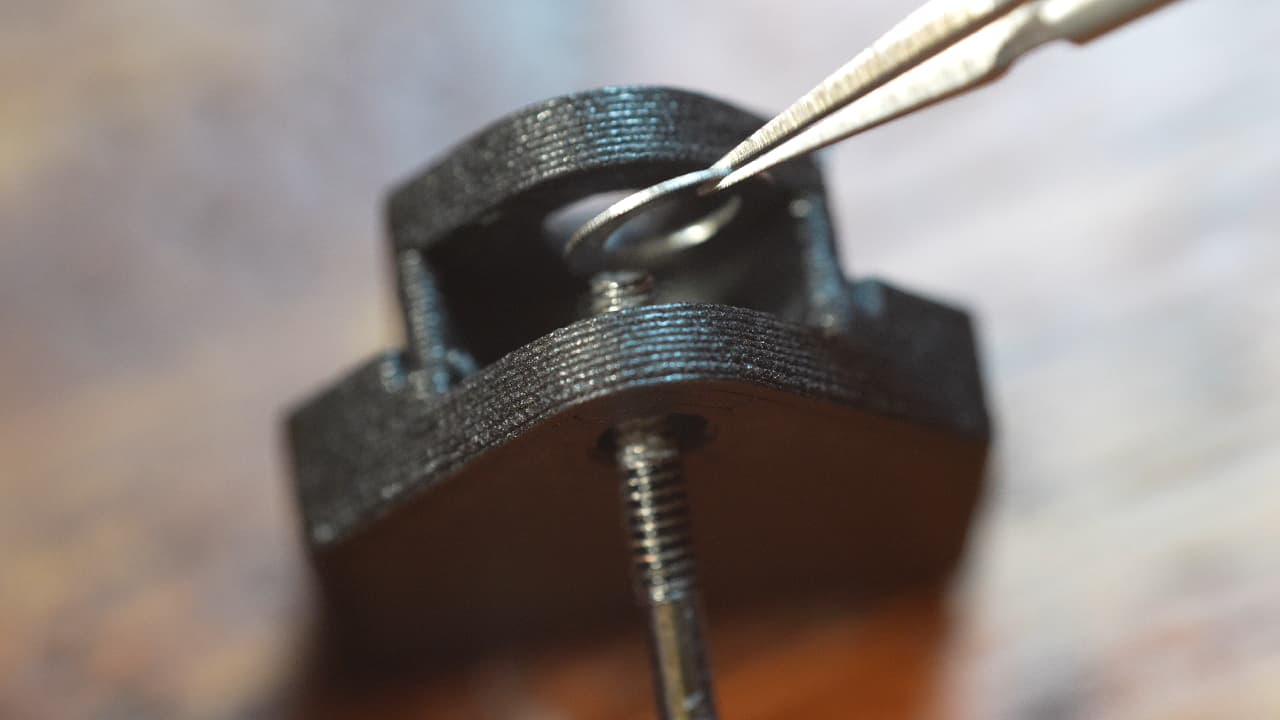

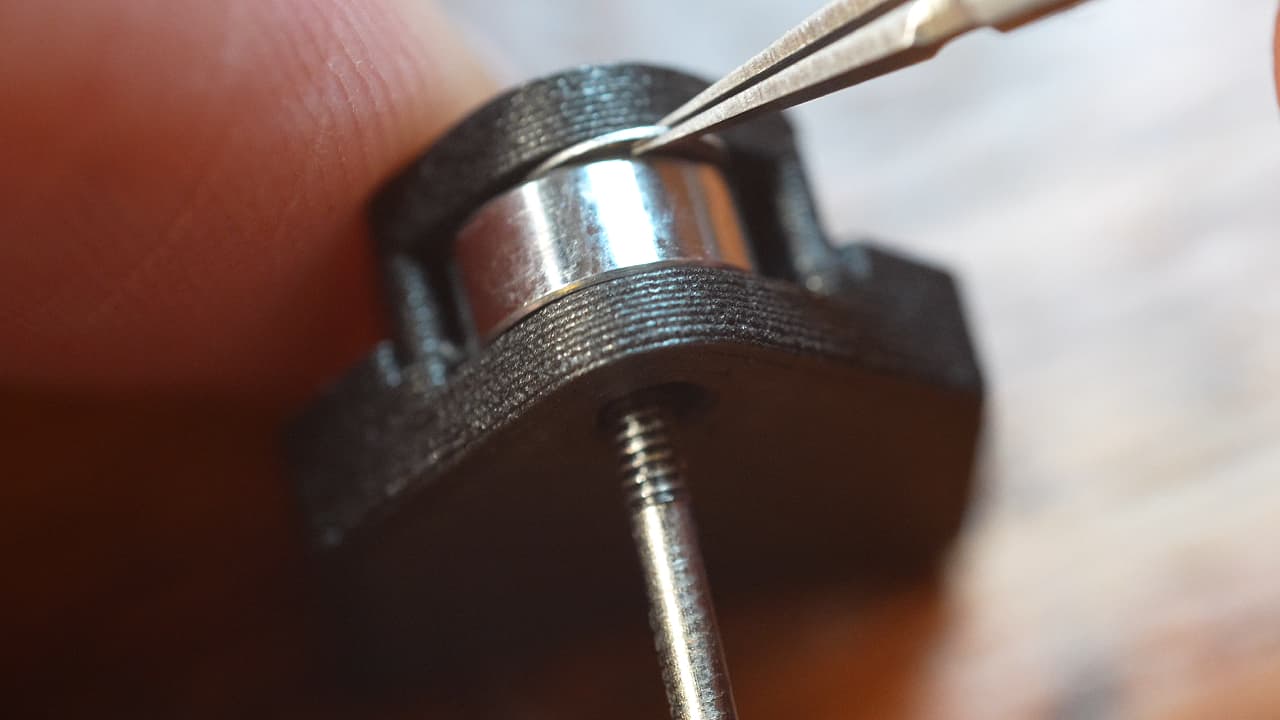

Insert the second shim

Using tweezers, insert the second shim between the bearing and the plastic housing.

Using tweezers, insert the second shim between the bearing and the plastic housing. -

Insert the screw

Insert the screw, pushing out the small screw. This screw is designed to not fit completely flush.M38mm

Insert the screw, pushing out the small screw. This screw is designed to not fit completely flush.M38mm -

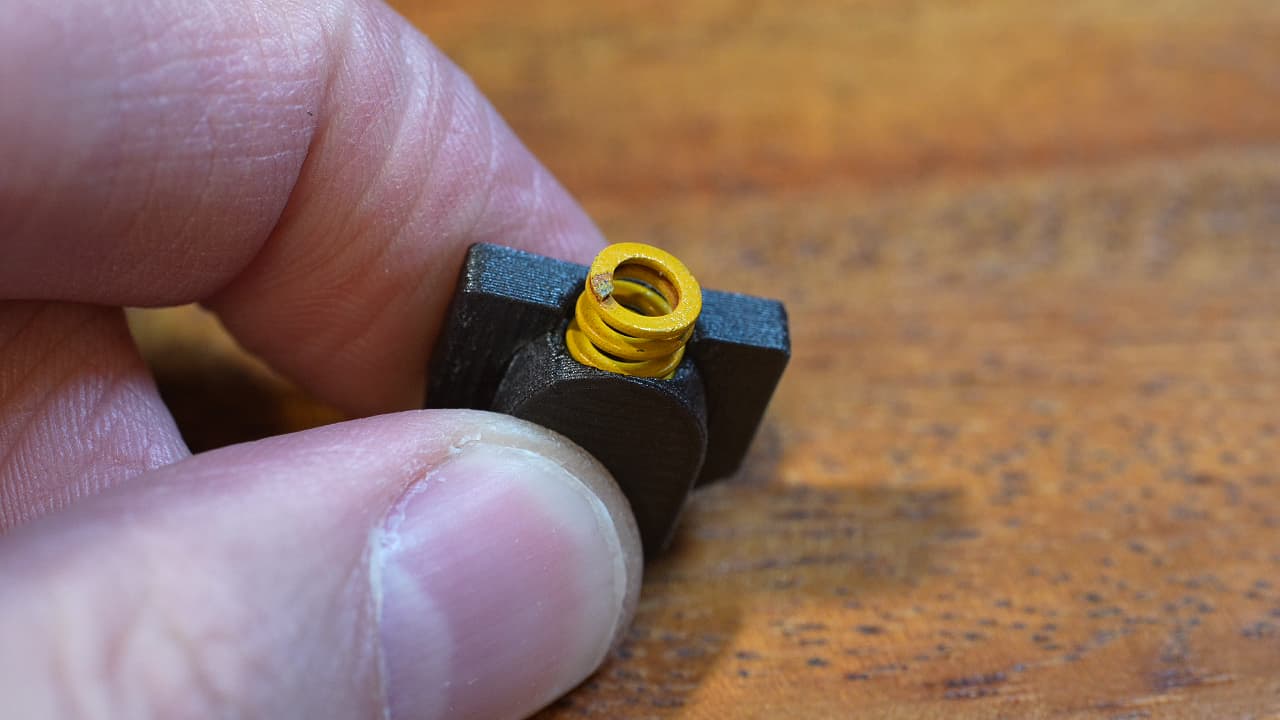

Insert the spring

Insert the unmodified yellow boinger.

Insert the unmodified yellow boinger. -

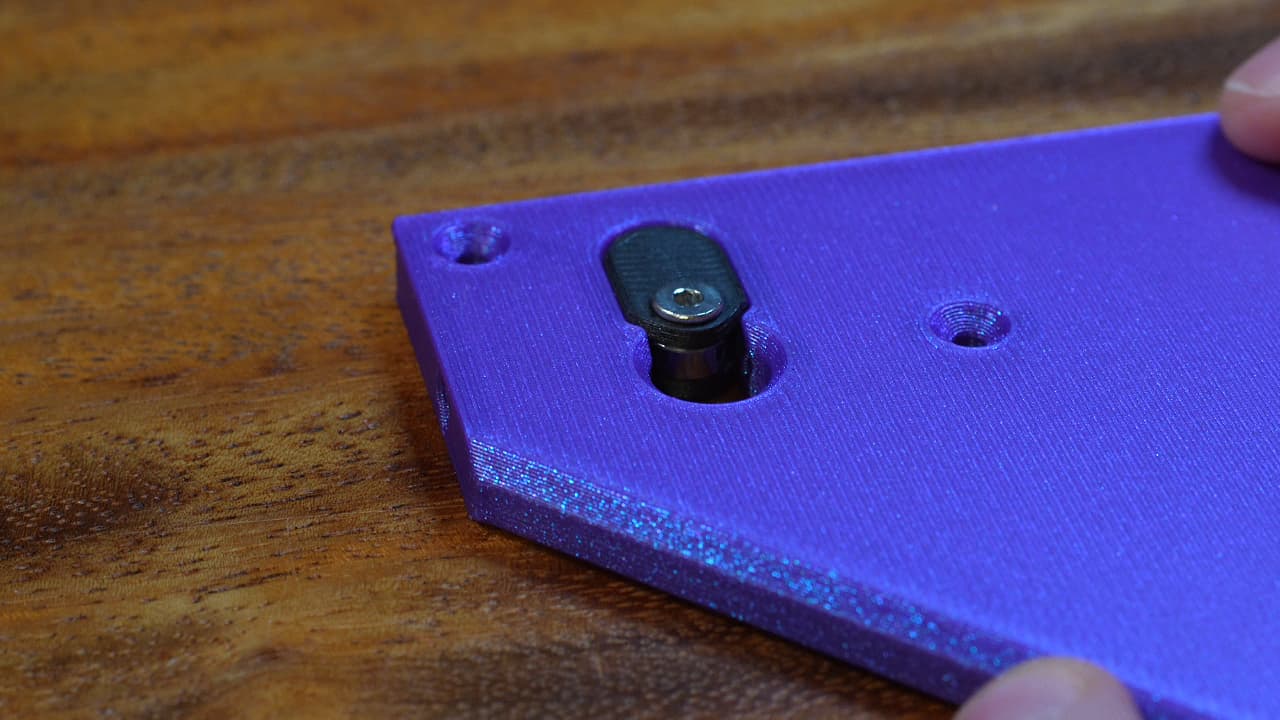

Insert the Lemonstruder

Insert the Lemonstruder into the left top plate.

Insert the Lemonstruder into the left top plate. -

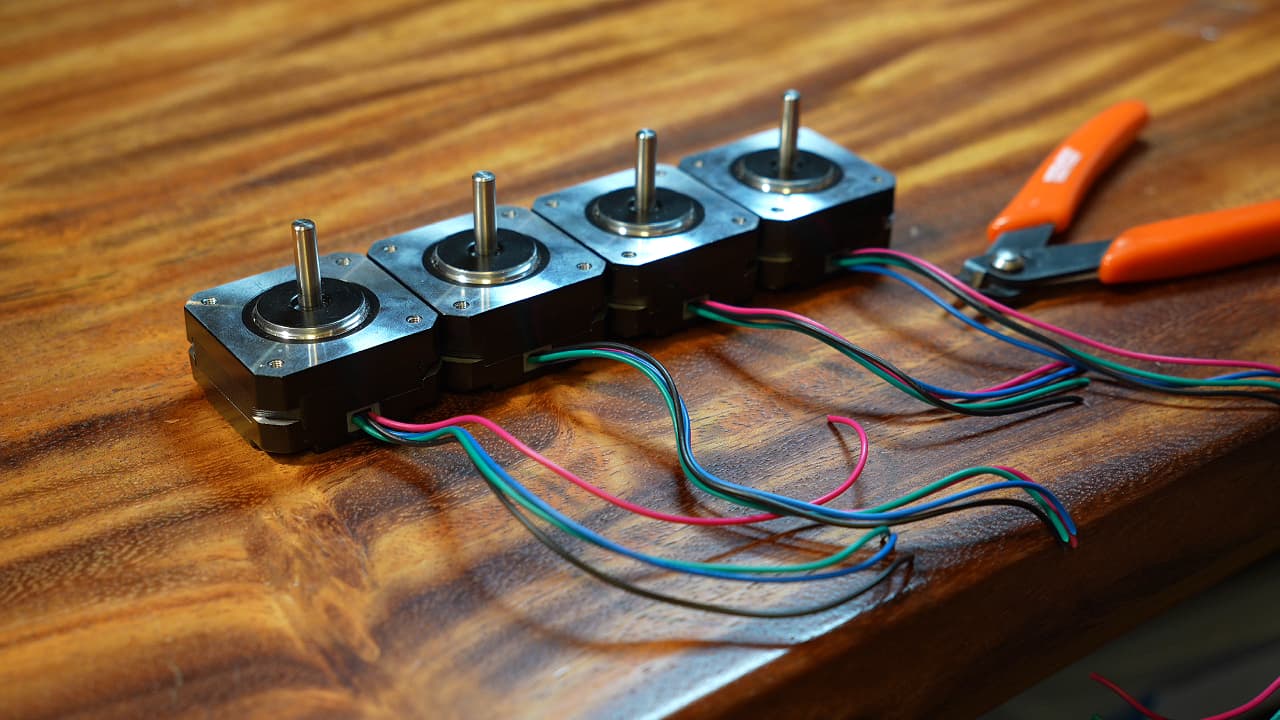

Cut motor wires

Cut the motor wires to the lengths 15cm, 15cm, 10cm, 23cm.

Cut the motor wires to the lengths 15cm, 15cm, 10cm, 23cm. -

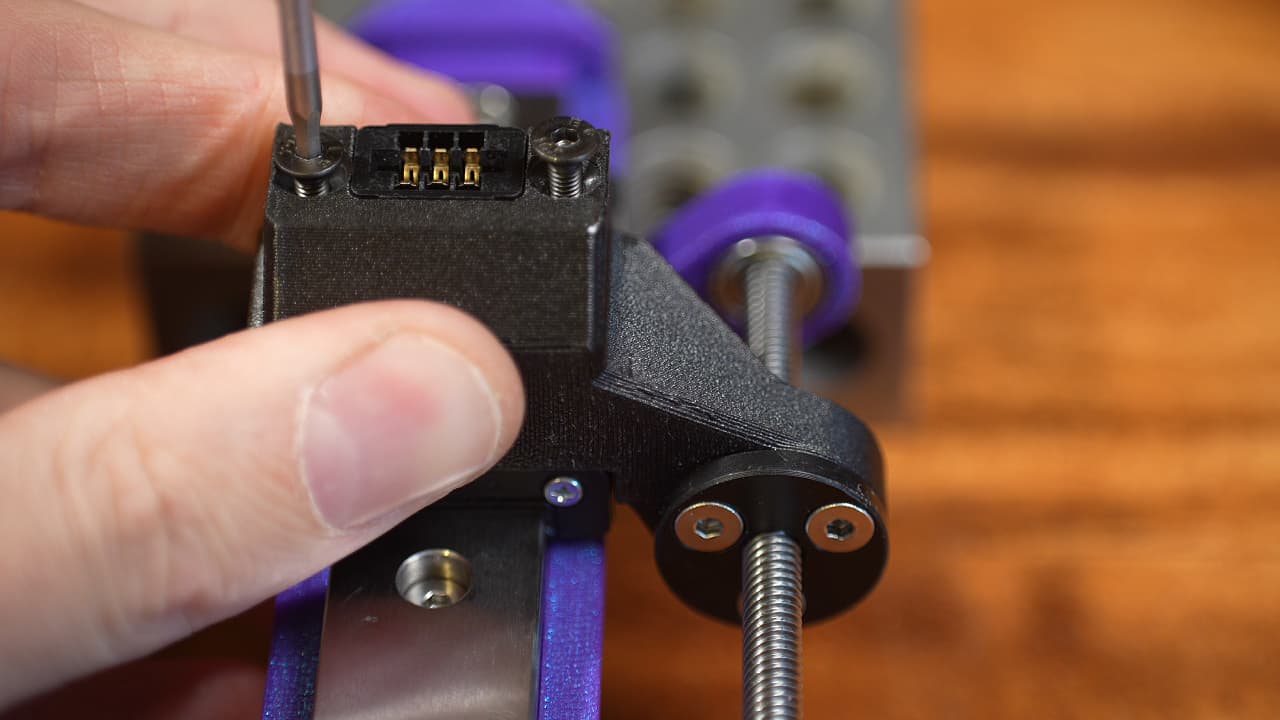

Crimp motor wires

Crimp every motor wire.

Crimp every motor wire. -

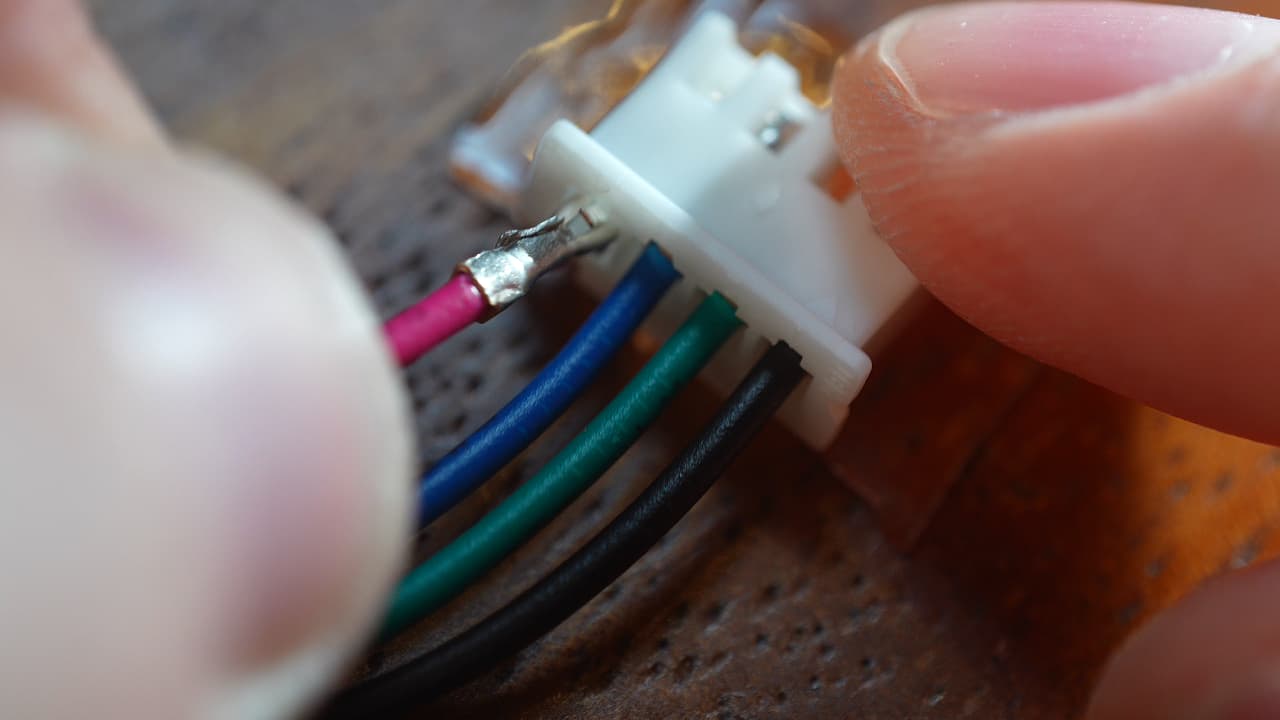

Insert the crimps into the connector

Starting from the triangle mark, go in order of black, green, blue, red.

Starting from the triangle mark, go in order of black, green, blue, red. -

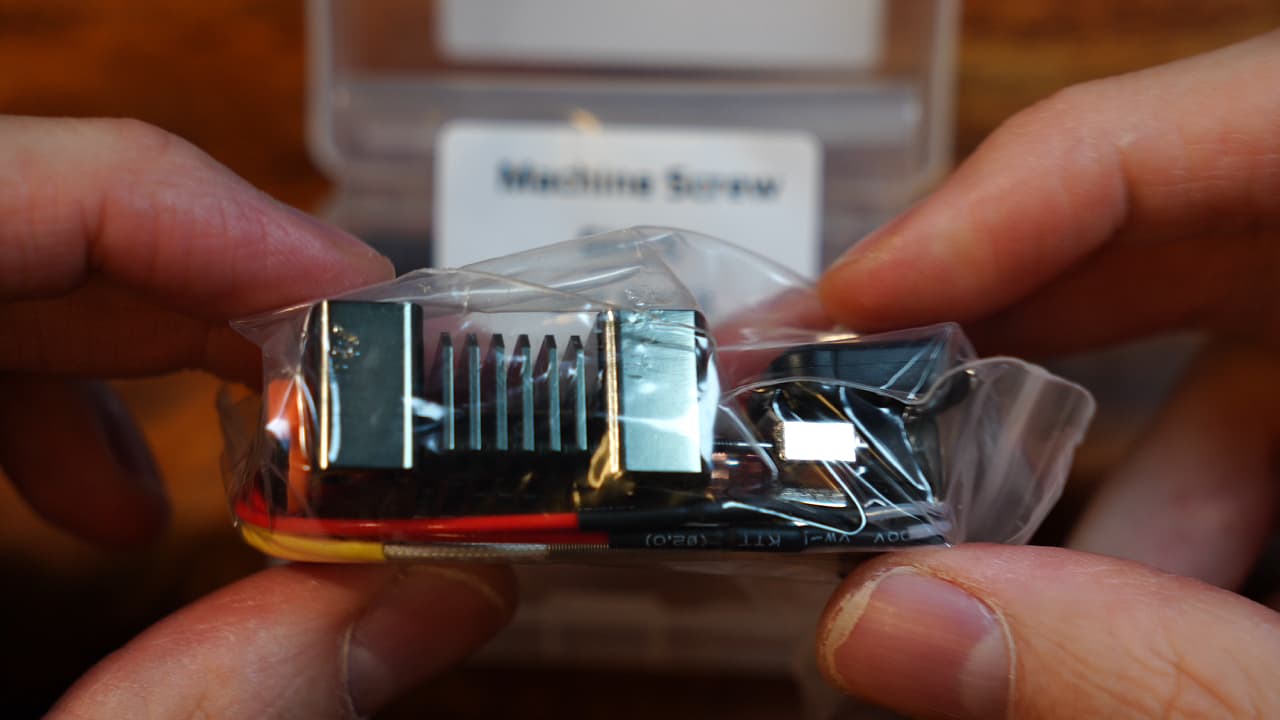

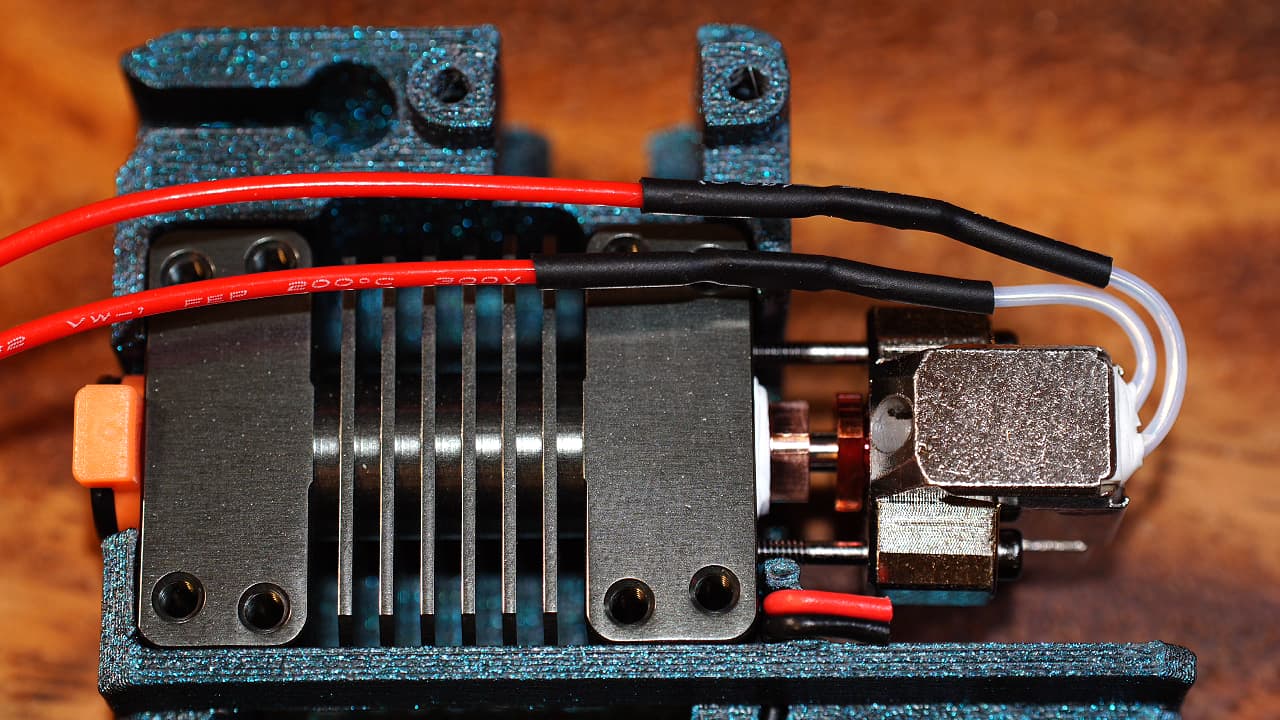

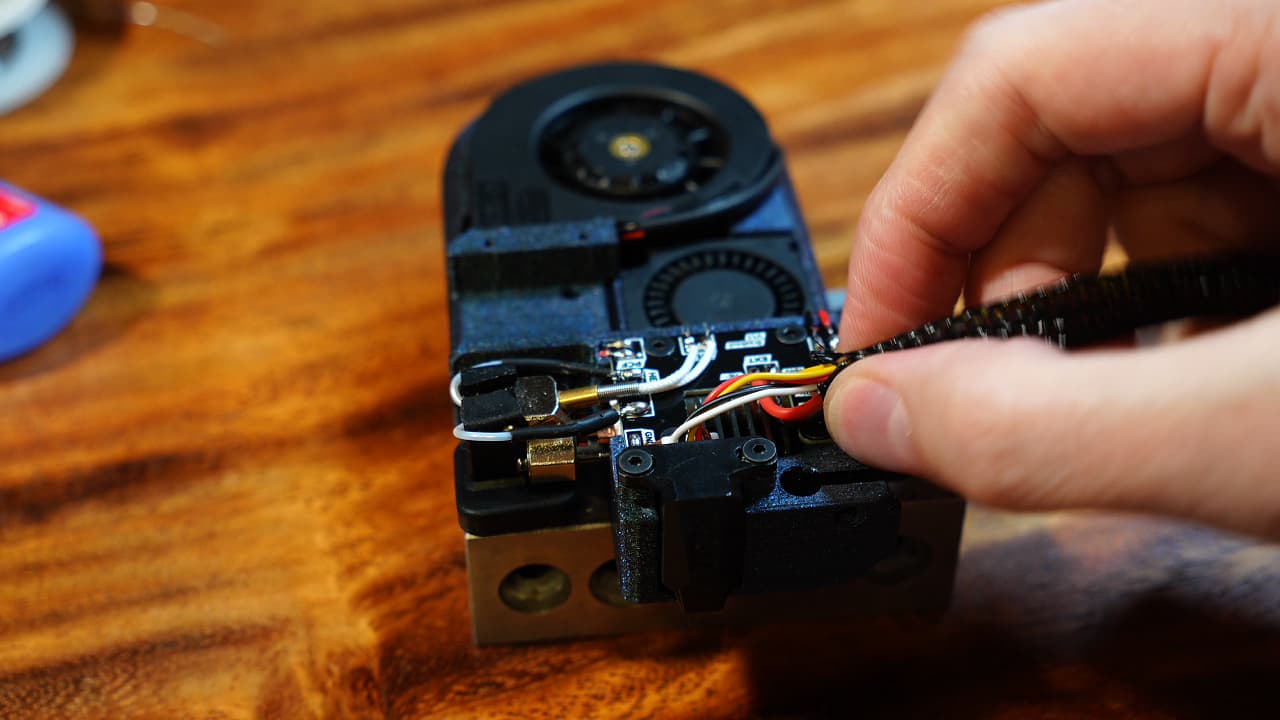

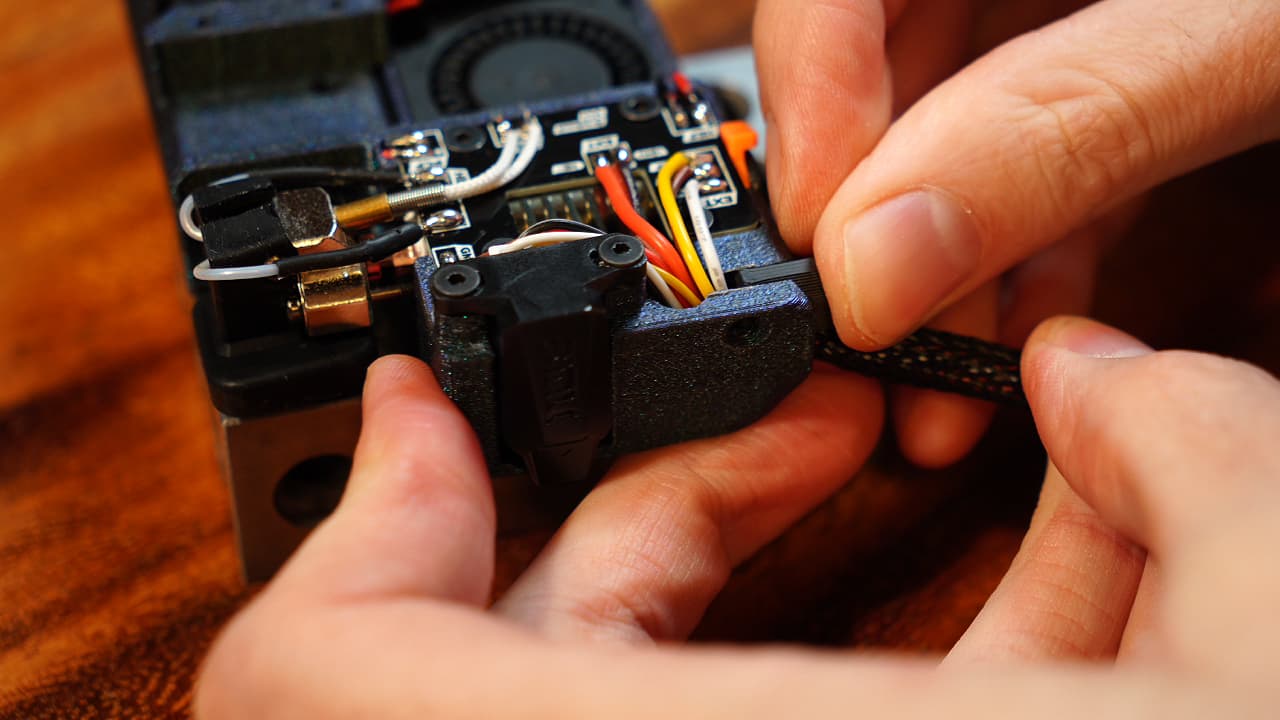

Gather parts for the tool

Tool body (printed), hotend, small fan, big fan, probe, connectors, crimps, power wires (silicone), signal wires, M2.5 x 6mm screws, pcb.

Tool body (printed), hotend, small fan, big fan, probe, connectors, crimps, power wires (silicone), signal wires, M2.5 x 6mm screws, pcb. -

Tighten the heat break

The heat break is loose from the factory. You need to rebuild the hotend.

The heat break is loose from the factory. You need to rebuild the hotend. -

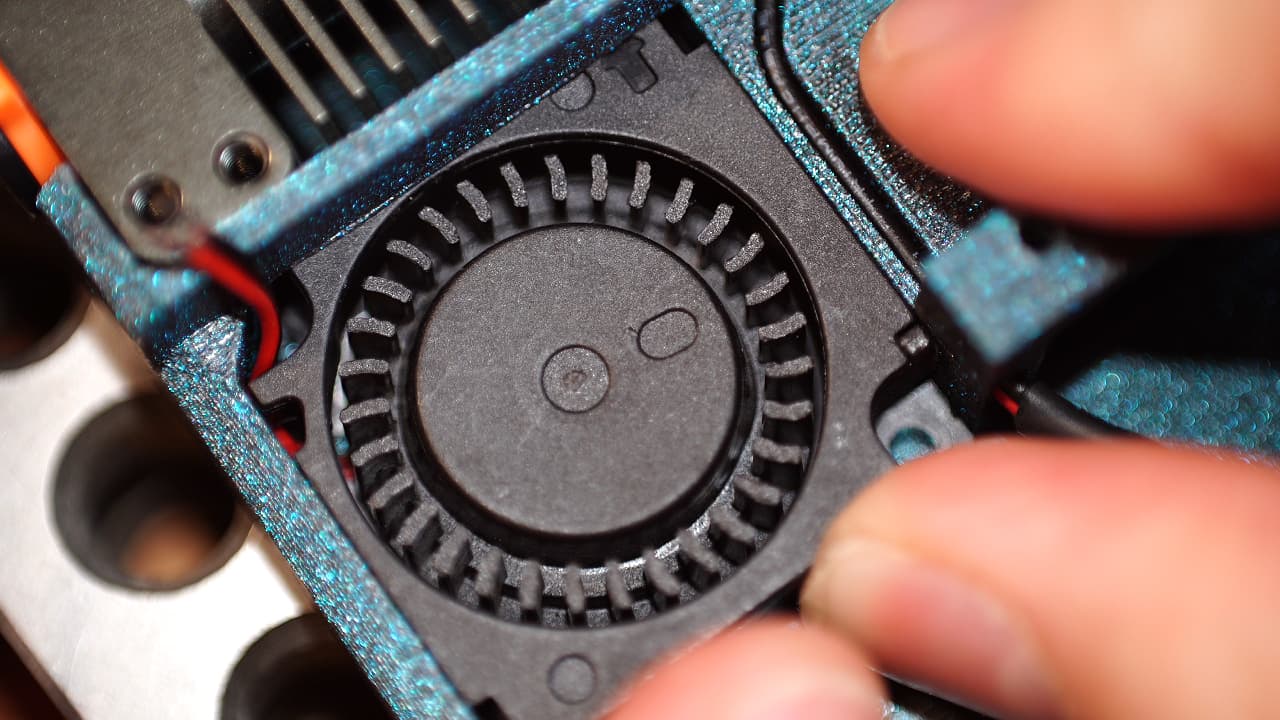

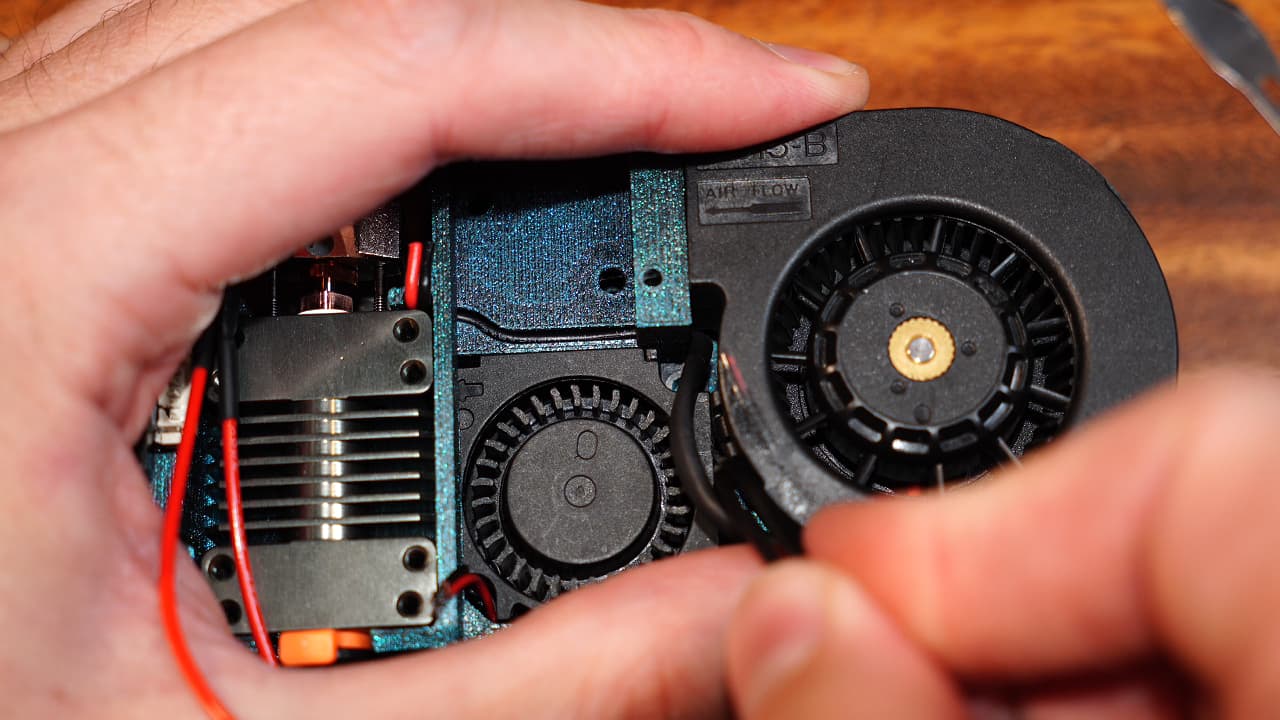

Modify the part cooling fan

Completely remove the two mounting tabs and wire retaining clip.

Completely remove the two mounting tabs and wire retaining clip. -

Push the wires through

Push the part cooling fan wires through the cavity of the tool head.

Push the part cooling fan wires through the cavity of the tool head. -

Drop in the hotend

The hotend will smoosh the wires and keep them in place. Now is a good time to strip the wires.

The hotend will smoosh the wires and keep them in place. Now is a good time to strip the wires. -

Fasten the hotend

Fasten the hotend to the tool body.M2.56mm

Fasten the hotend to the tool body.M2.56mm -

Fasten the probe

Fasten the probe to the tool body.M2.56mm

Fasten the probe to the tool body.M2.56mm -

Insert small fan

Insert the small fan and push it under the ledge so that it's touching the head sink.

Insert the small fan and push it under the ledge so that it's touching the head sink. -

Drop in the part cooling fan

Finish dropping in the cooling fan to lock everything in place.

Finish dropping in the cooling fan to lock everything in place. -

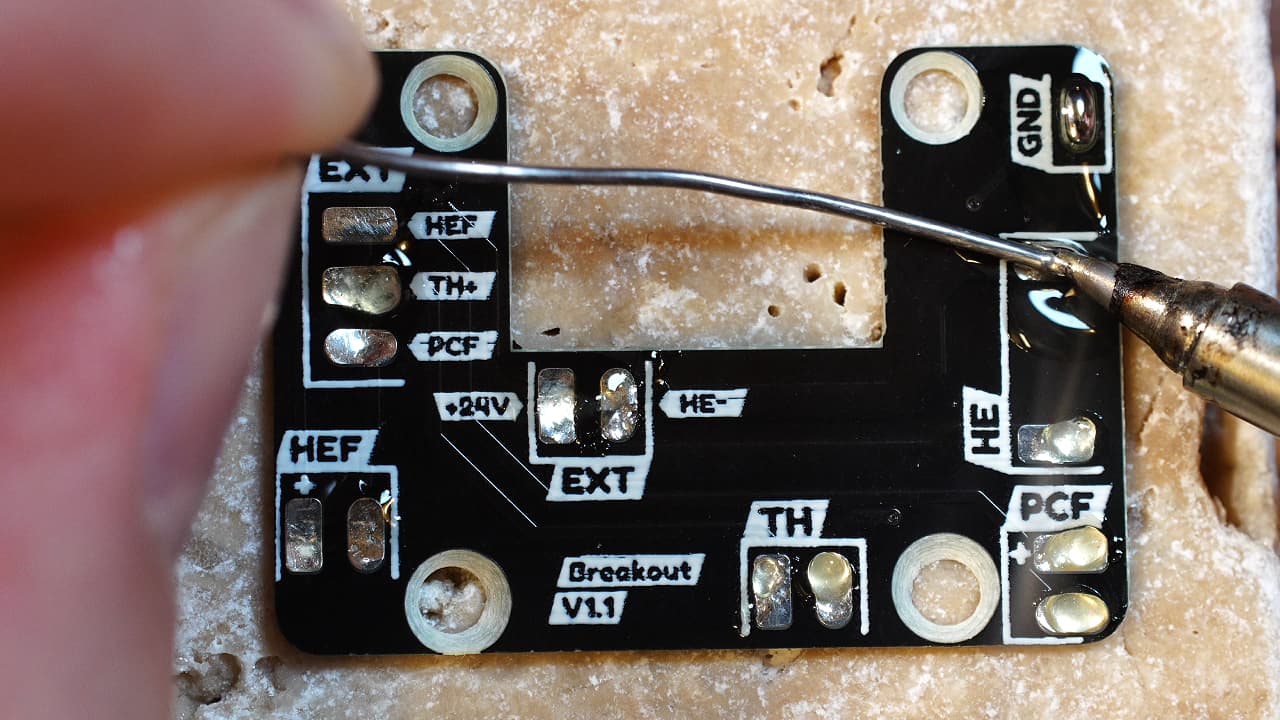

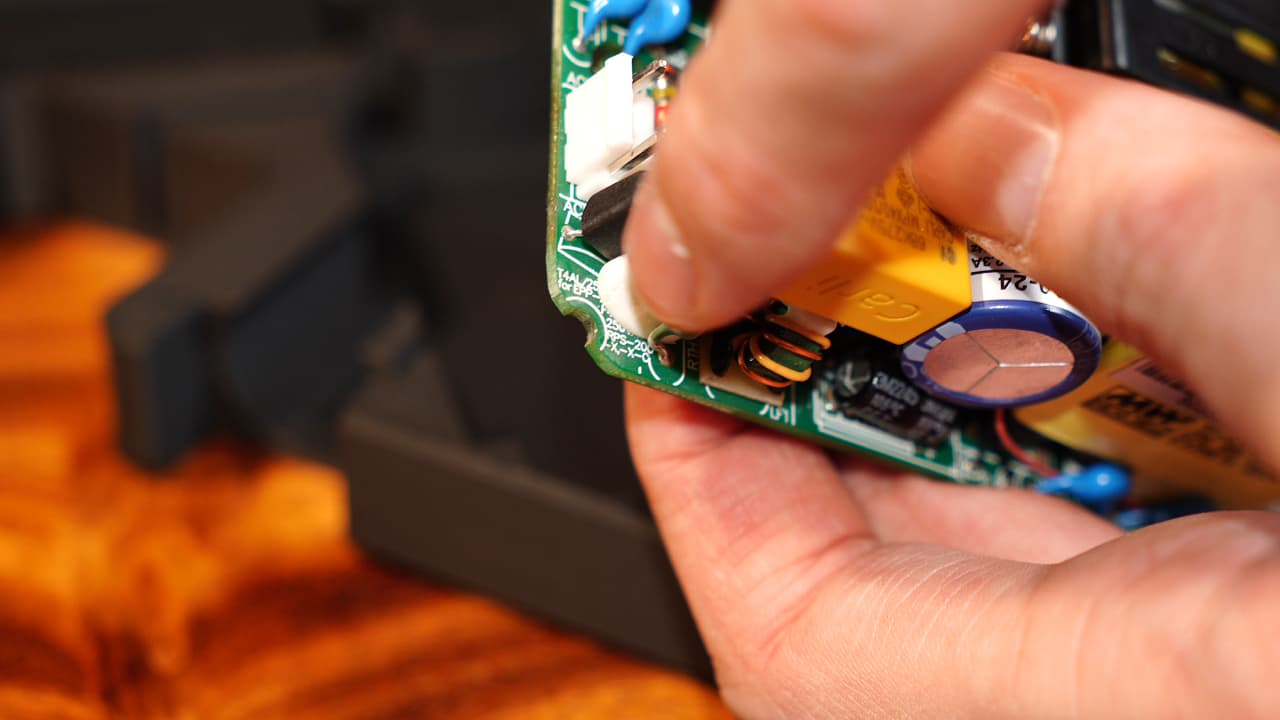

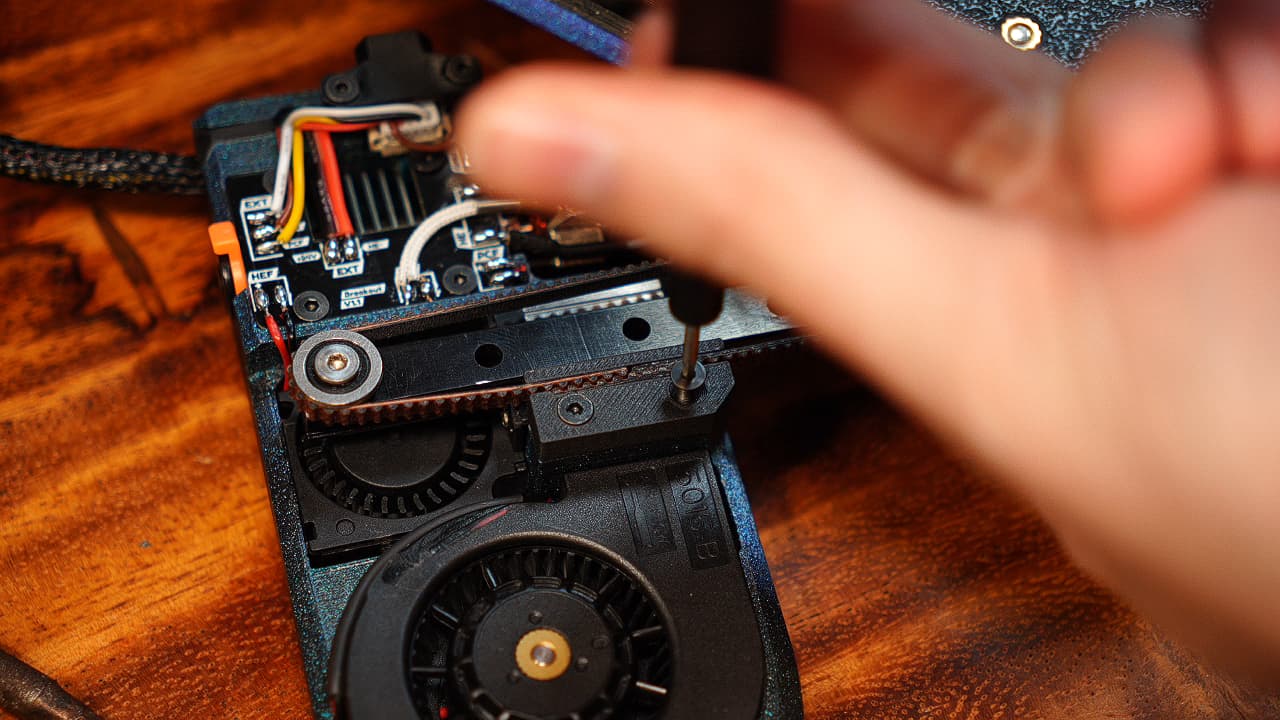

Tin the pcb

Apple some solder to hasten the wire bonding.

Apple some solder to hasten the wire bonding. -

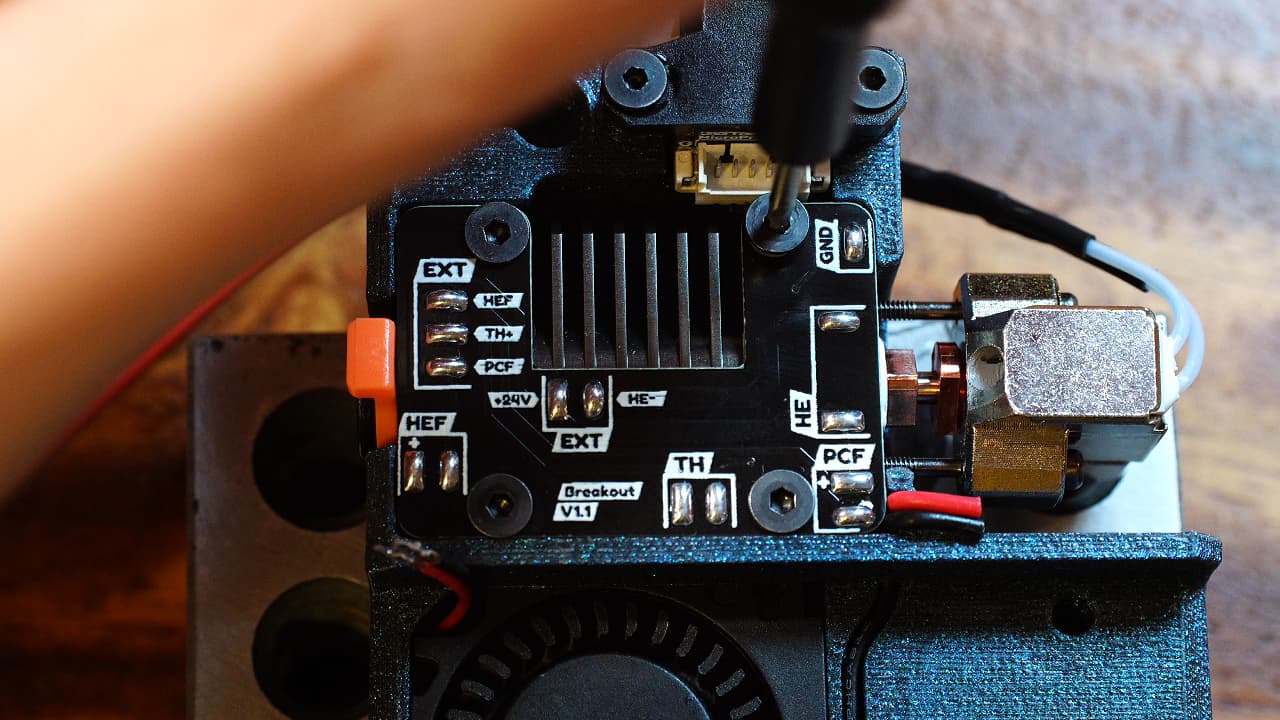

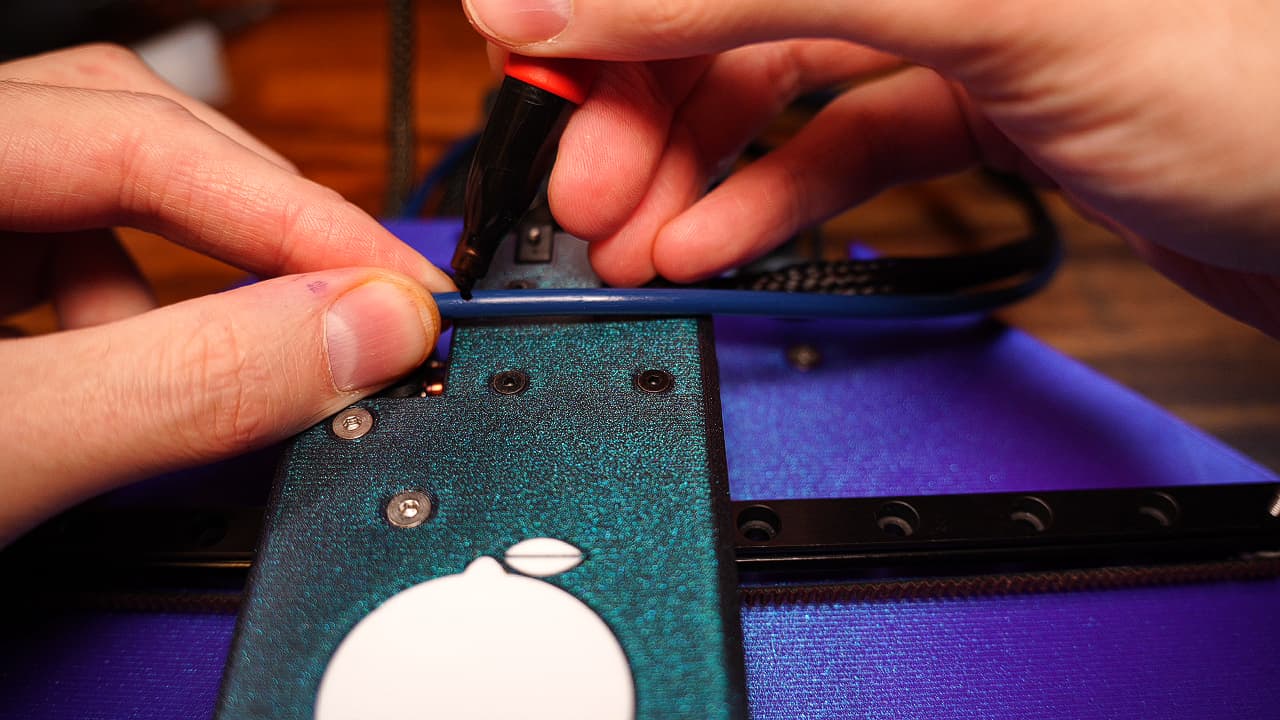

Fasten the pcb

Fasten the pcb to the heat sink.M2.56mm

Fasten the pcb to the heat sink.M2.56mm -

Solder the hotend fan

Solder the hotend fan (small fan) to the pads on the pcb.

Solder the hotend fan (small fan) to the pads on the pcb. -

Solder the part cooling fan

Solder the part cooling fan (big fan) to the pads on the pcb.

Solder the part cooling fan (big fan) to the pads on the pcb. -

Solder the heater

Clip and strip the wires at the end of the heat shrink tube. Solder to the pads on the pcb.

Clip and strip the wires at the end of the heat shrink tube. Solder to the pads on the pcb. -

Shorten the thermistor spring

Clip the spring in half.

Clip the spring in half. -

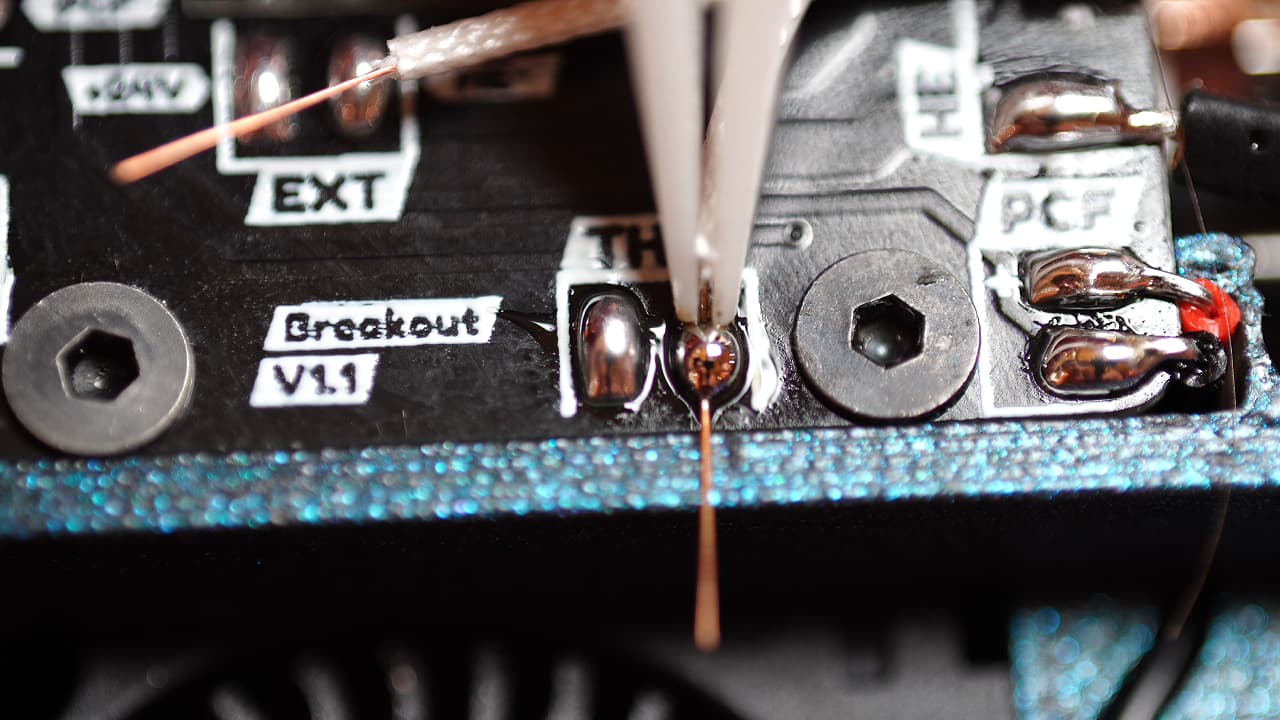

Solder the thermistor

Clip and strip the wires and solder them to the pads on the pcb.

Clip and strip the wires and solder them to the pads on the pcb. -

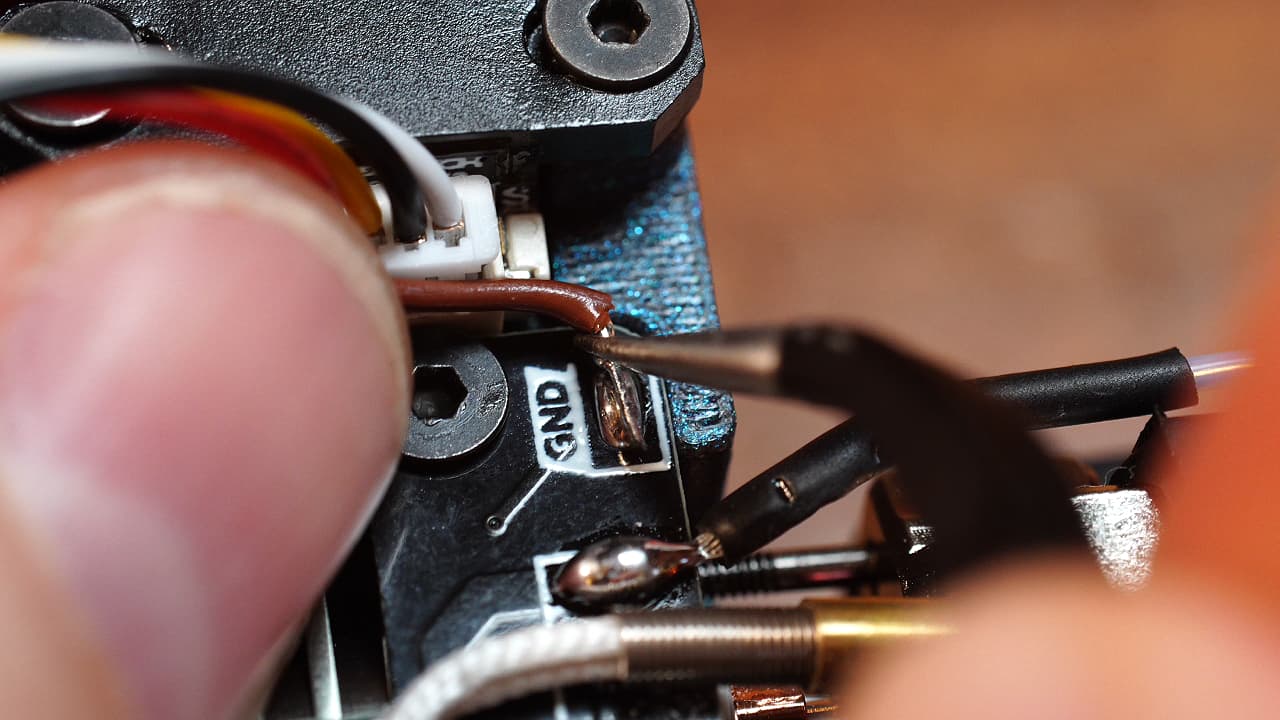

Plug in & solder the probe

Plug in the probe and split off one of the grounds (black or brown) and solder it to the pad. You can reuse this wire so don't throw it away.

Plug in the probe and split off one of the grounds (black or brown) and solder it to the pad. You can reuse this wire so don't throw it away. -

Solder the heater wire

Solder the heater wire. Don't solder it as pictured. The pcb is literally labelled, I don't know why I flipped it but I did. I will replace this picture later.

Solder the heater wire. Don't solder it as pictured. The pcb is literally labelled, I don't know why I flipped it but I did. I will replace this picture later. -

Solder the thermistor wire

Using the leftover wire from the probe, solder the thermistor signal wire.

Using the leftover wire from the probe, solder the thermistor signal wire. -

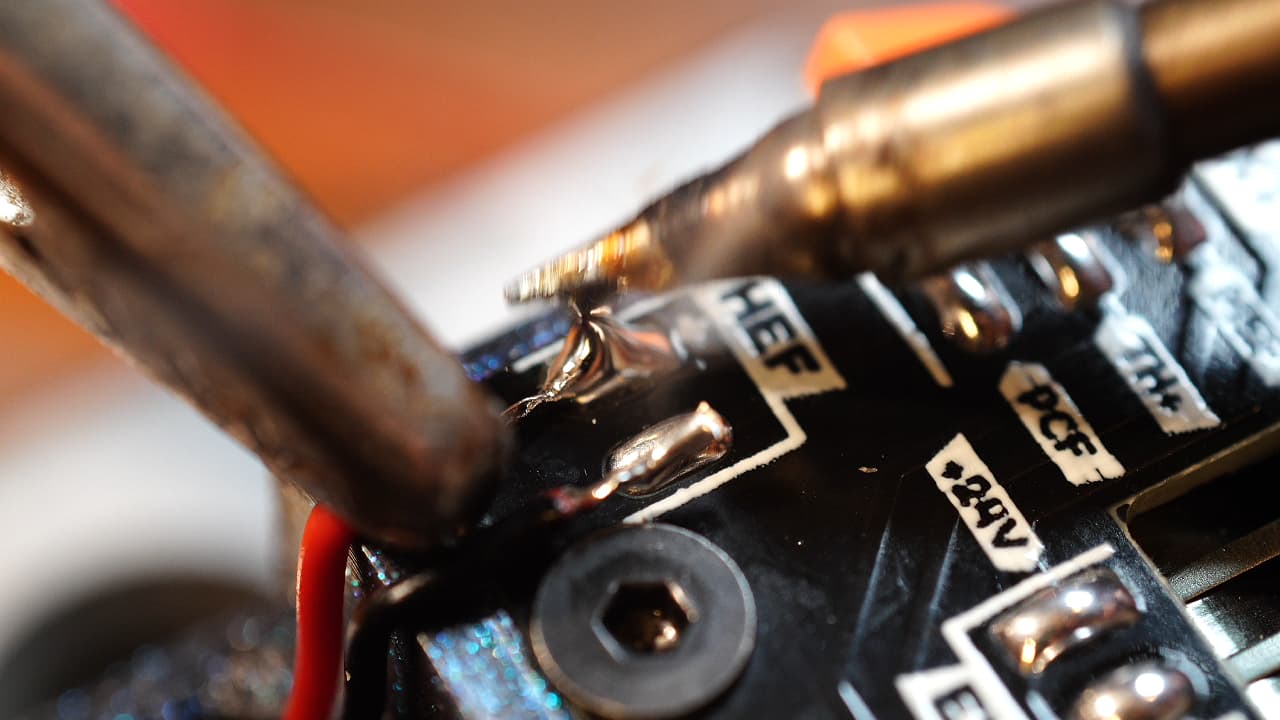

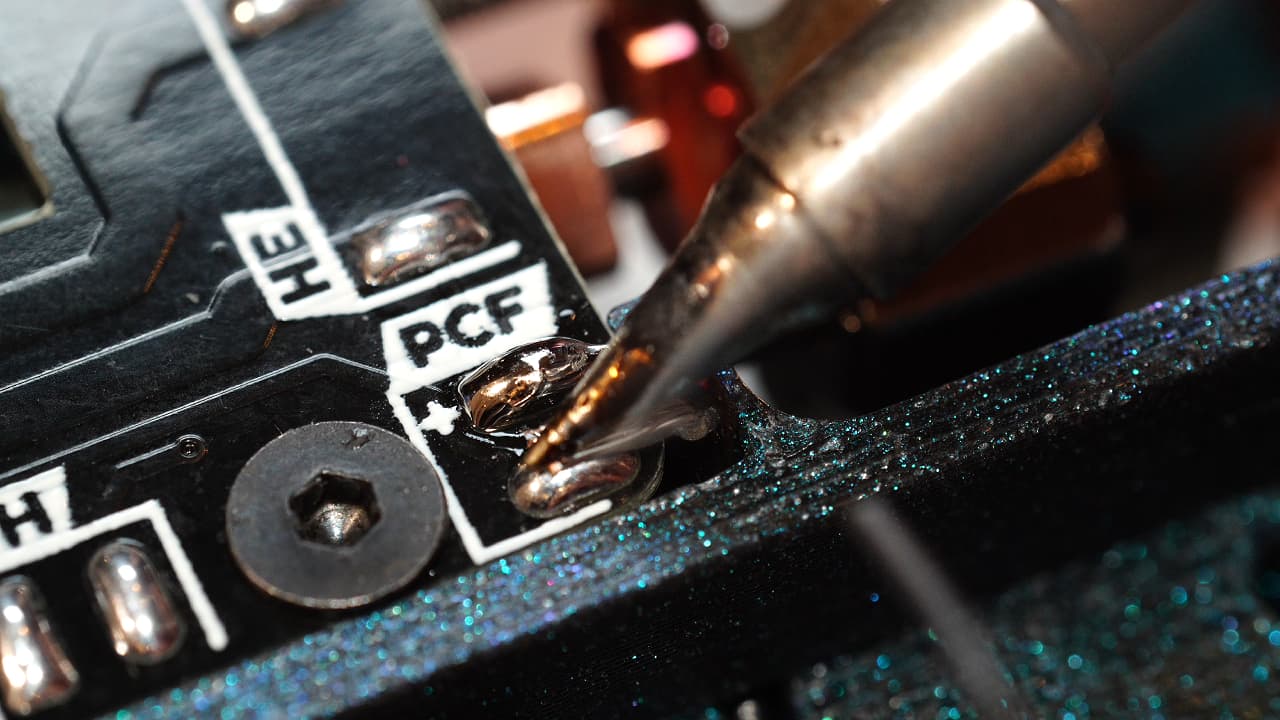

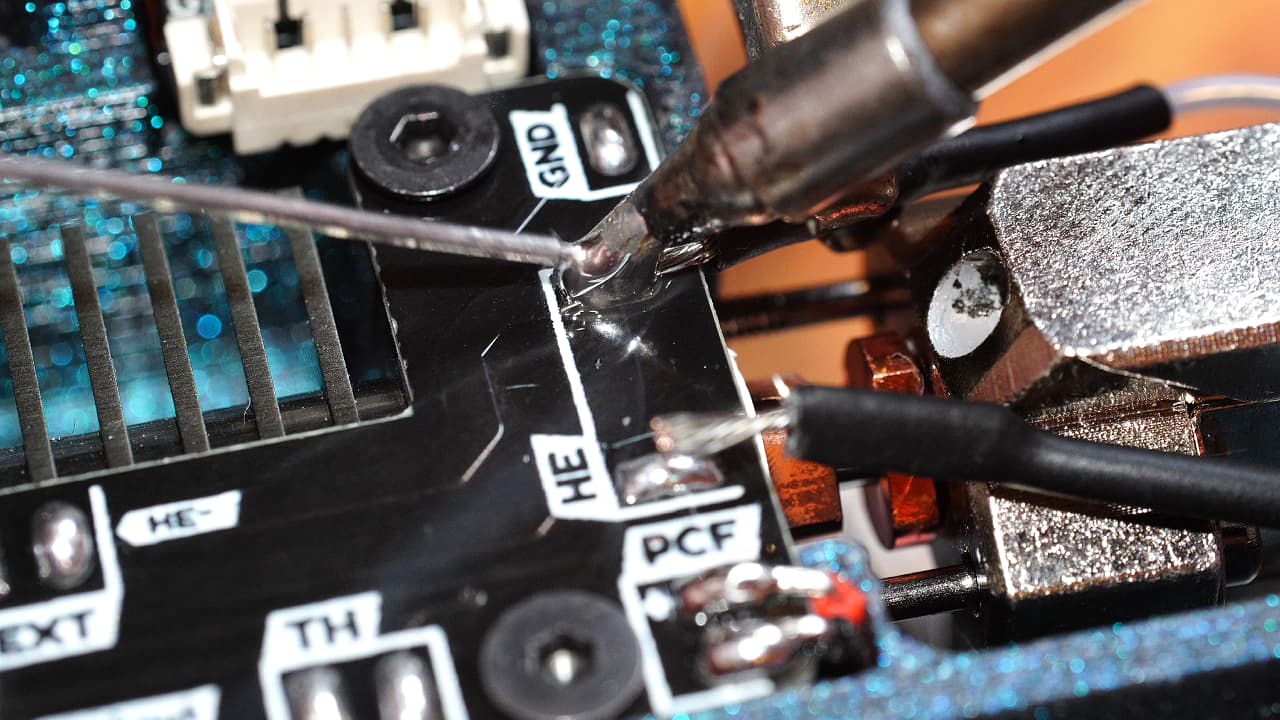

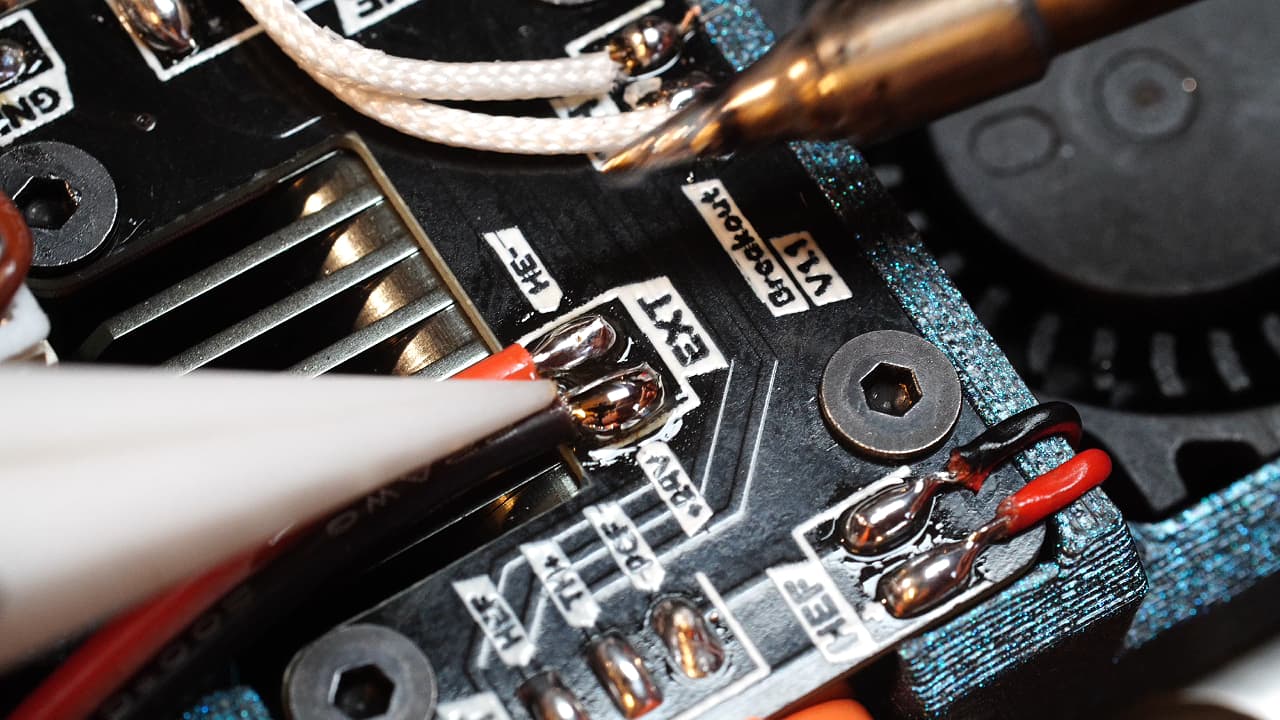

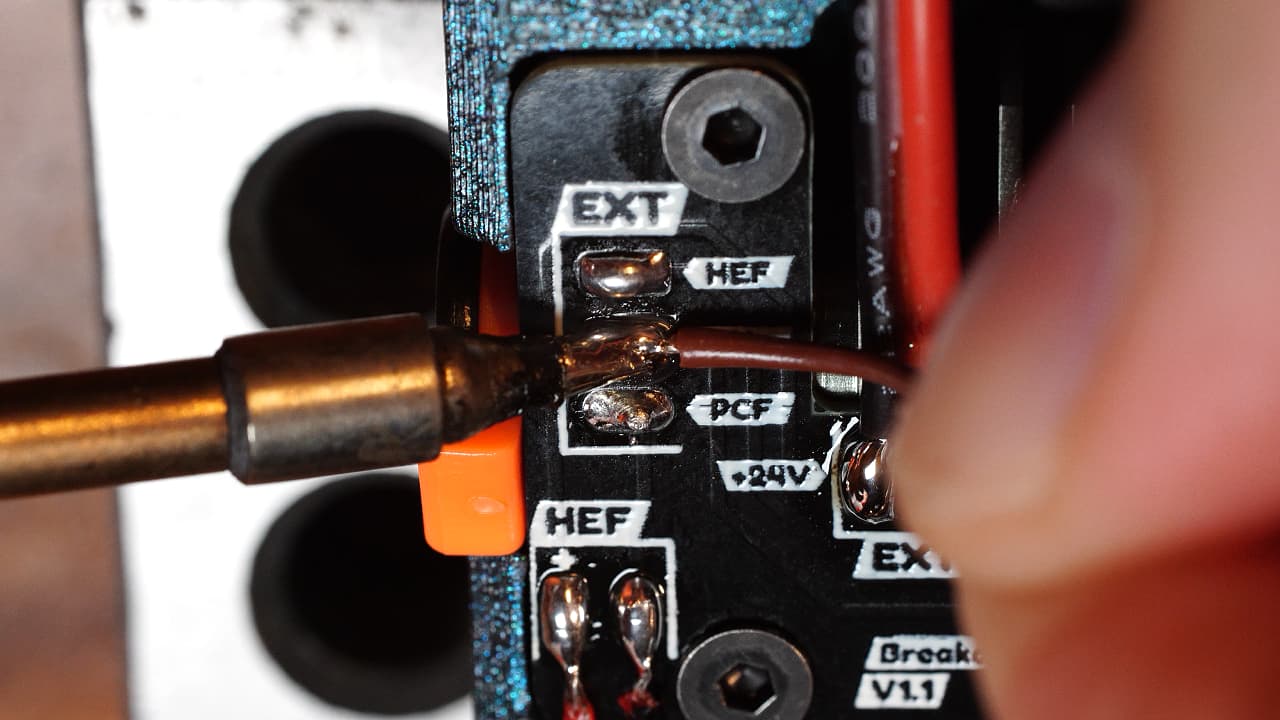

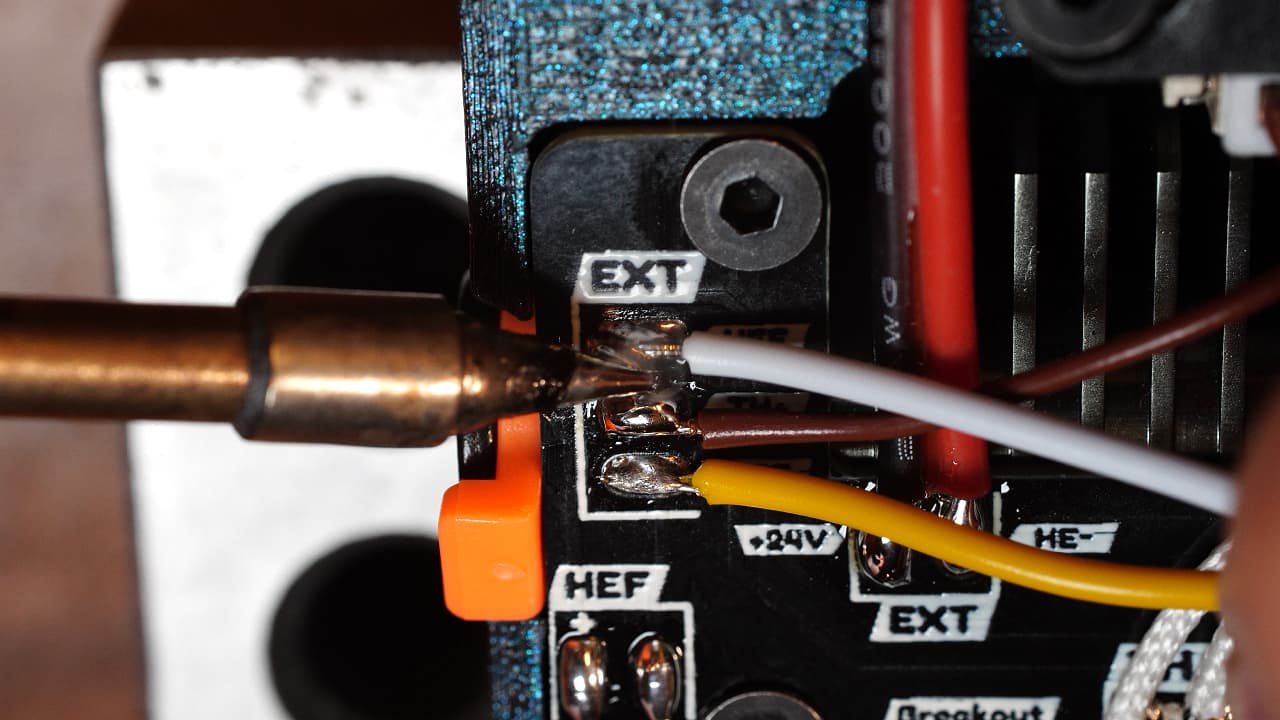

Solder the fan wires

Cut two wires roughly to 50cm and solder them to the two fan pads on the pcb.On the pcb, the silk screen has a mistake. The HEF and PCF labels are swapped. From top to bottom, the correct wiring is PCF, TH+ and HEF.

Cut two wires roughly to 50cm and solder them to the two fan pads on the pcb.On the pcb, the silk screen has a mistake. The HEF and PCF labels are swapped. From top to bottom, the correct wiring is PCF, TH+ and HEF. -

Wrap the wires

Use 47cm of wire sleeve to wrap the wires.

Use 47cm of wire sleeve to wrap the wires. -

Insert the clamp

Clamp down the wires by pushing in the clamp and securing it with a screw.M312mm

Clamp down the wires by pushing in the clamp and securing it with a screw.M312mm -

Clip the tool wires

Cut the heater wire and probe wires to 53cm, the rest to 55cm.

Cut the heater wire and probe wires to 53cm, the rest to 55cm. -

Tin the heater wires

Trim back 5mm off the heater wires and tin the ends.

Trim back 5mm off the heater wires and tin the ends. -

Crimp the thermistor wire

Crimp the thermistor wire and insert it into the connector side without the marking.

Crimp the thermistor wire and insert it into the connector side without the marking. -

Crimp the hotend fan wire

Crimp the hotend fan wire and insert it into the connector side without the marking.

Crimp the hotend fan wire and insert it into the connector side without the marking. -

Crimp the part cooling fan wire

Crimp the part cooling fan wire and insert it into the connector side without the marking.

Crimp the part cooling fan wire and insert it into the connector side without the marking. -

Crimp the probe sensor wires

Crimp the probe sensor wires and insert them into position 2 & 3 as shown.

Crimp the probe sensor wires and insert them into position 2 & 3 as shown. -

Crimp the probe servo wires

Crimp the probe servo wires and insert them as shown; black on the marking, white on the other position.

Crimp the probe servo wires and insert them as shown; black on the marking, white on the other position. -

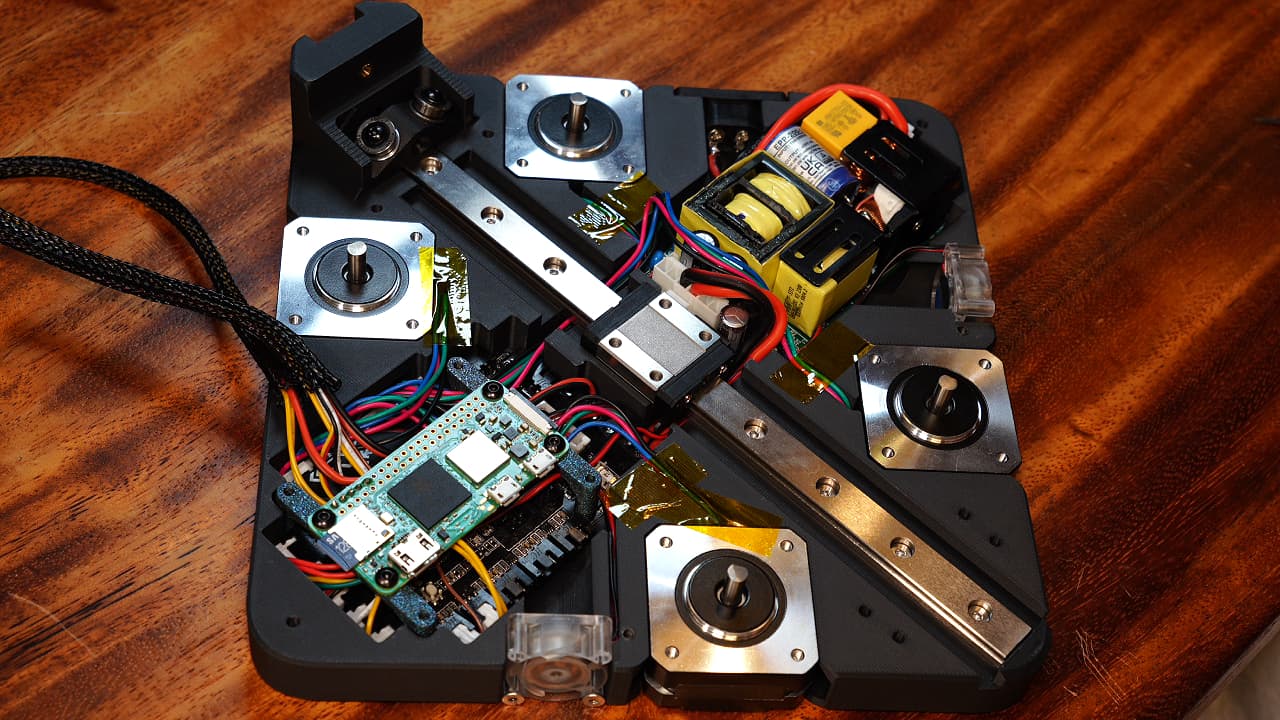

Gather the chassis parts

This is the rest of the parts! Draw the rest of the horse!

This is the rest of the parts! Draw the rest of the horse! -

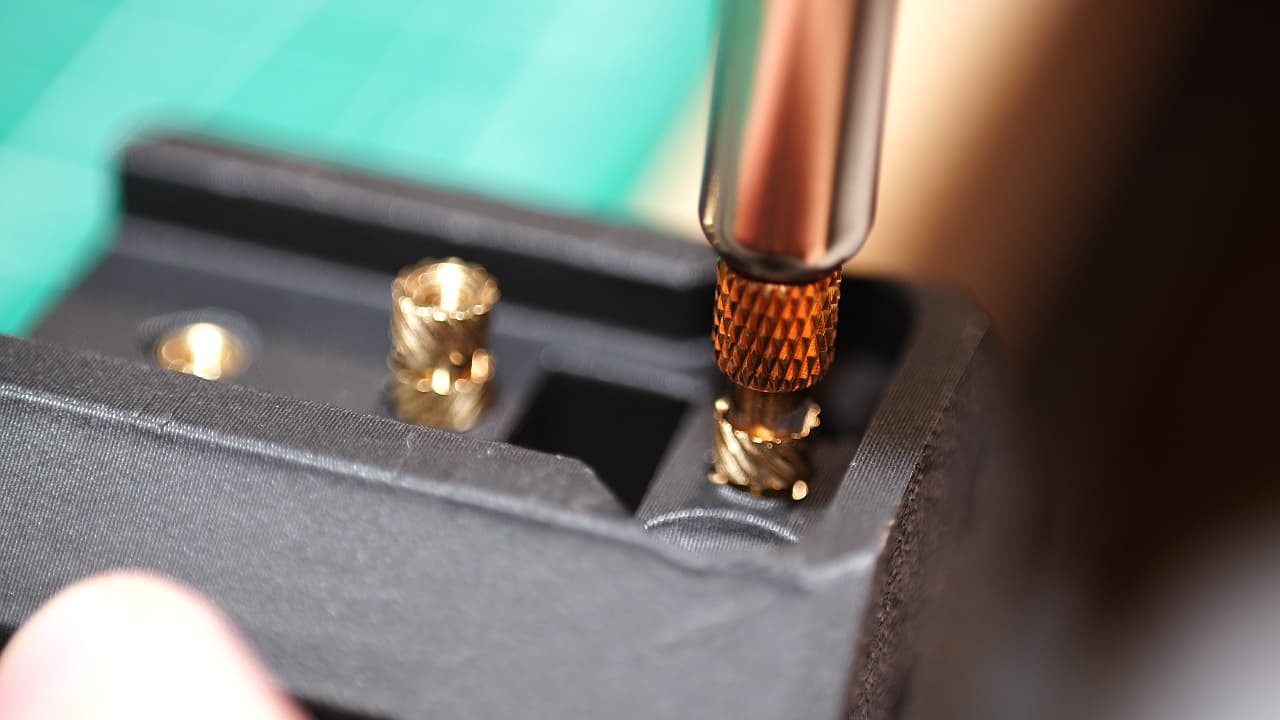

Insert the heat set inserts

Press in the 4 top inserts and 2 bottom inserts. These 10mm long threaded inserts are super strong. After pushing in the inserts, press down on the surface with a flat piece of metal to cool and ensure flatness.

Press in the 4 top inserts and 2 bottom inserts. These 10mm long threaded inserts are super strong. After pushing in the inserts, press down on the surface with a flat piece of metal to cool and ensure flatness. -

Insert the top z-block insert

Insert the top z-block insert from the front.

Insert the top z-block insert from the front. -

Insert the bottom z-block inserts

Insert the bottom two z-block inserts from the rear.

Insert the bottom two z-block inserts from the rear. -

Insert the vertical chassis stiffeners

O P T I O N A L Optionally add the two M4 45mm stiffeners.

Optionally add the two M4 45mm stiffeners. -

Insert the horizontal chassis stiffeners

O P T I O N A L Optionally add the two M5 80mm stiffeners.

Optionally add the two M5 80mm stiffeners. -

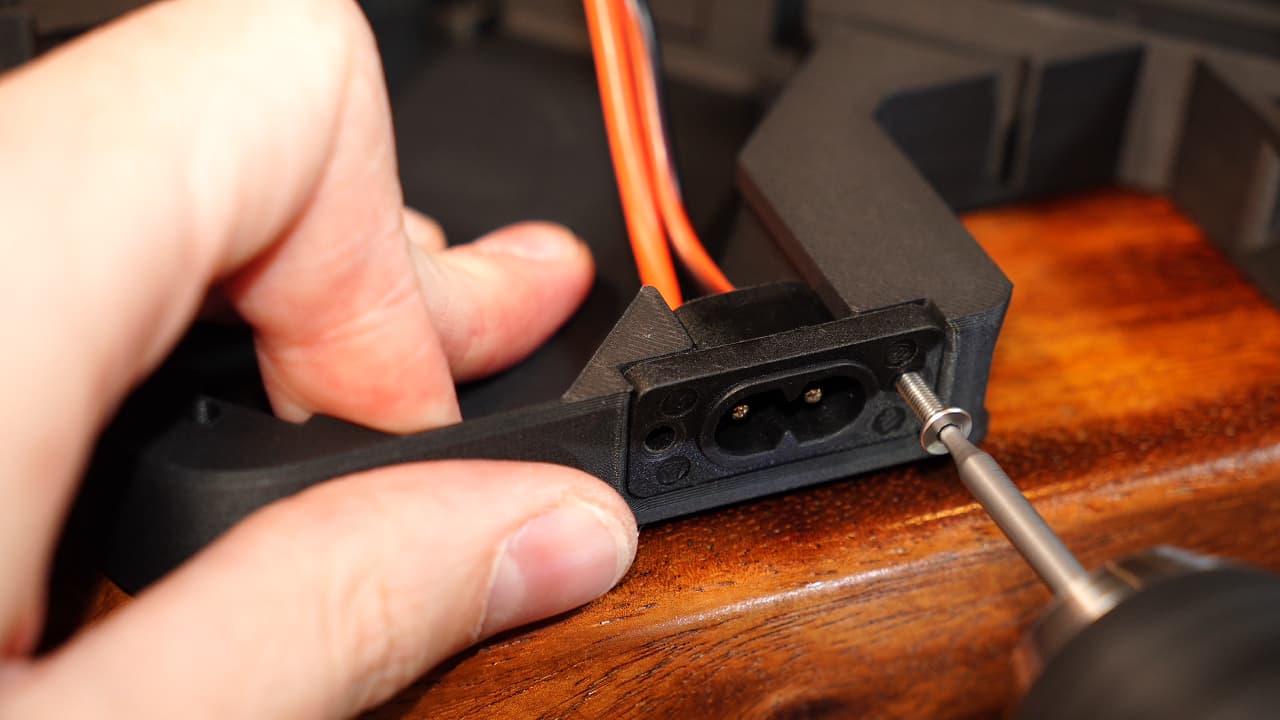

Insert the AC input jack

Slide in the AC jack and fasten with two screws.M314mm

Slide in the AC jack and fasten with two screws.M314mm -

Modify PSU

Bevel the two corners of the PSU that face outwards. The cut should bisect the screw post holes.

Bevel the two corners of the PSU that face outwards. The cut should bisect the screw post holes. -

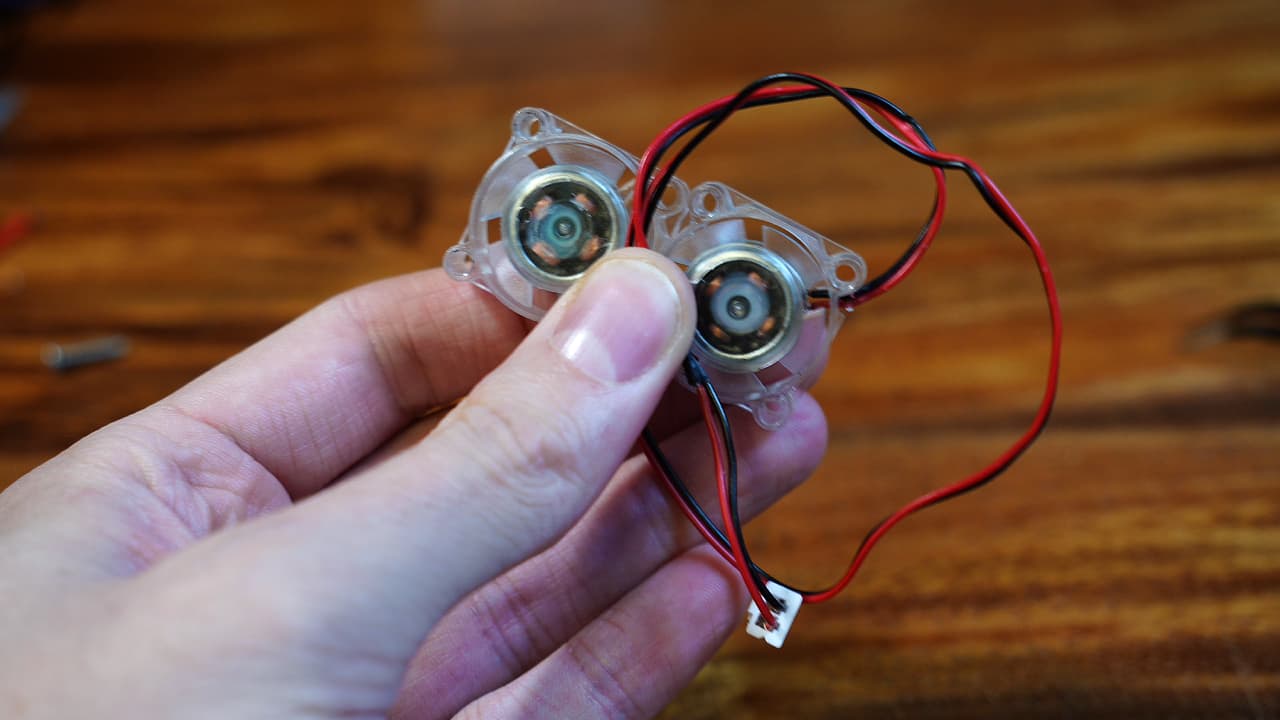

Link the fans together

Wire two chassis fans in parallel so that the wire is long enough to reach the ports on the left of the MCU.

Wire two chassis fans in parallel so that the wire is long enough to reach the ports on the left of the MCU. -

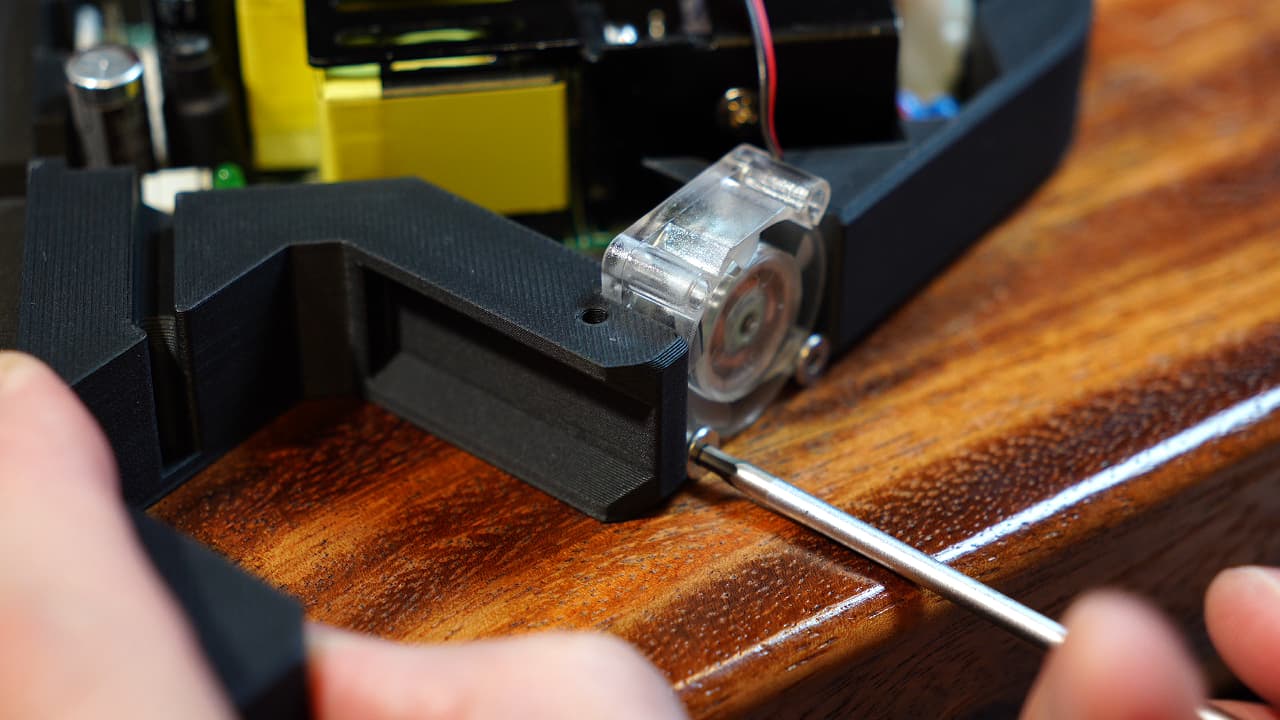

Insert the right fan

Insert the fan and secure the bottom two screw holes.M314mm

Insert the fan and secure the bottom two screw holes.M314mm -

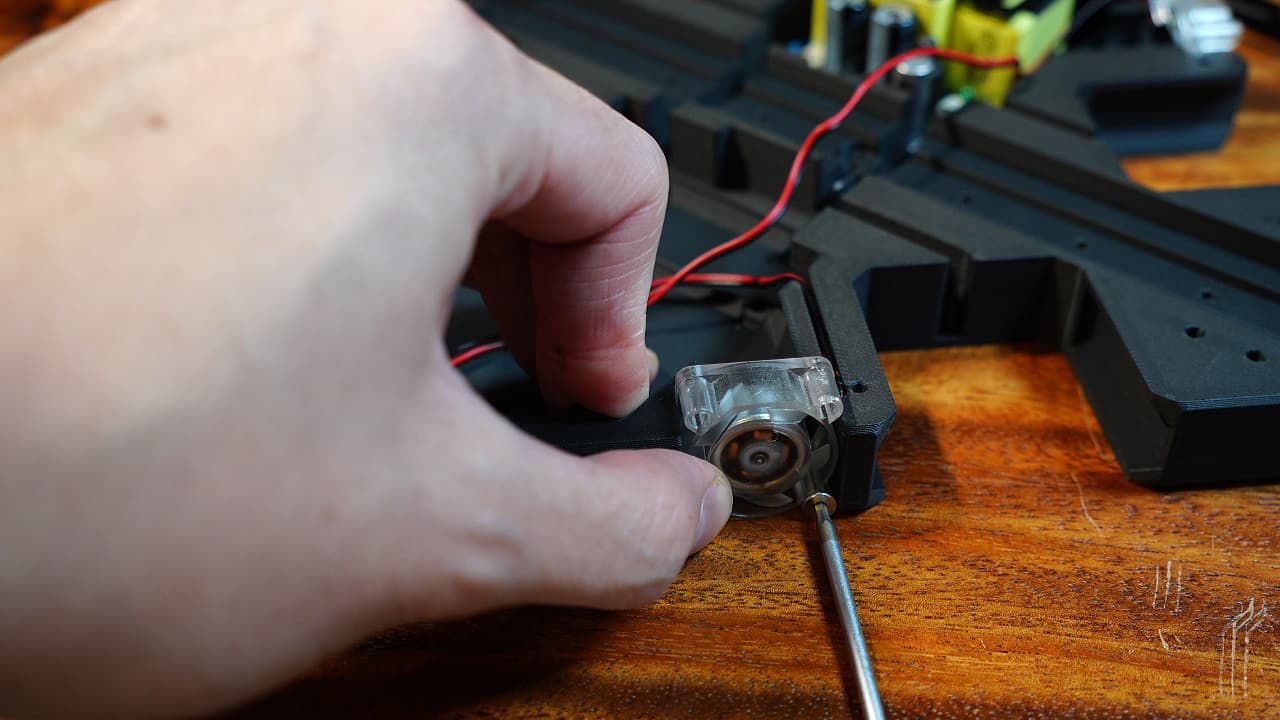

Insert the left fan

Insert the fan and secure the bottom two screw holes.M314mm

Insert the fan and secure the bottom two screw holes.M314mm -

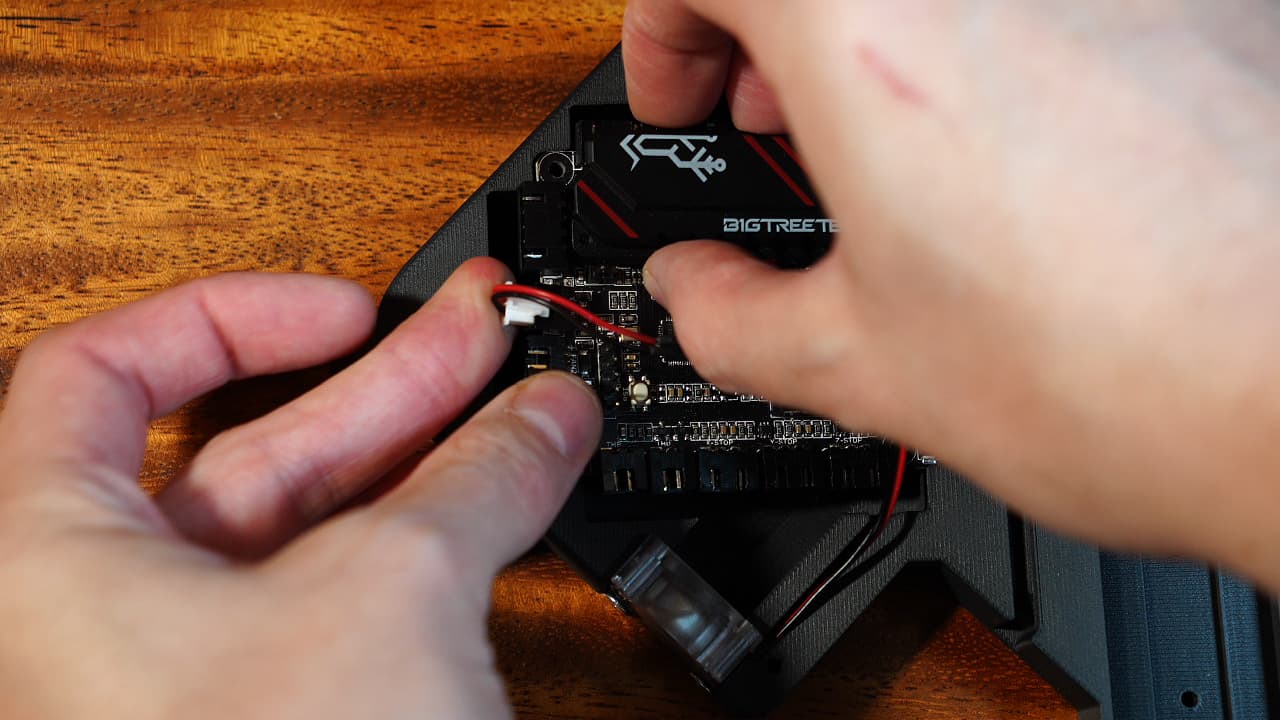

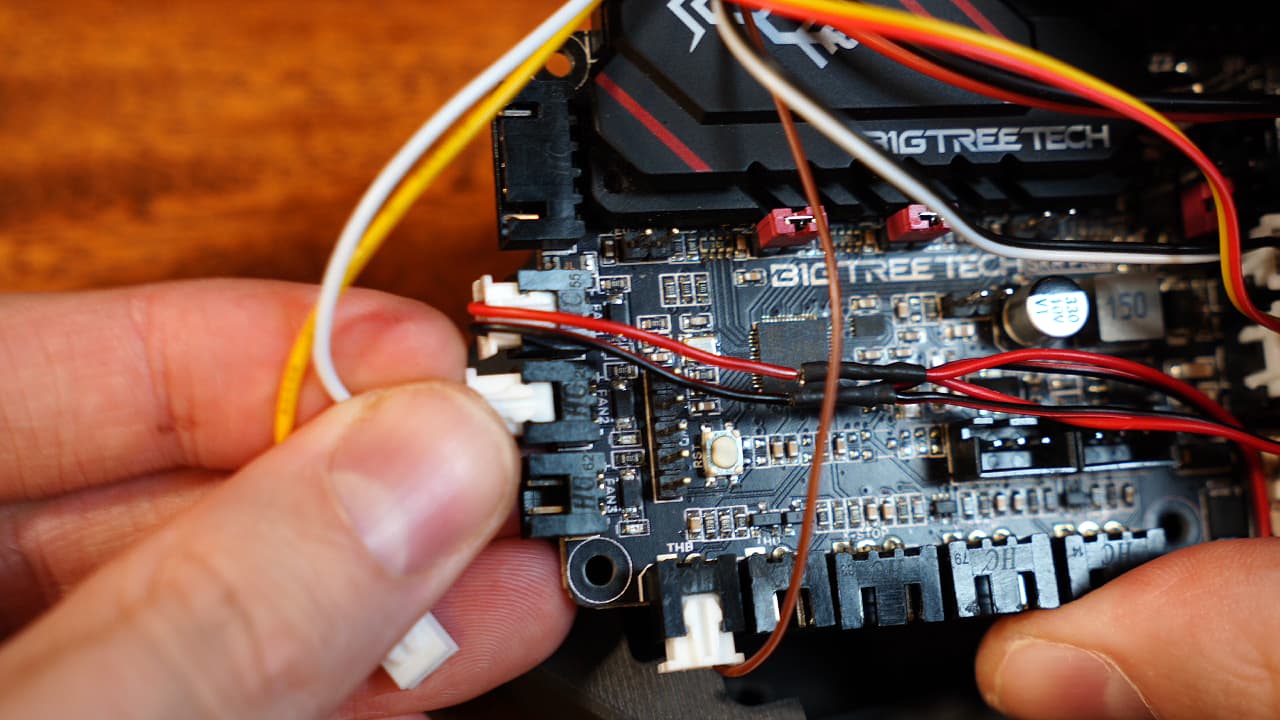

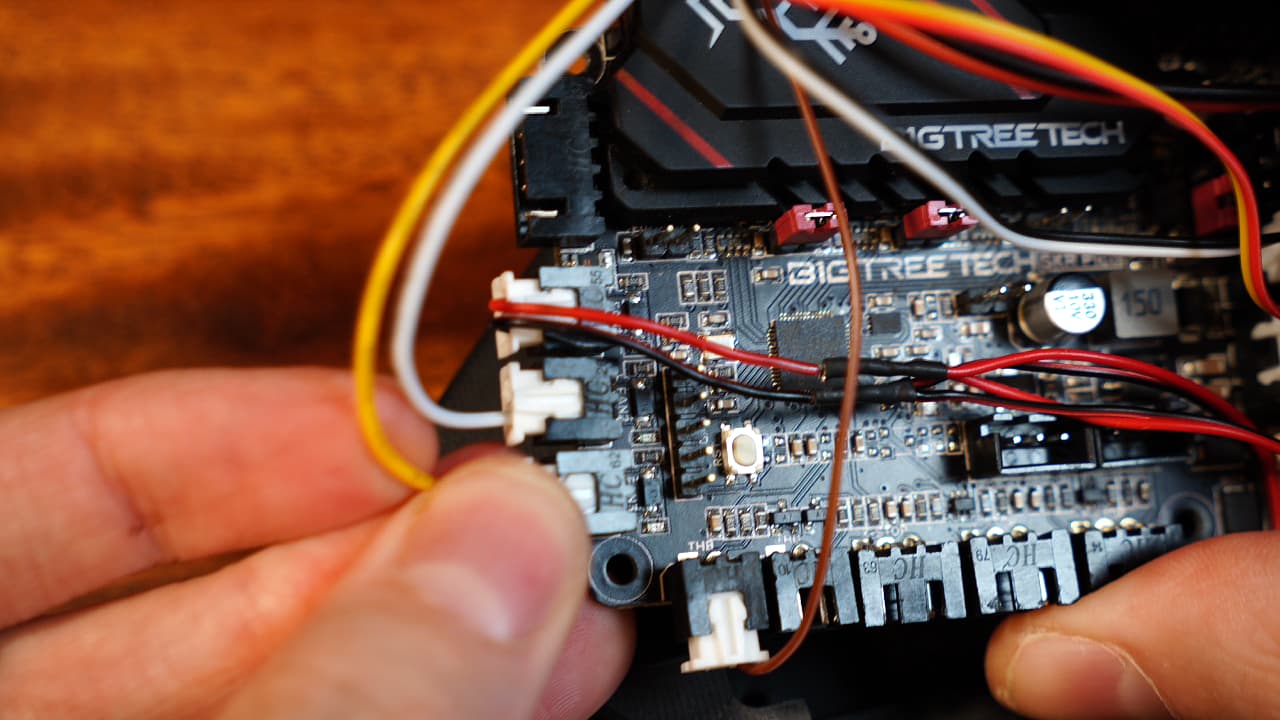

Plug in the fans

Plug in the chassis fans to the top port of the MCU.

Plug in the chassis fans to the top port of the MCU. -

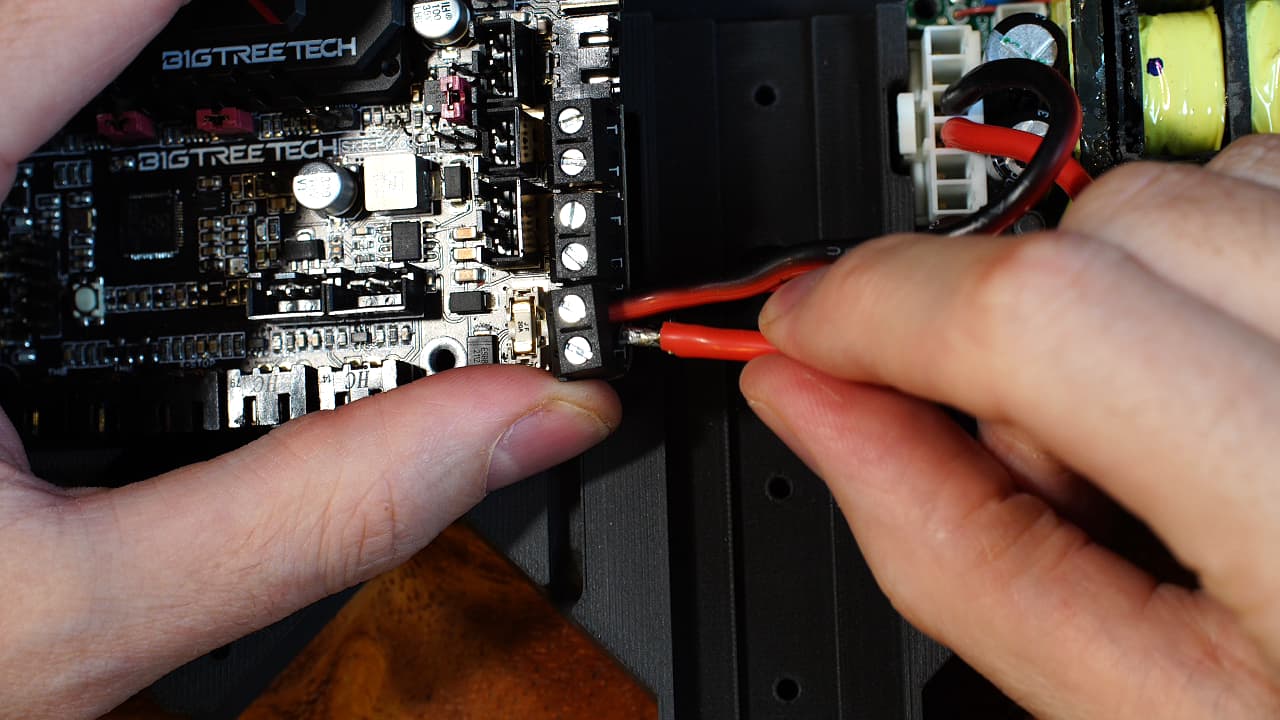

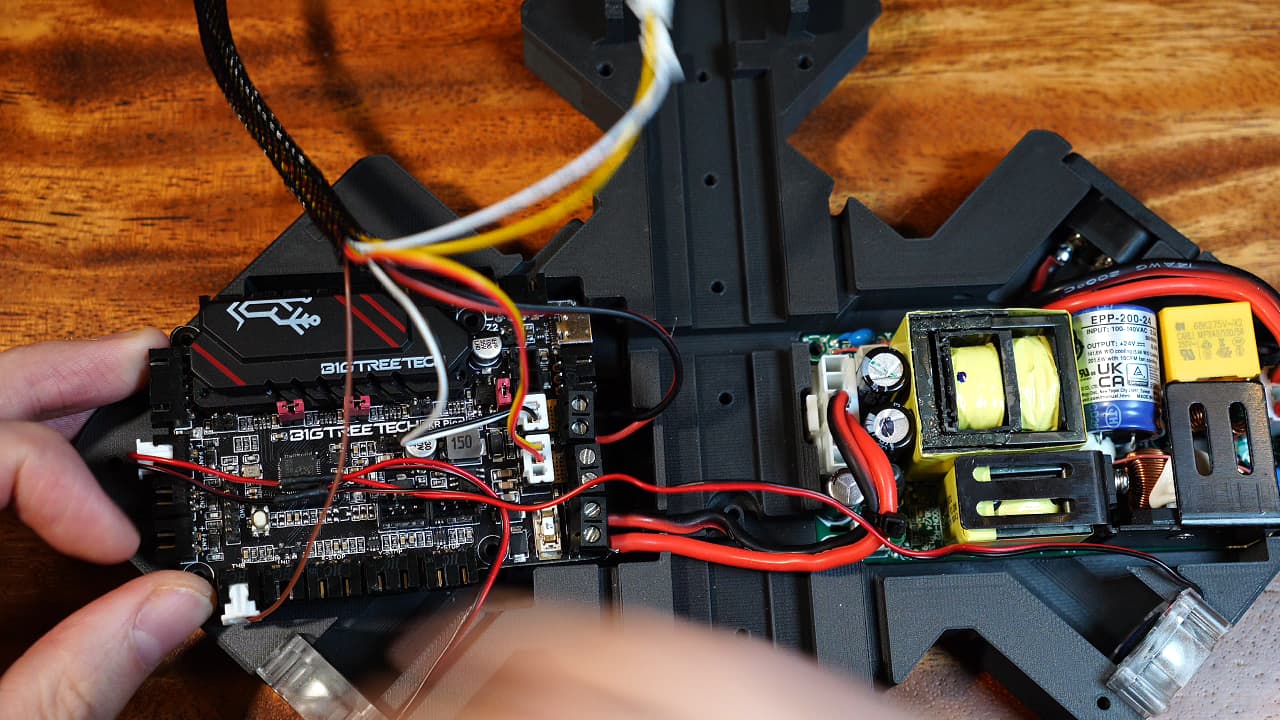

Plug in the power wires

Connect the power wires to the PSU and cut to length, tin the ends, and plug in. The gauge of these wires should be 18AWG or thicker. 14AWG is the largest wire the terminal blocks can accept.

Connect the power wires to the PSU and cut to length, tin the ends, and plug in. The gauge of these wires should be 18AWG or thicker. 14AWG is the largest wire the terminal blocks can accept. -

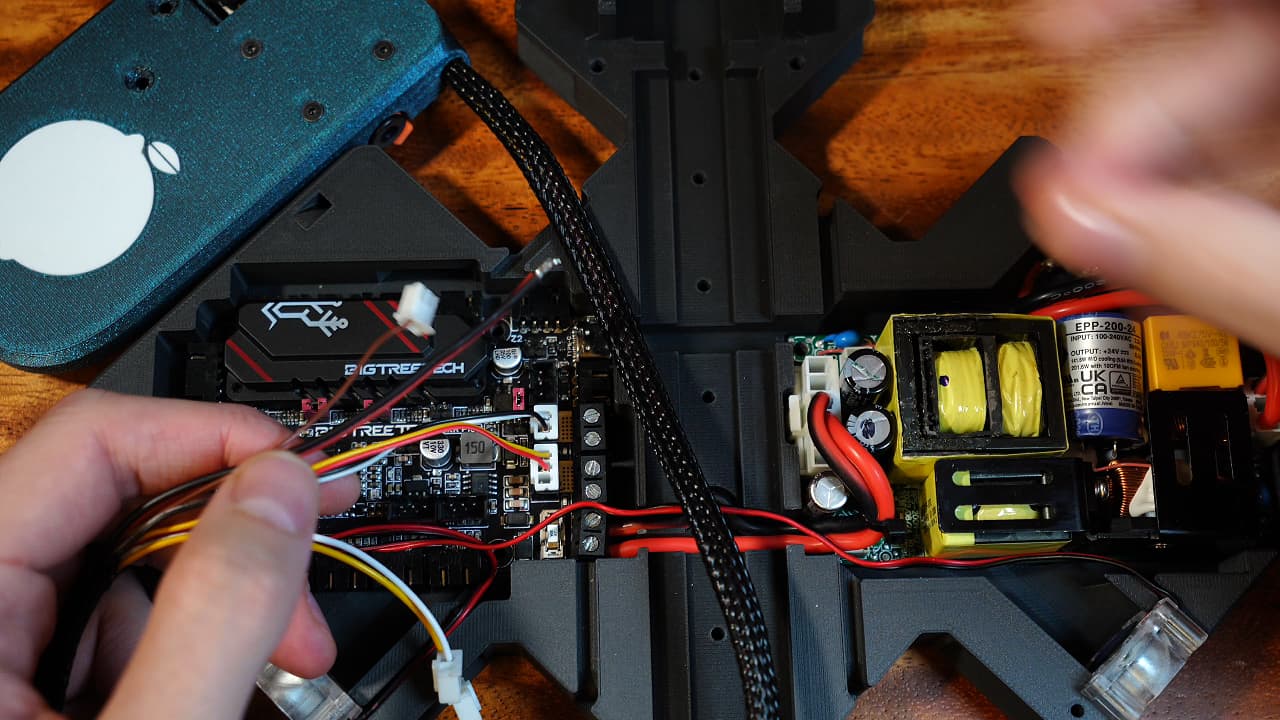

Plug in the probe connectors

Connect the two probe connectors as shown- B/W on top, Y/R on bottom.

Connect the two probe connectors as shown- B/W on top, Y/R on bottom. -

Plug in the hotend heater wires

Insert the two heater wires into the top terminal block.

Insert the two heater wires into the top terminal block. -

Plug in the hotend thermistor connector

Insert the thermistor wire into the bottom left port.

Insert the thermistor wire into the bottom left port. -

Plug in the hotend fan connector

Insert the hotend fan connector into the second port.

Insert the hotend fan connector into the second port. -

Plug in the part cooling fan connector

Insert the part cooling fan connector into the third port.

Insert the part cooling fan connector into the third port. -

Plug in the bed thermistor

Bring over the z-axis and insert the heat bed thermistor connector next to the hotend thermistor.

Bring over the z-axis and insert the heat bed thermistor connector next to the hotend thermistor. -

Plug in the bed heater

Insert the heat bed power wires into the middle terminal block and tighten.

Insert the heat bed power wires into the middle terminal block and tighten. -

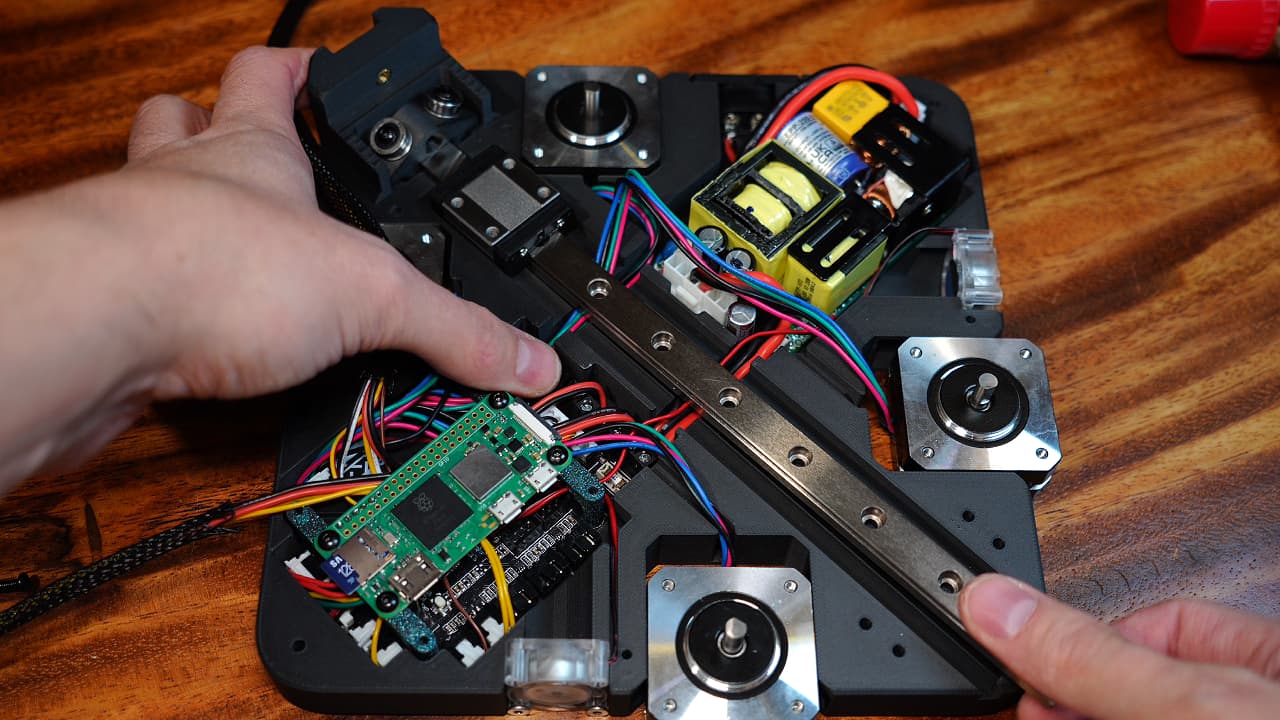

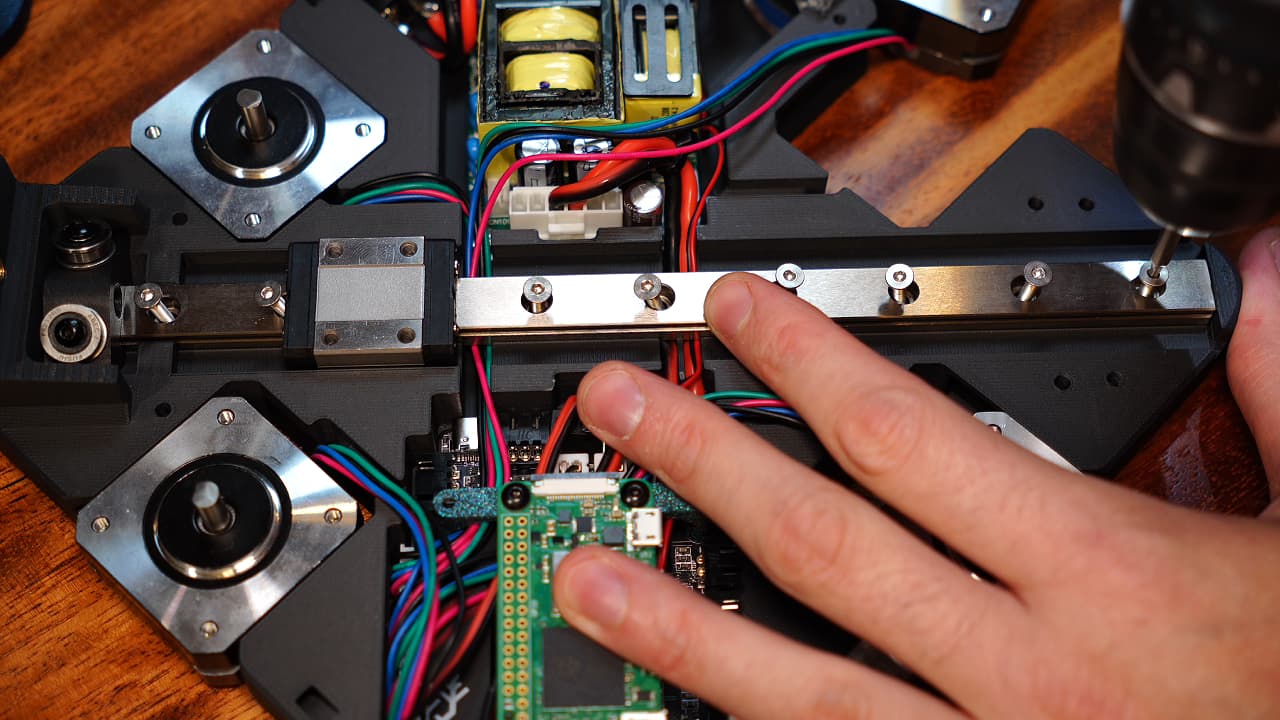

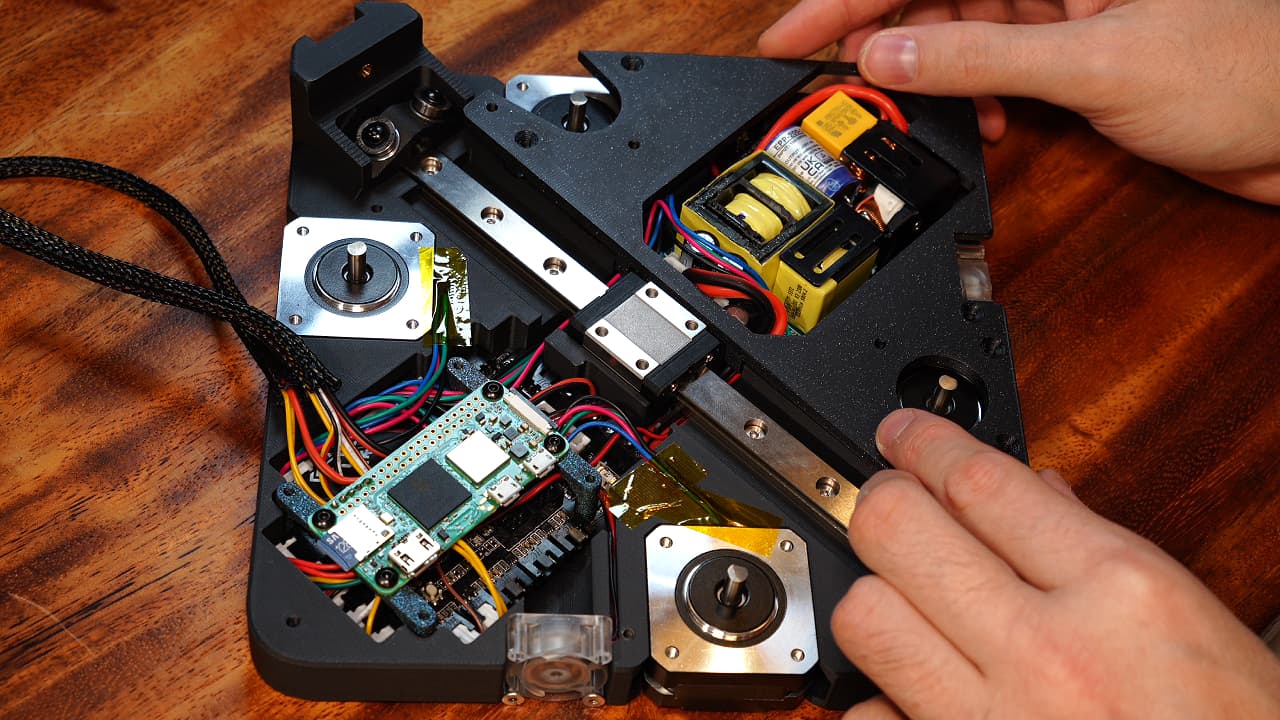

Insert the motors

Bottom left motor has 15cm wire, bottom right has 23cm wire, top right has 15cm wire, top left has 10cm wire.

Bottom left motor has 15cm wire, bottom right has 23cm wire, top right has 15cm wire, top left has 10cm wire. -

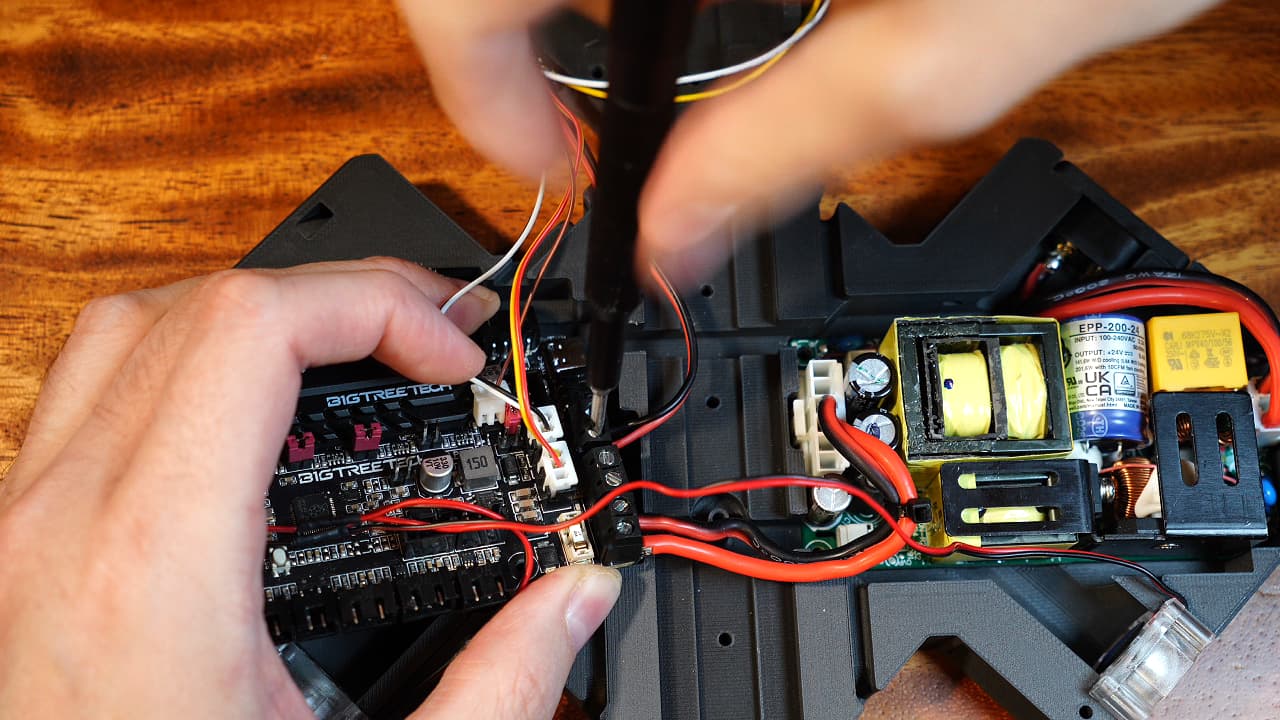

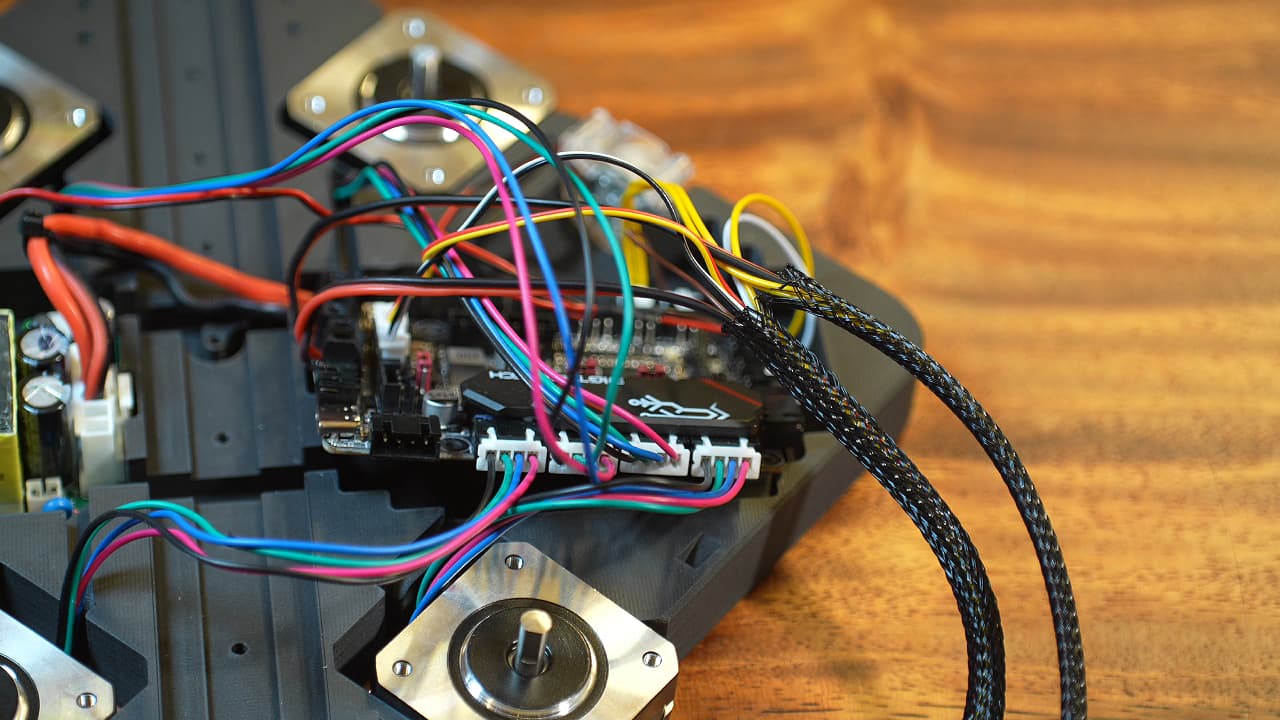

Plug in the motors

Referring to the SKR Pico pinout, port E connects to the top left (extruder) motor, port X to the bottom left (A) motor, port Y to the bottom right motor (B), port Z1 to the top right (Z-Axis) motor.

Referring to the SKR Pico pinout, port E connects to the top left (extruder) motor, port X to the bottom left (A) motor, port Y to the bottom right motor (B), port Z1 to the top right (Z-Axis) motor. -

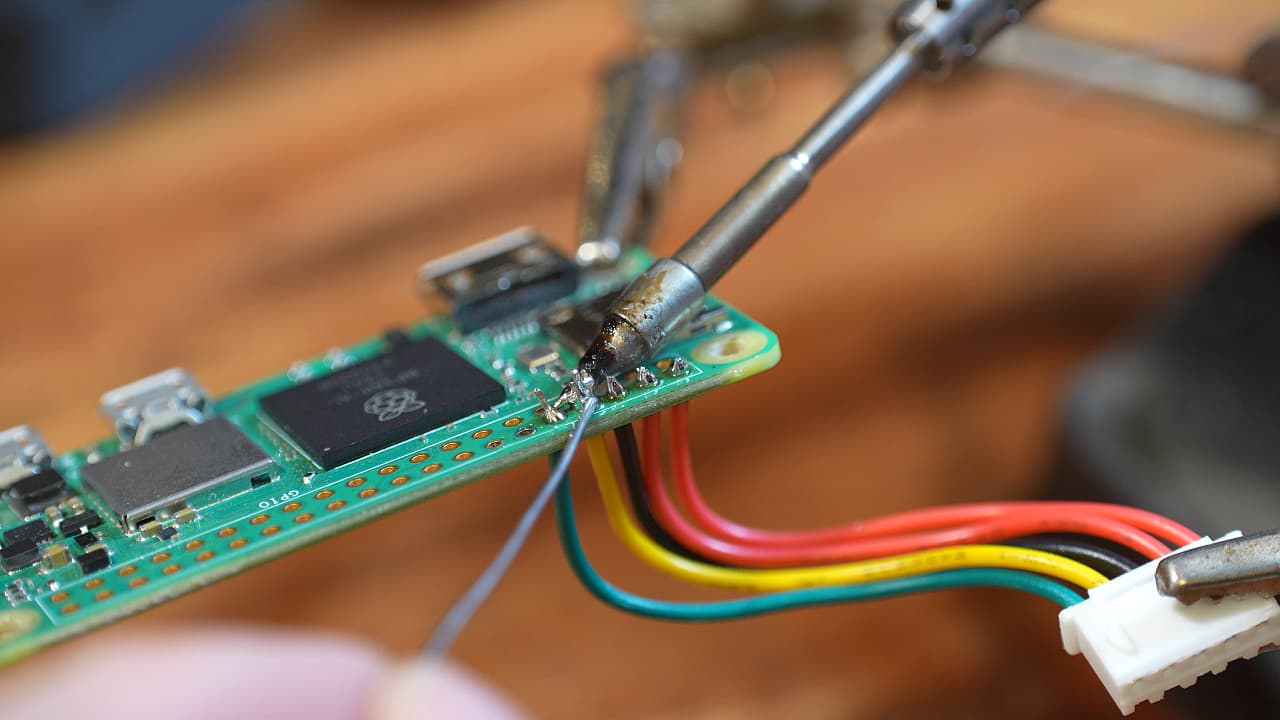

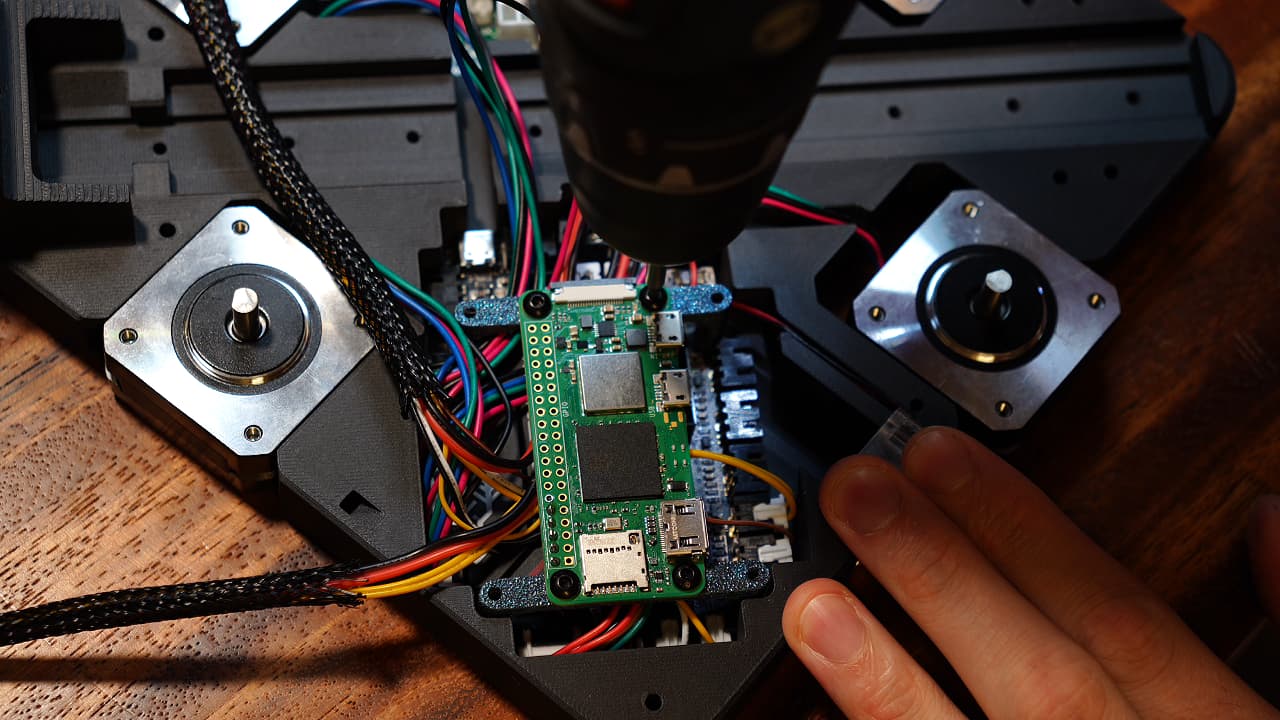

Solder the serial connector

Solder the Raspberry Pi connector as shown. You can also try using right angle pins!

Solder the Raspberry Pi connector as shown. You can also try using right angle pins! -

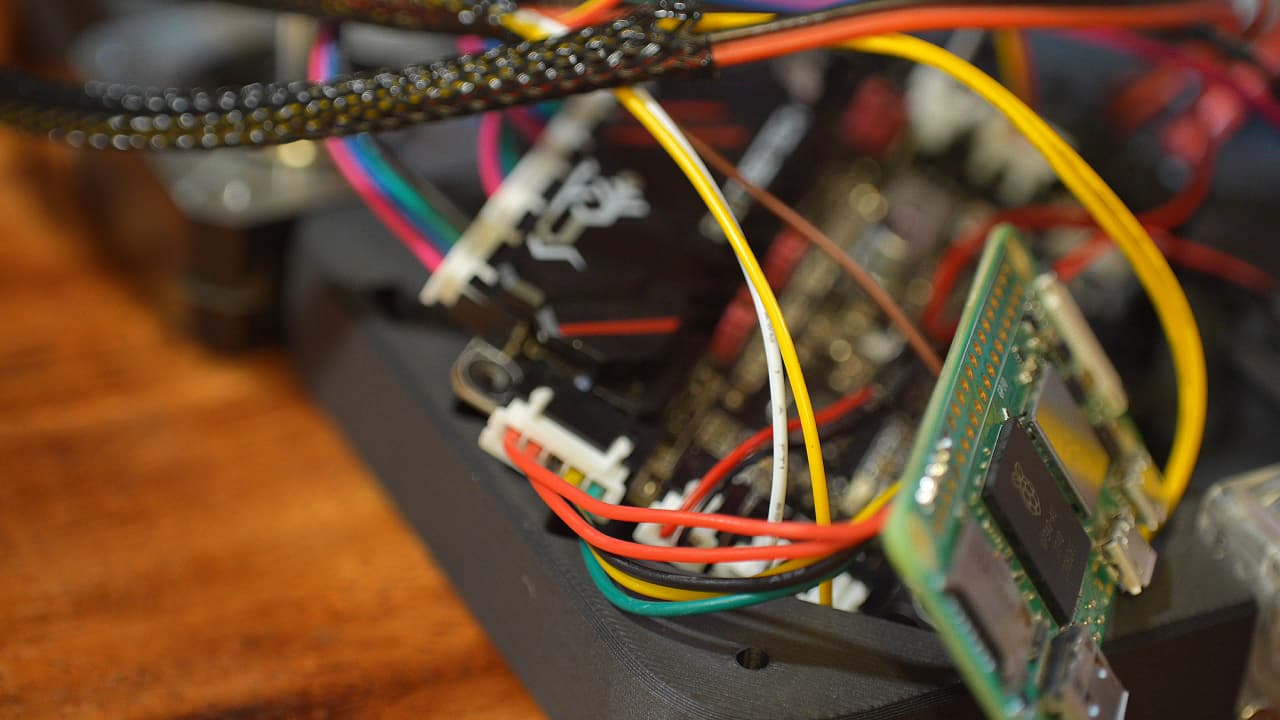

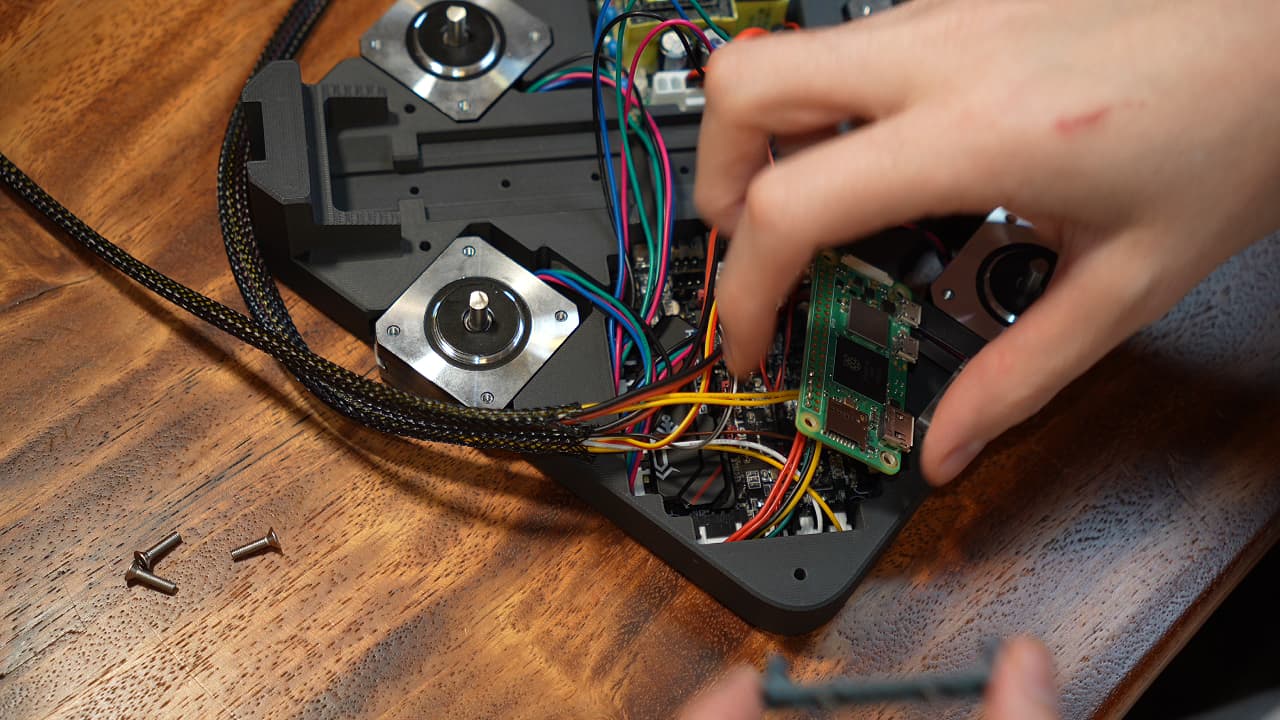

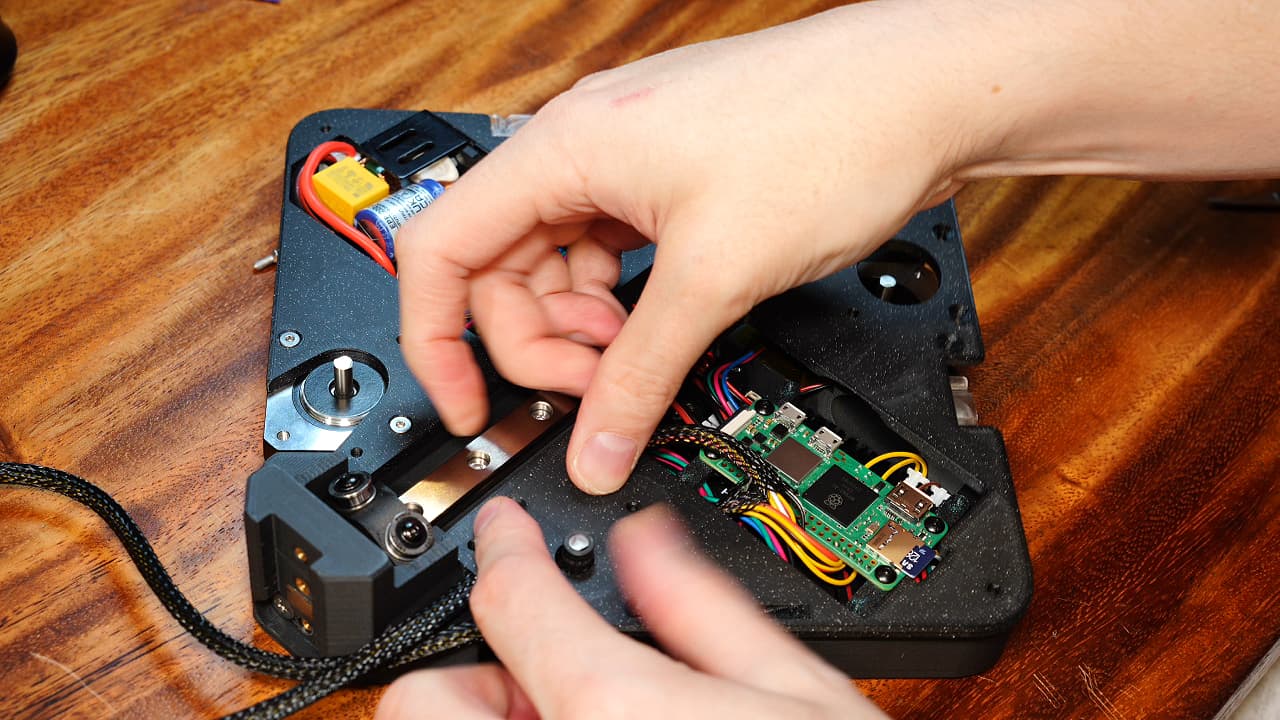

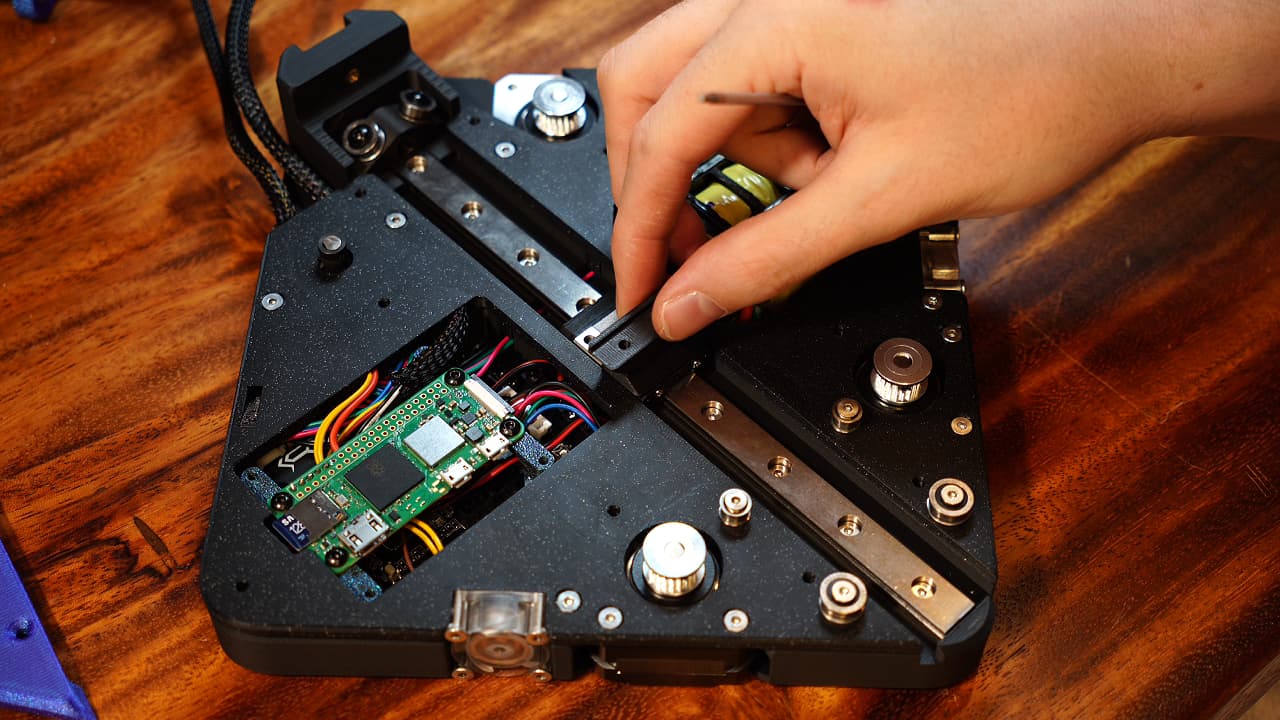

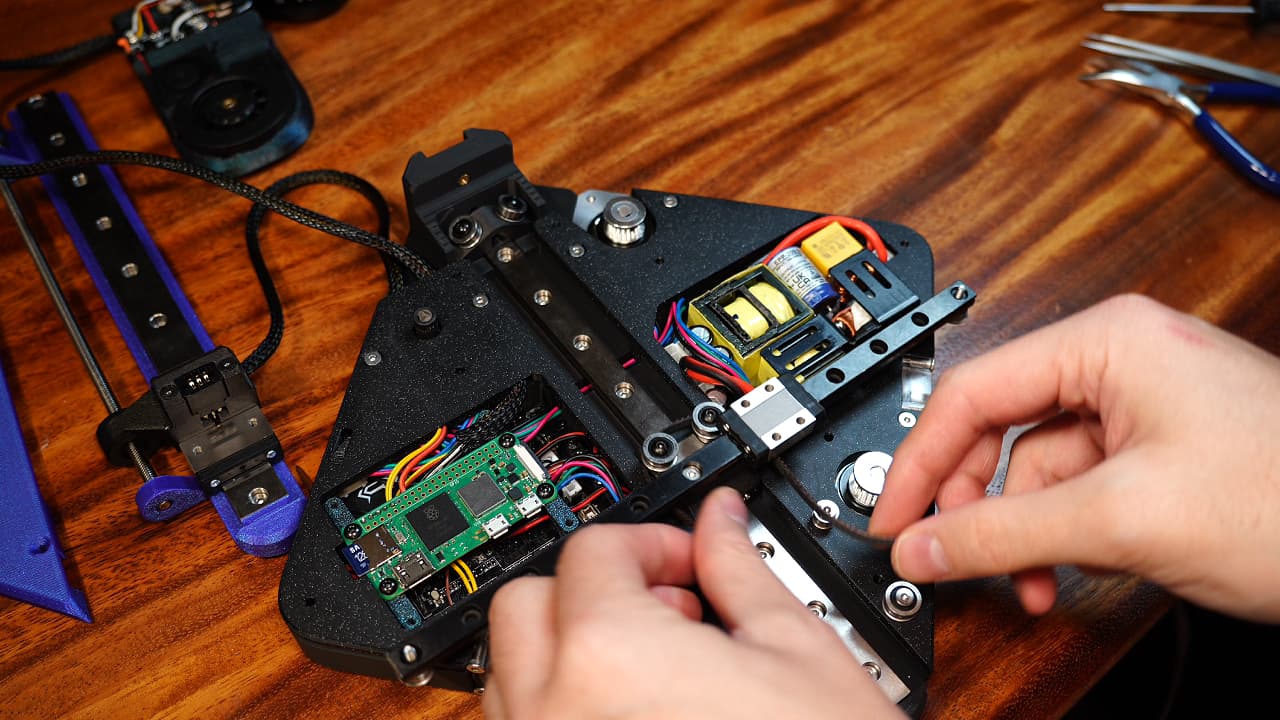

Plug in the Raspberry Pi

Connect the Raspberry Pi to the serial port.

Connect the Raspberry Pi to the serial port. -

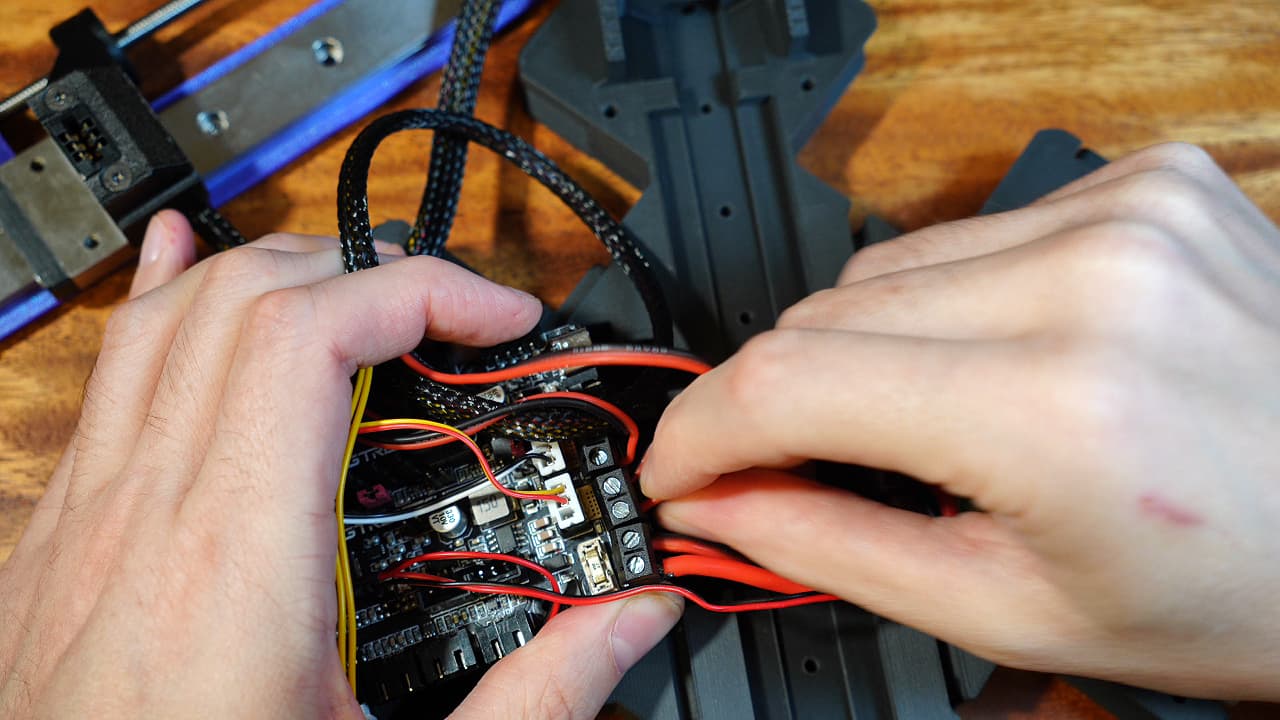

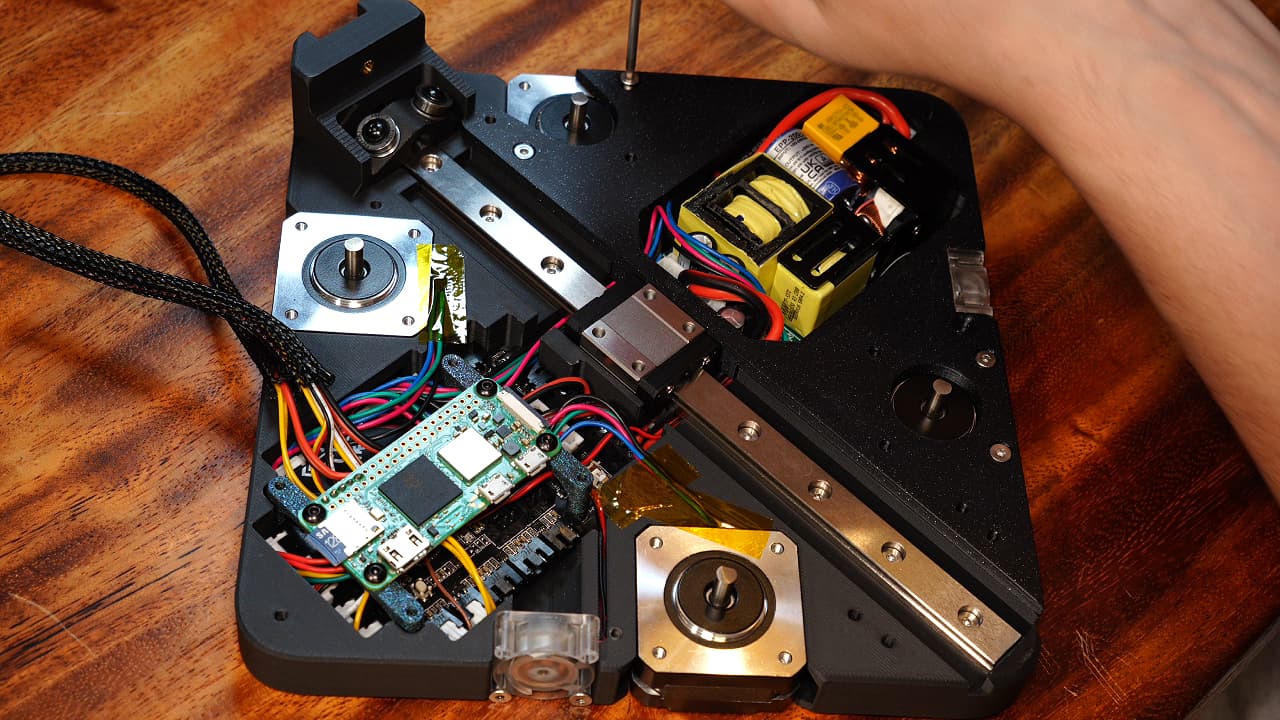

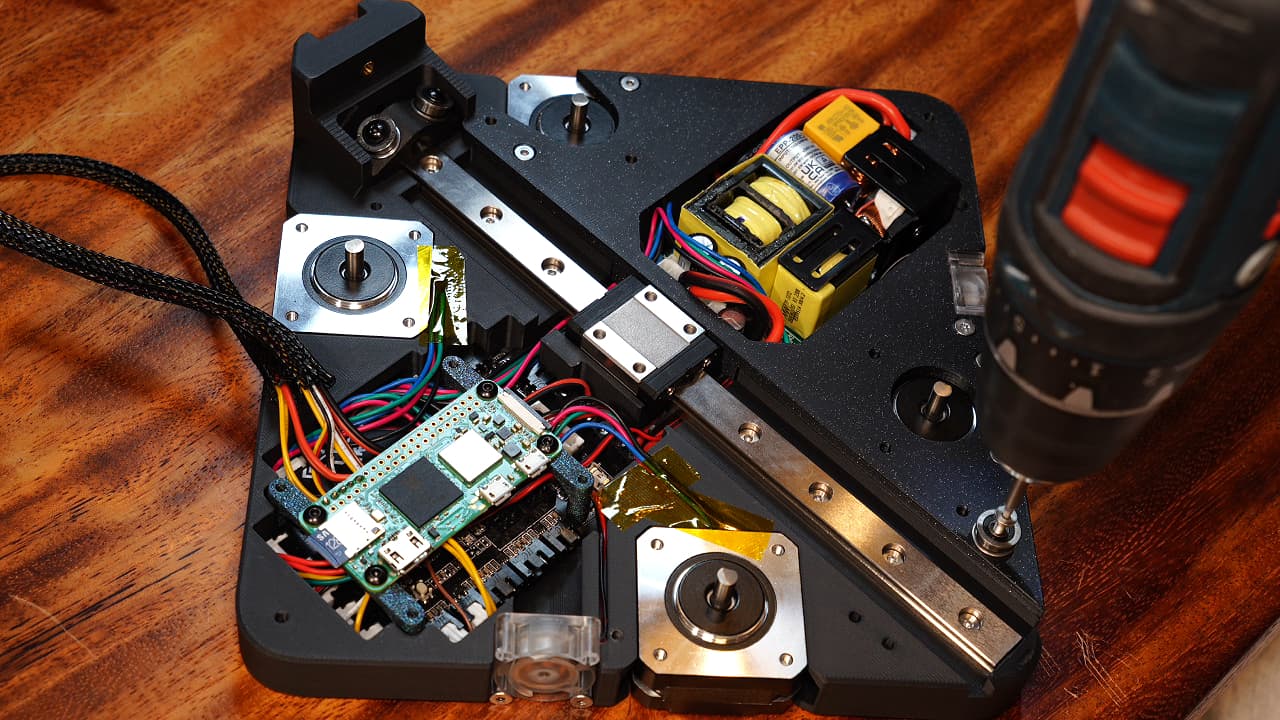

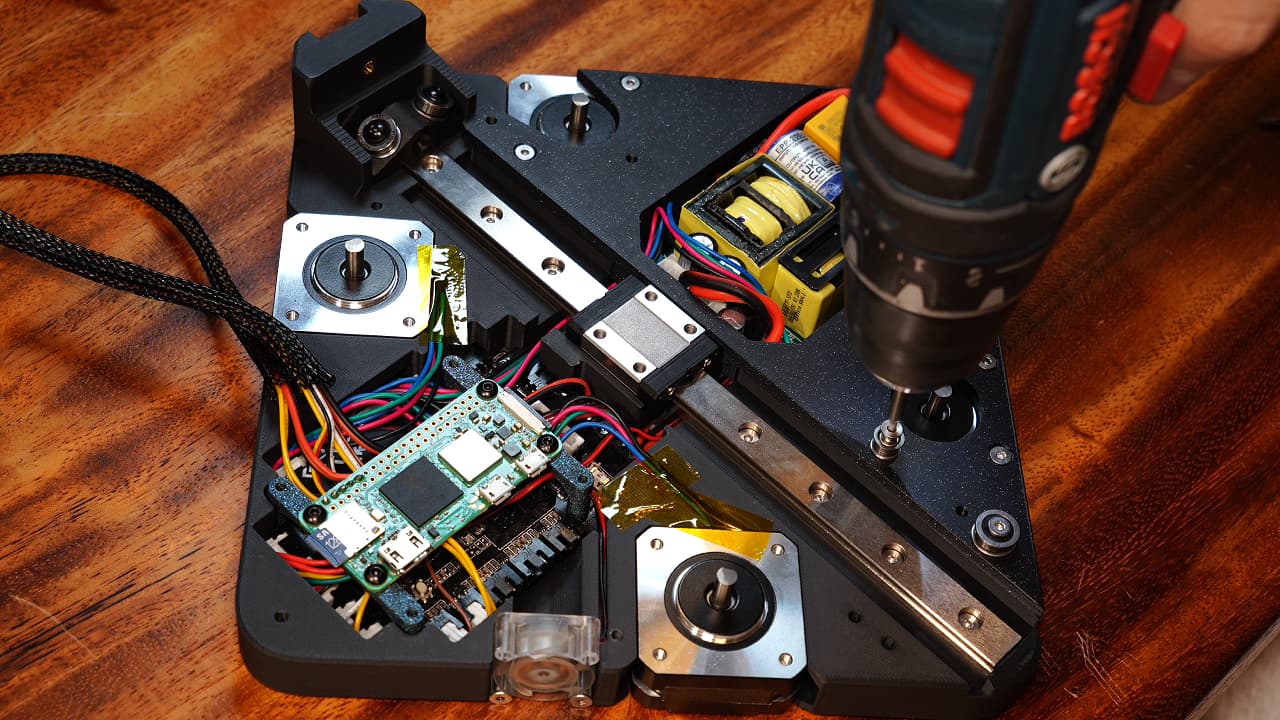

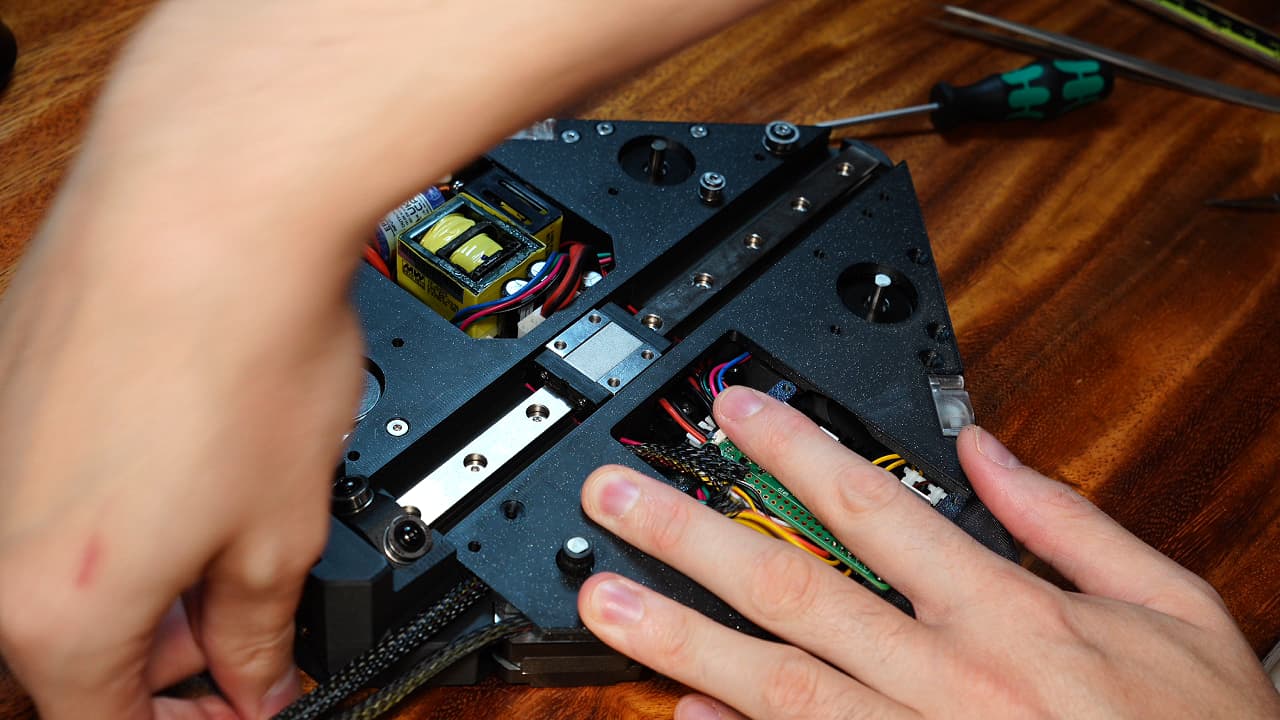

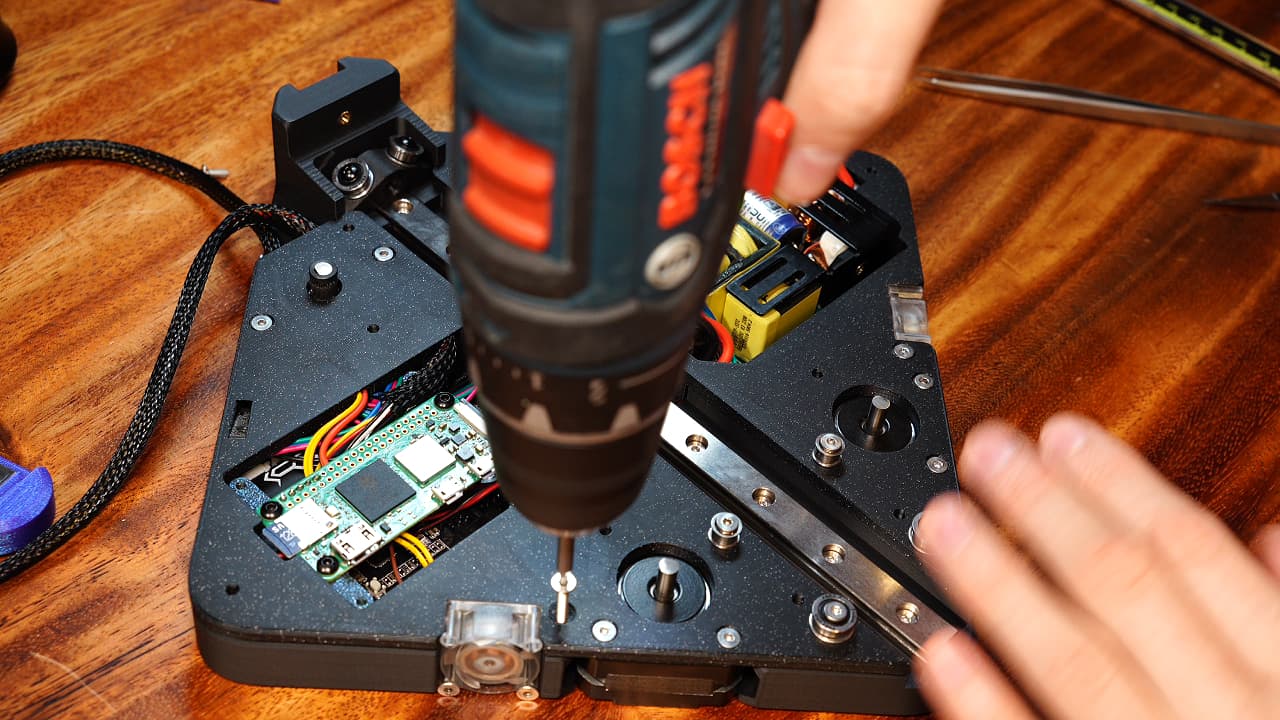

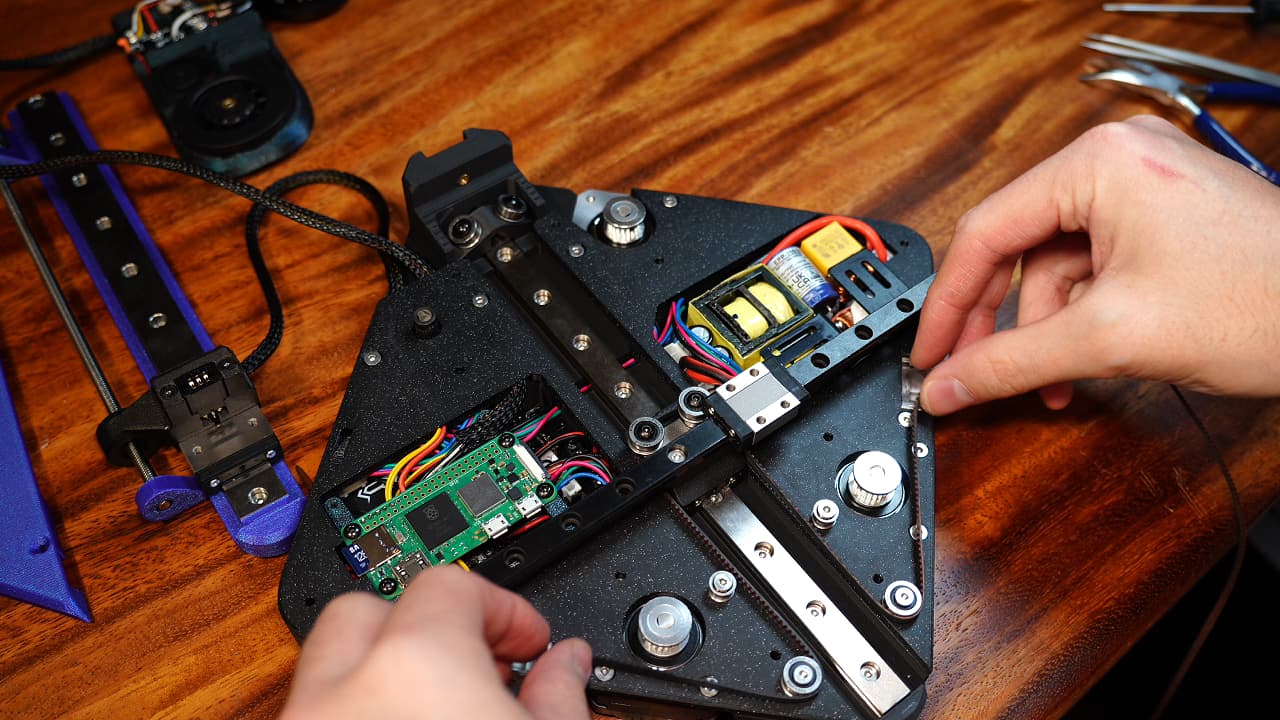

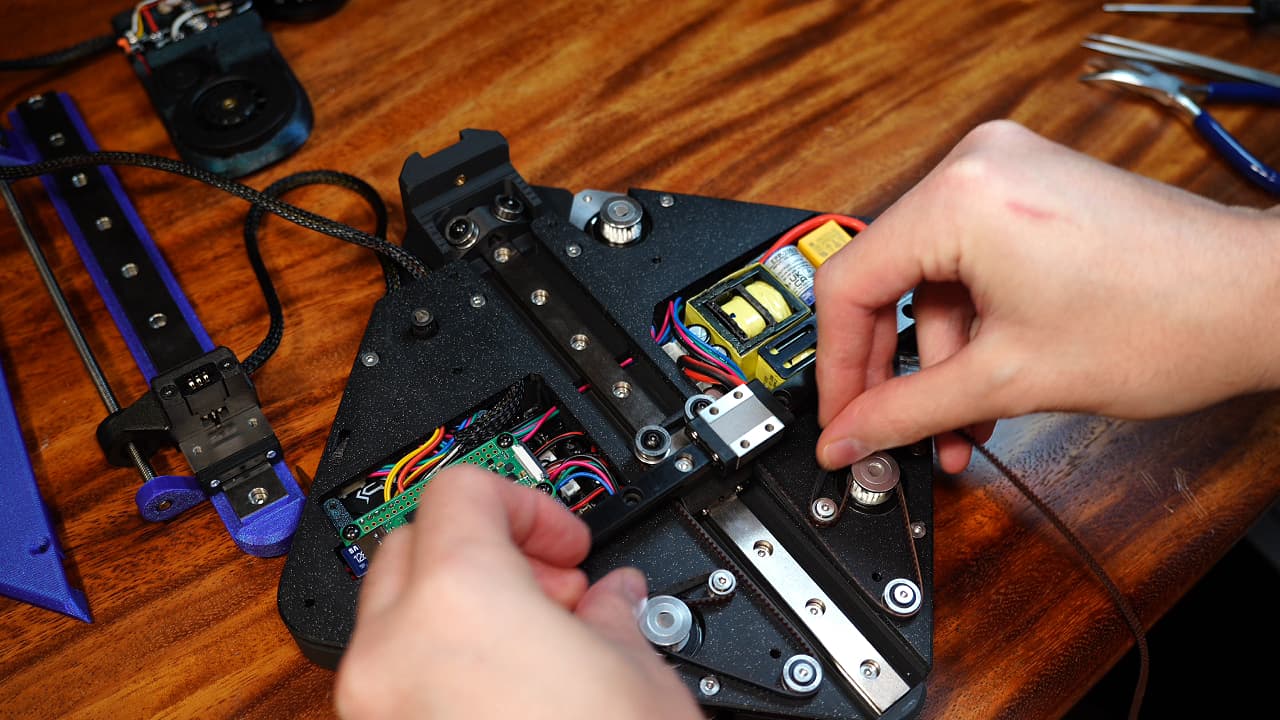

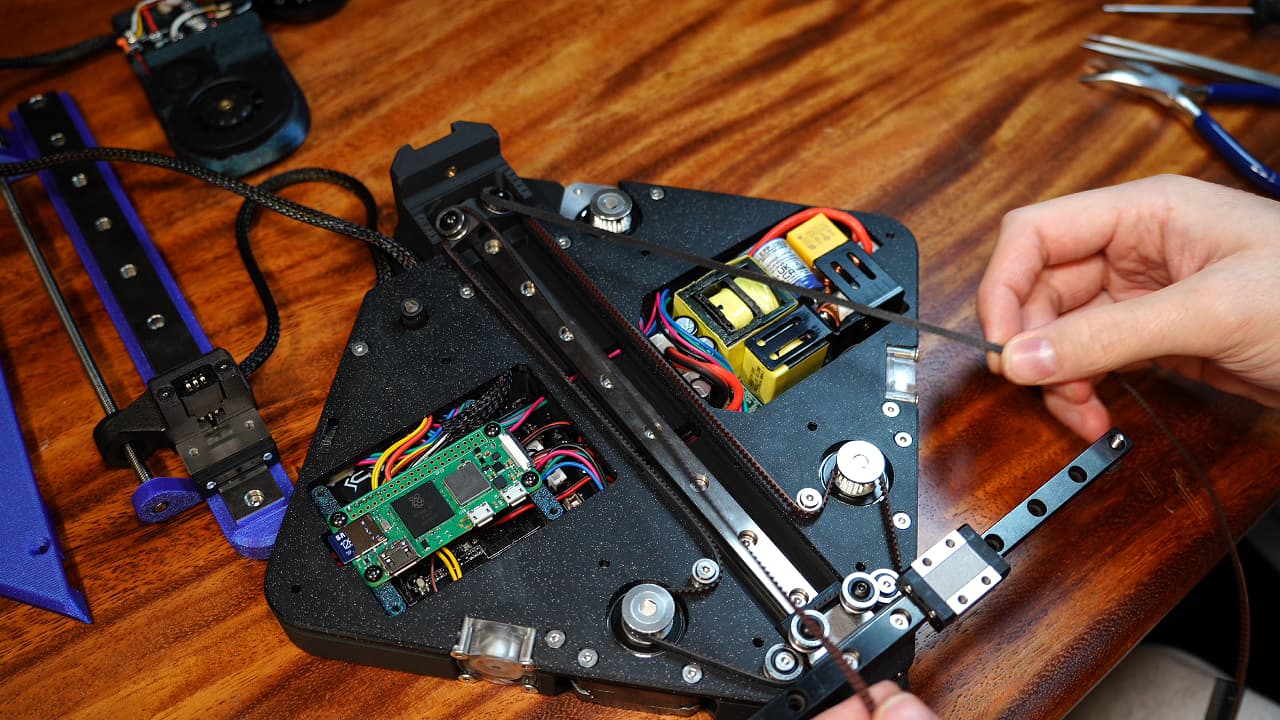

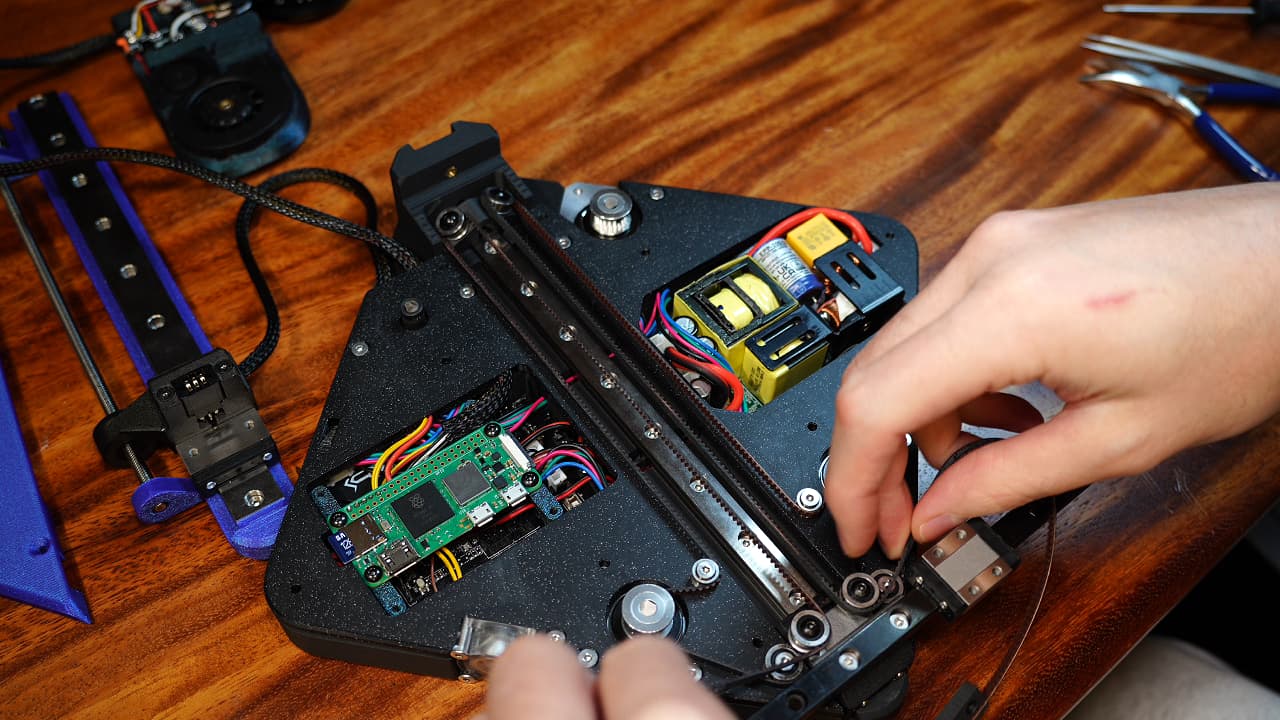

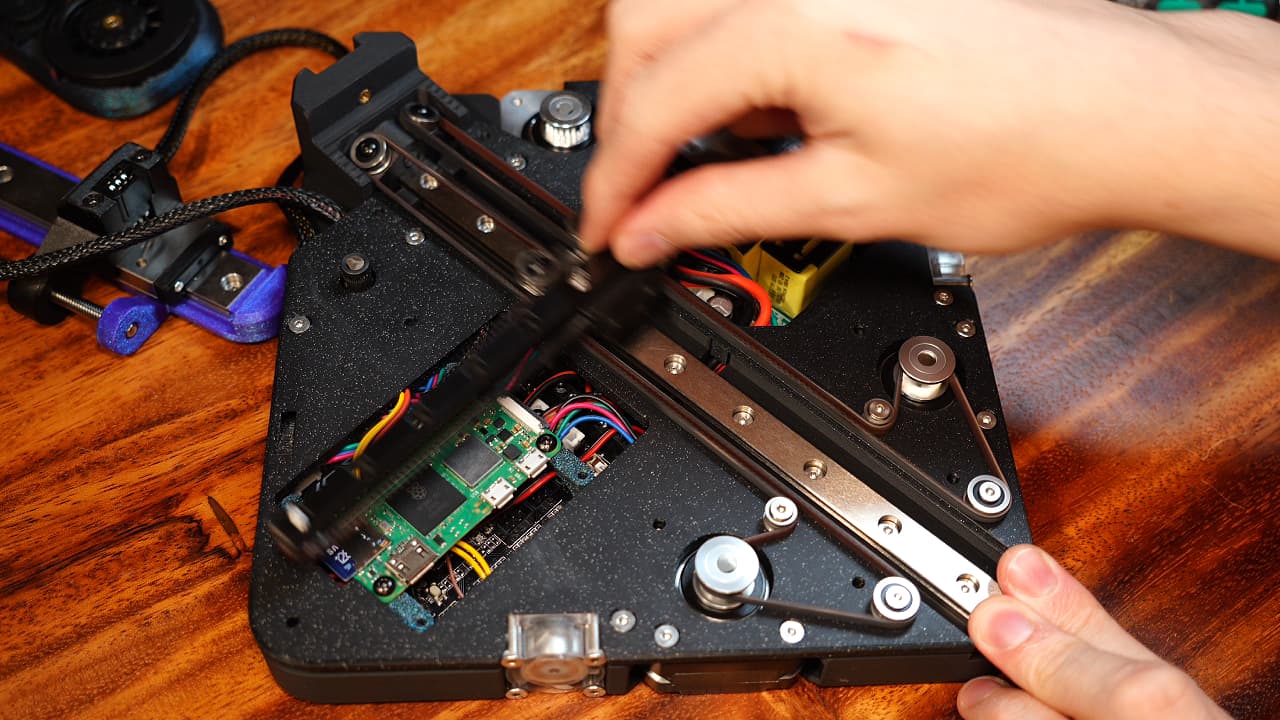

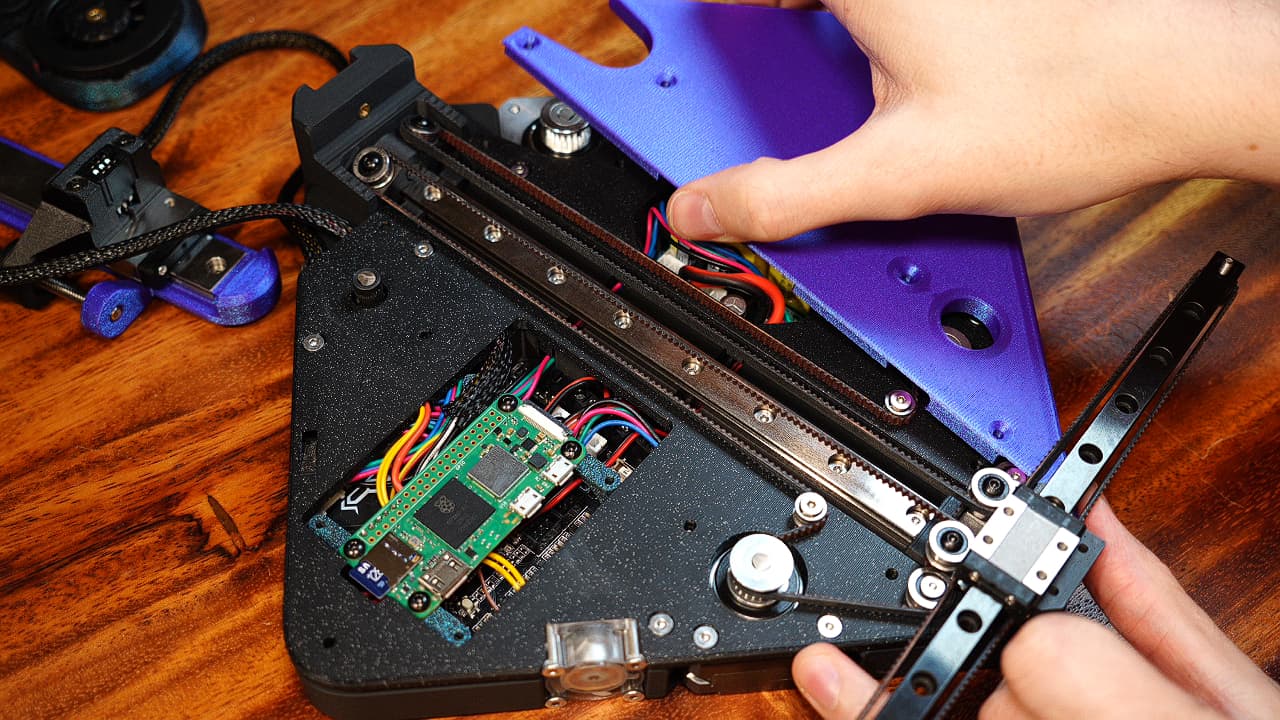

Smush the MCU

Smoosh the wires up and press the MCU into place.

Smoosh the wires up and press the MCU into place. -

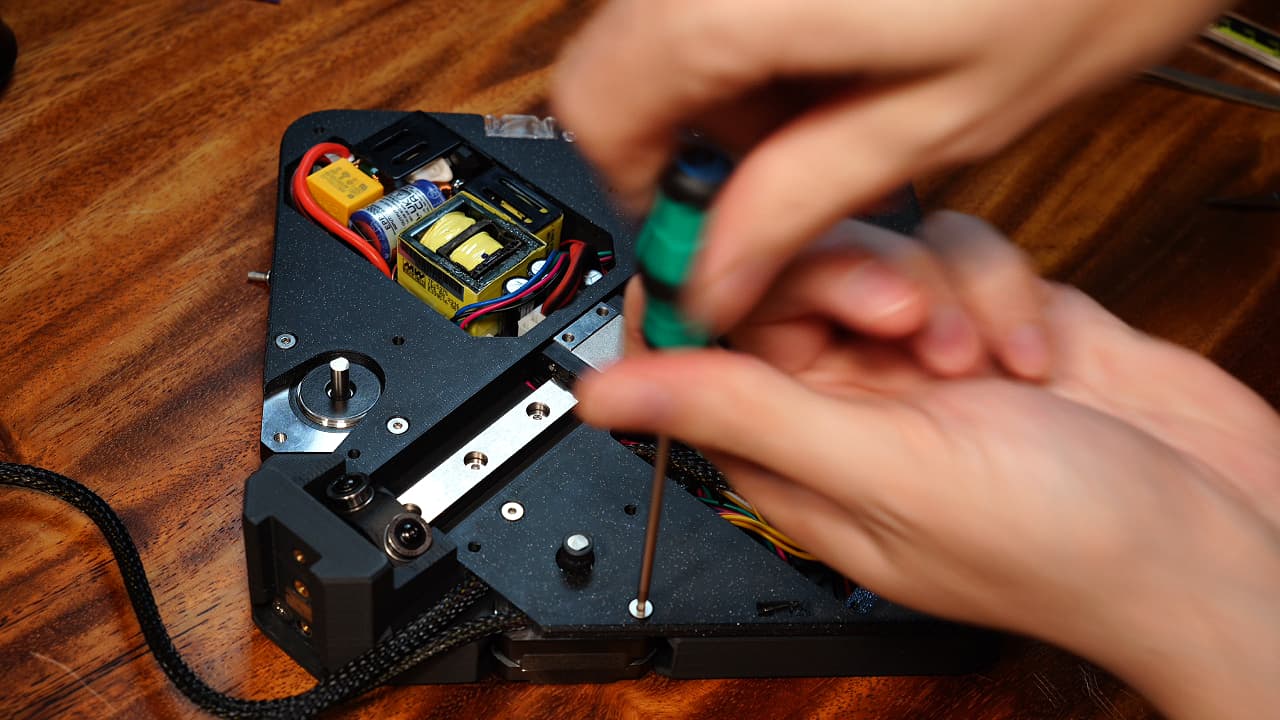

Insert the risers

Install the risers, the left one covers all the wires, and the right one covers all except the extruder motor's wires.

Install the risers, the left one covers all the wires, and the right one covers all except the extruder motor's wires. -

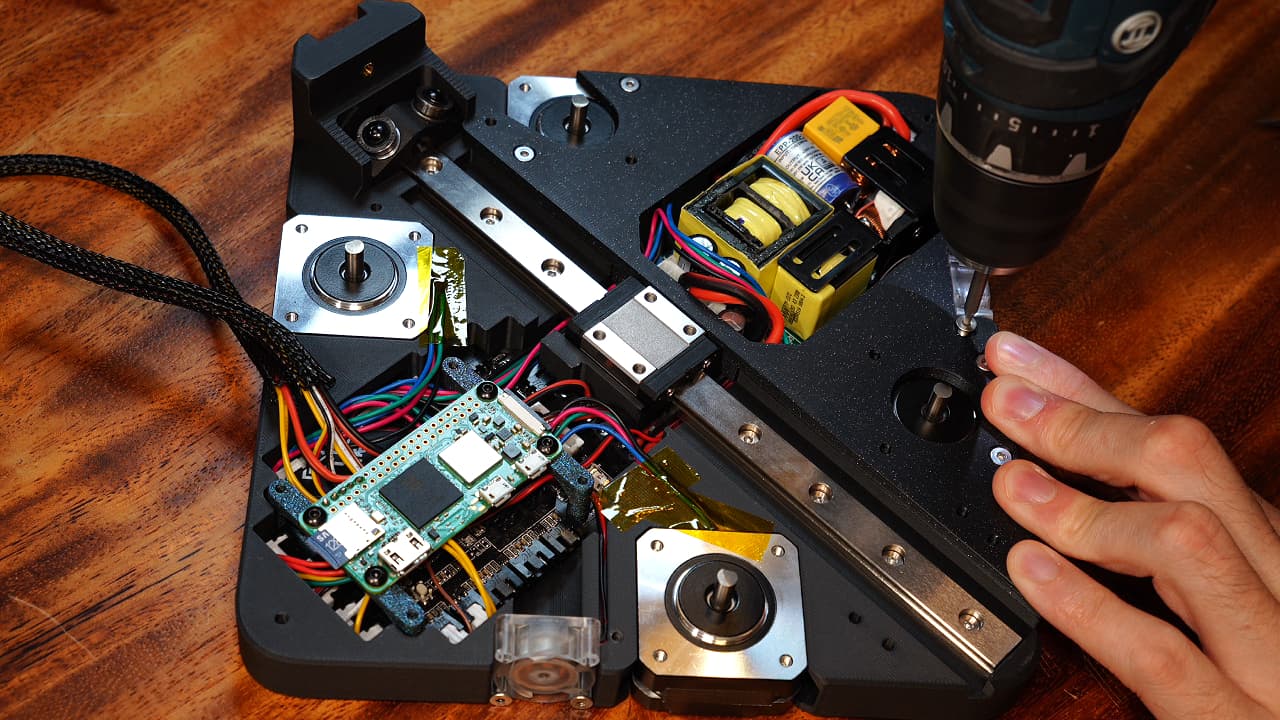

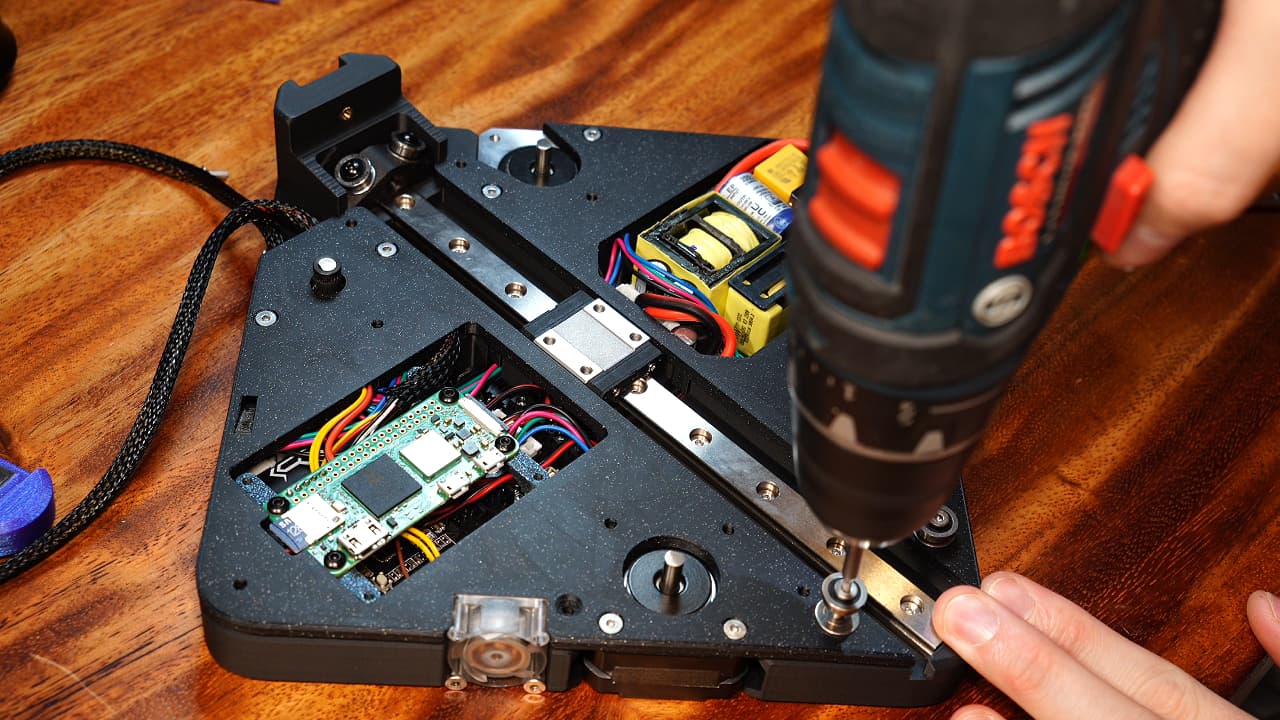

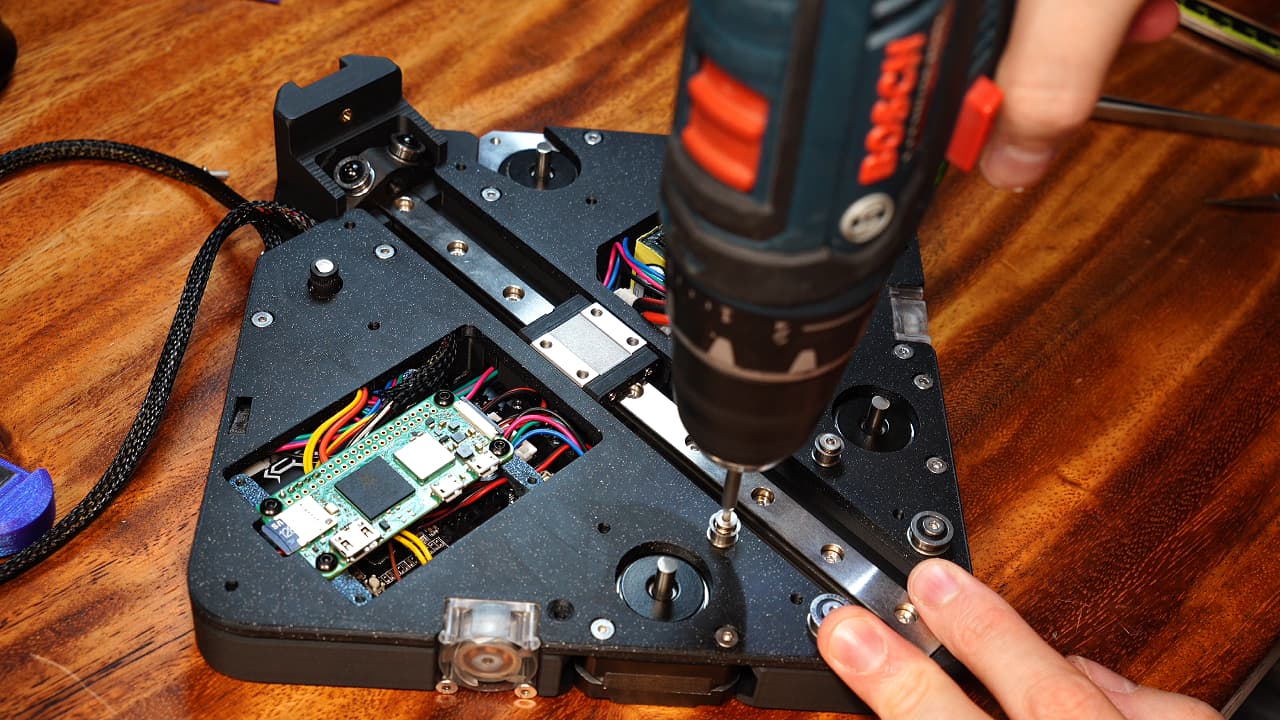

Screw in the risers

Flip it over and fix the riser in place with two 8mm countersinks.M38mm

Flip it over and fix the riser in place with two 8mm countersinks.M38mm -

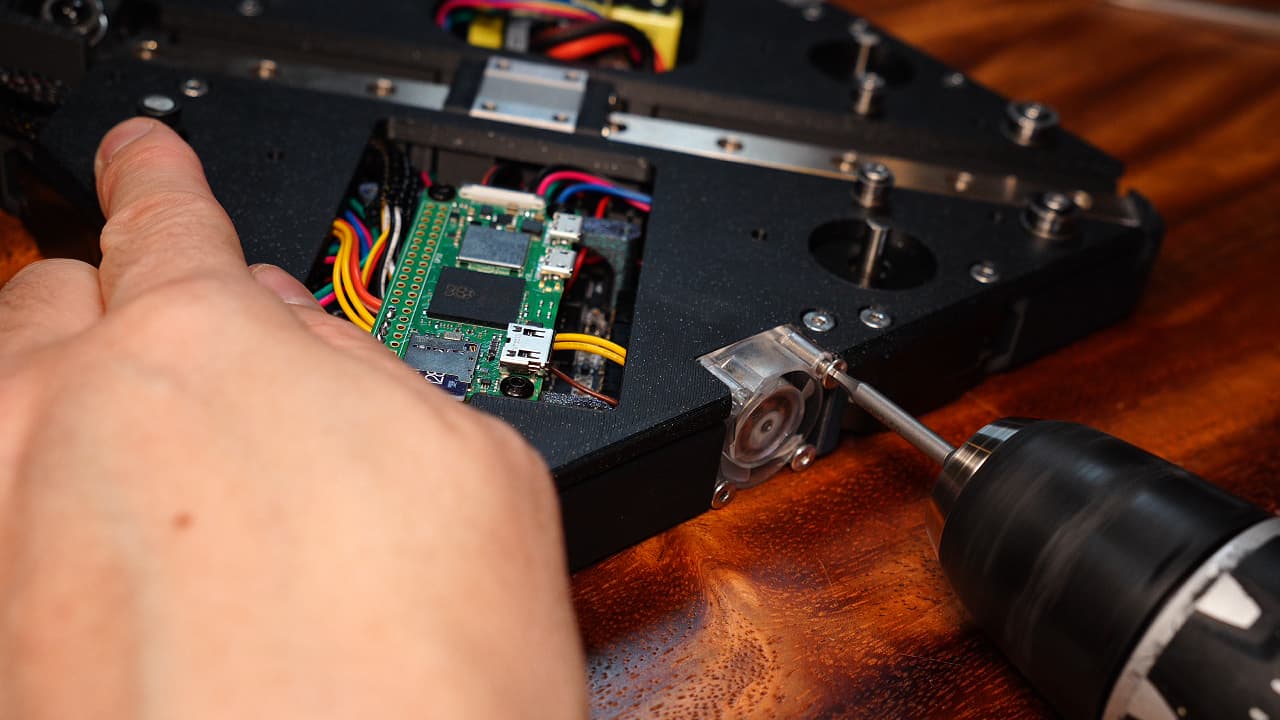

Attach Raspberry Pi

Use four screws to attach the Raspberry Pi.M2.56mm

Use four screws to attach the Raspberry Pi.M2.56mm -

Insert nut

Insert a nut onto the Y-Rail (MGN12C) by pulling it in from behind with a screw.

Insert a nut onto the Y-Rail (MGN12C) by pulling it in from behind with a screw. -

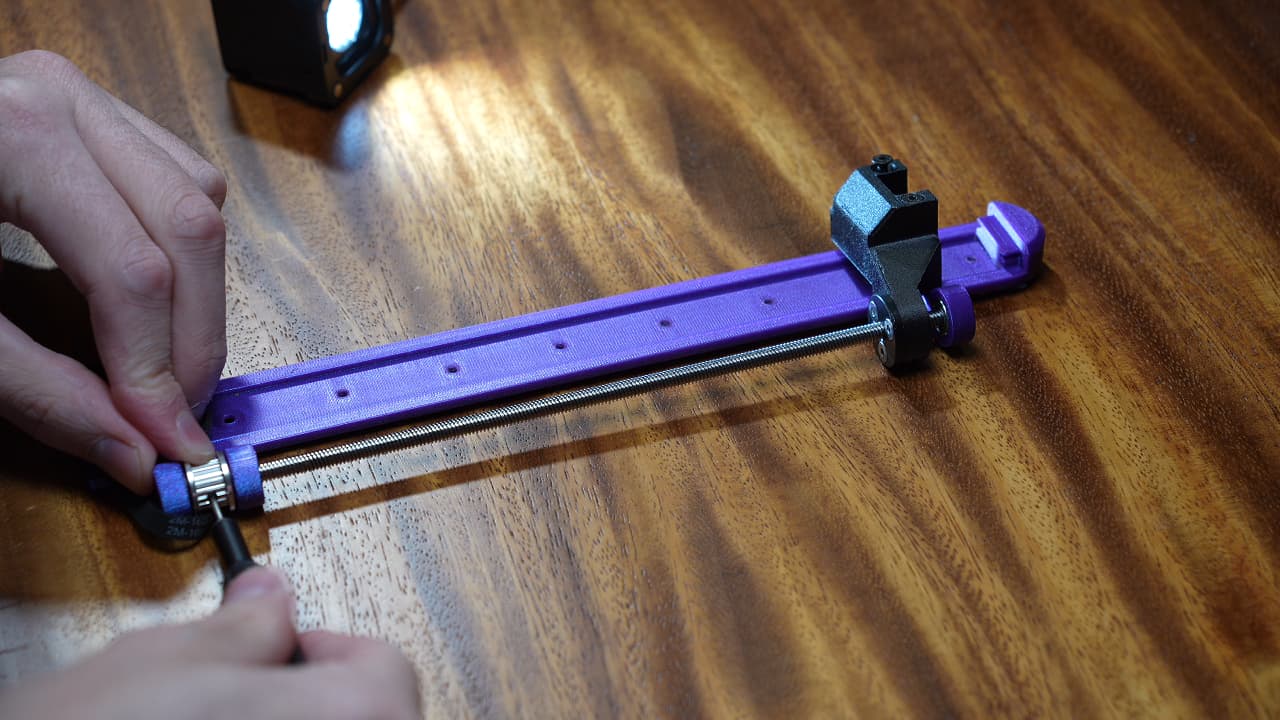

Install tensioner

On the same rail, install the tensioner over the nut.

On the same rail, install the tensioner over the nut. -

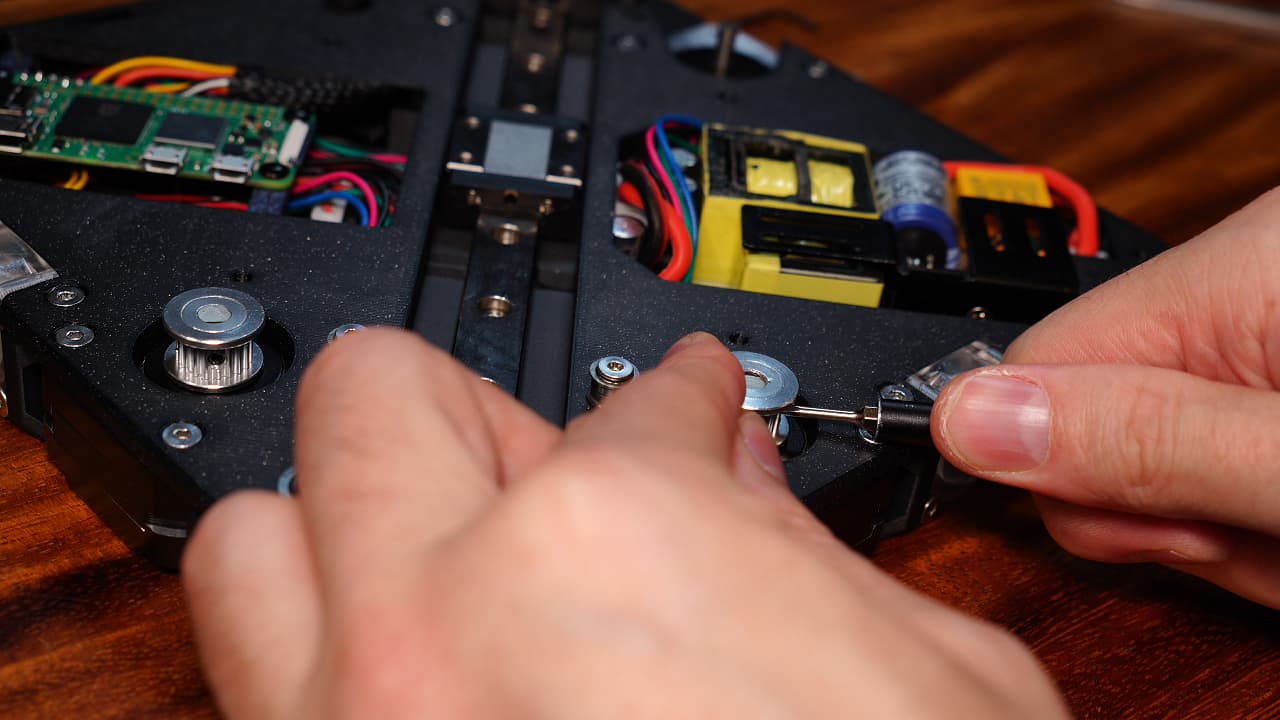

Prepare two posts

Onto the screw, drop a big bearing, a shim, and a washer.M312mm

Onto the screw, drop a big bearing, a shim, and a washer.M312mm -

Install the posts

Install the bearing posts into the tensioner.

Install the bearing posts into the tensioner. -

Install the rail

Slide in the rail. You might want to tap it down with a mallet. Verify the wires that run under the rail are tidy.

Slide in the rail. You might want to tap it down with a mallet. Verify the wires that run under the rail are tidy. -

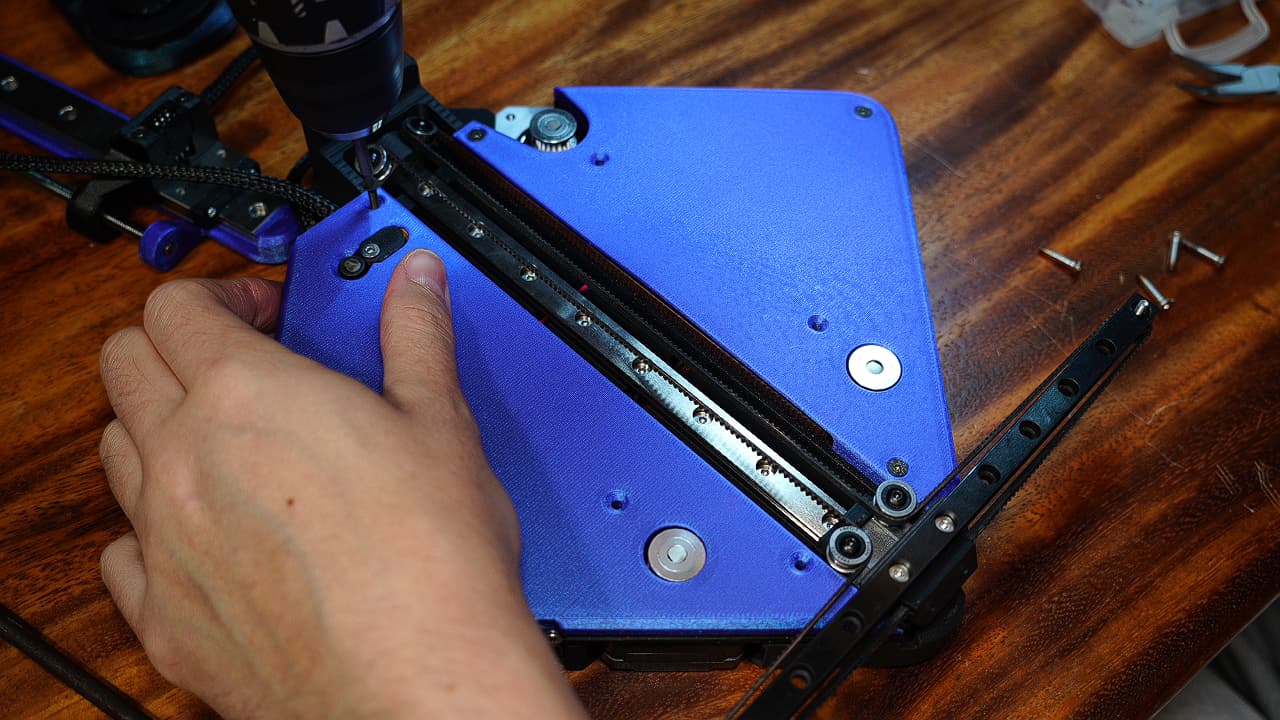

Fasten the rail

Screw the rail to the chassis. You must go slow, alternate short rotations and don't overheat the plastic.M314mm

Screw the rail to the chassis. You must go slow, alternate short rotations and don't overheat the plastic.M314mm -

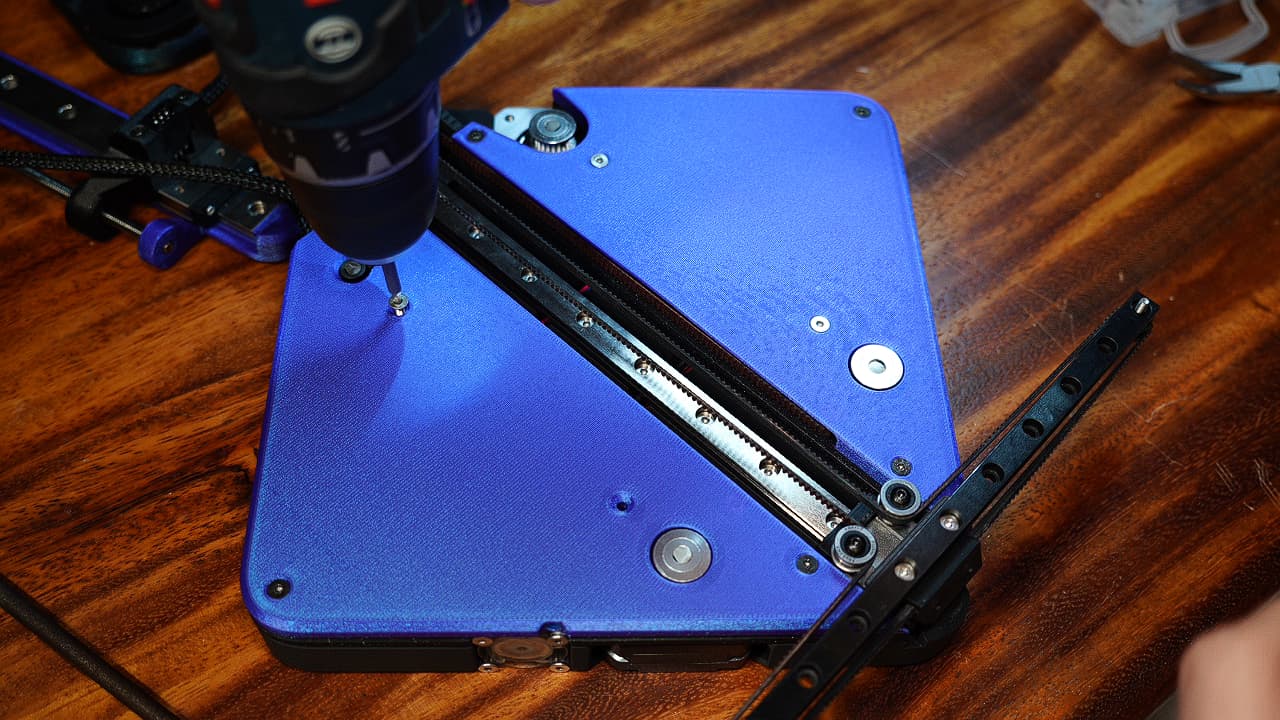

Insert the bonus screw

From the bottom, fasten the rail tightly to the chassis.M320mm

From the bottom, fasten the rail tightly to the chassis.M320mm -

Tape the motors

Tape the motors. Without tape, the wires will fly away. You need to tape it before installing the mid plates.

Tape the motors. Without tape, the wires will fly away. You need to tape it before installing the mid plates. -

Install the right midplate

Drop the right midplate on top of the motors, making sure you can press it flat. Verify from every angle that there is no gap.

Drop the right midplate on top of the motors, making sure you can press it flat. Verify from every angle that there is no gap. -

Secure the right motors

Secure the motors to the right midplate, filling the four countersunk motor mount holes.M38mm

Secure the motors to the right midplate, filling the four countersunk motor mount holes.M38mm -

Install the extra screw

Add another screw to further secure the midplate to the chassis.M320mm

Add another screw to further secure the midplate to the chassis.M320mm -

Install the lower pulley

Onto the screws, drop a big bearing, a medium shim, and a big washer. Screw it all the way through the chassis.M325mm

Onto the screws, drop a big bearing, a medium shim, and a big washer. Screw it all the way through the chassis.M325mm -

Install the upper pulley

Onto the screws, drop a small flanged bearing, a small shim, another small flanged bearing, and another small shim. This post threads into the motor. The flanges serve as guides for the belt.M314mm

Onto the screws, drop a small flanged bearing, a small shim, another small flanged bearing, and another small shim. This post threads into the motor. The flanges serve as guides for the belt.M314mm -

Install extruder gear

On the top left motor, and using several fingers, line up the top of the extruder gear with a pulley and fasten the grub screw to the flat side of the shaft.

On the top left motor, and using several fingers, line up the top of the extruder gear with a pulley and fasten the grub screw to the flat side of the shaft. -

Install left midplate

Insert the wire harnesses into the slots in the midplate and lay the midplate into position. Verify there is no gap.

Insert the wire harnesses into the slots in the midplate and lay the midplate into position. Verify there is no gap. -

Tug the cables

Remove the slack in the cables.

Remove the slack in the cables. -

Insert the motor mount screws

Secure the motors to the left midplate, filling the four countersunk motor mount holes with 8mm countersinks.M38mm

Secure the motors to the left midplate, filling the four countersunk motor mount holes with 8mm countersinks.M38mm -

Insert the lower pulley

Same as the right one.

Same as the right one. -

Insert the upper pulley

Same as the right one.

Same as the right one. -

Install the extra screw

Add another screw to further secure the midplate to the chassis.M320mm

Add another screw to further secure the midplate to the chassis.M320mm -

Finish right fan

Secure the right fan's top two screw holes.M314mm

Secure the right fan's top two screw holes.M314mm -

Finish left fan

Secure the left fan's top two screw holes.M314mm

Secure the left fan's top two screw holes.M314mm -

Install left drive pulley

Temporarily put two sheets of paper under the pulley before tightening the grub screw to the flat side of the shaft. If there are two grub screws, tighten them both but one should be on the flat side of the shaft.

Temporarily put two sheets of paper under the pulley before tightening the grub screw to the flat side of the shaft. If there are two grub screws, tighten them both but one should be on the flat side of the shaft. -

Install right drive pulley

Repeat on the right. Verify the pulleys are friction-free by grabbing the pulley forcefully and rotating it a full circle. If it catches on something, it's going to show up in your prints.

Repeat on the right. Verify the pulleys are friction-free by grabbing the pulley forcefully and rotating it a full circle. If it catches on something, it's going to show up in your prints. -

Modify X rail

Cut one hole off the X rail (MGN9C).

Cut one hole off the X rail (MGN9C). -

Install right drive pulley

Add a nut to both sides of the rail.

Add a nut to both sides of the rail. -

Create bearing posts

On the screws, drop a big bearing and a medium shim.M314mm

On the screws, drop a big bearing and a medium shim.M314mm -

Install bearing posts

On both sides of the rail tighten down both bearing posts.

On both sides of the rail tighten down both bearing posts. -

Drop on the spacer

Drop the spacer (printed) onto the Y axis carriage.

Drop the spacer (printed) onto the Y axis carriage. -

Attach the X rail

Drop the X rail on top of the spacer and screw it in with two screws.M320mm

Drop the X rail on top of the spacer and screw it in with two screws.M320mm -

Create bearing towers

On the screws, drop a big bearing, a medium shim, a large washer, a small shim, a small flanged bearing, small shim, small normal bearing, and small shim.M316mmThe belt rides on the normal bearing and the flanged bearing prevents it from riding up.

On the screws, drop a big bearing, a medium shim, a large washer, a small shim, a small flanged bearing, small shim, small normal bearing, and small shim.M316mmThe belt rides on the normal bearing and the flanged bearing prevents it from riding up. -

Install bearing towers

Screw the two bearing towers into the top positions in the Y carriage.

Screw the two bearing towers into the top positions in the Y carriage. -

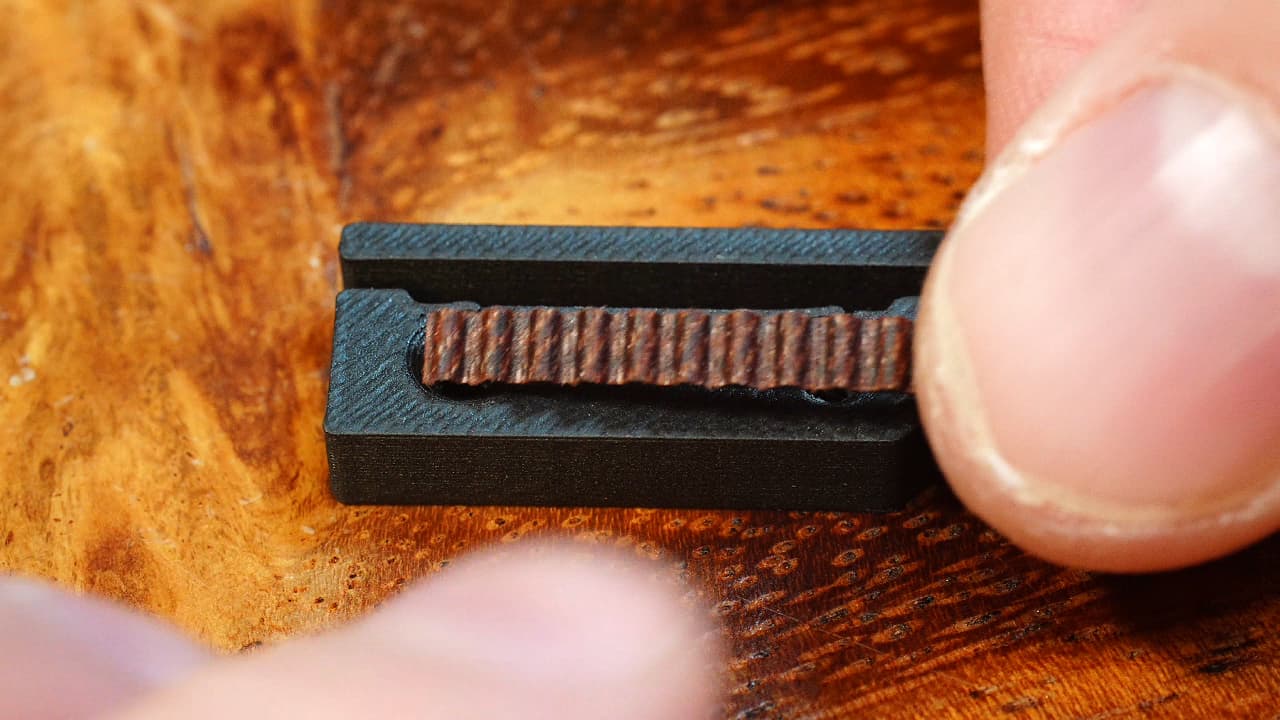

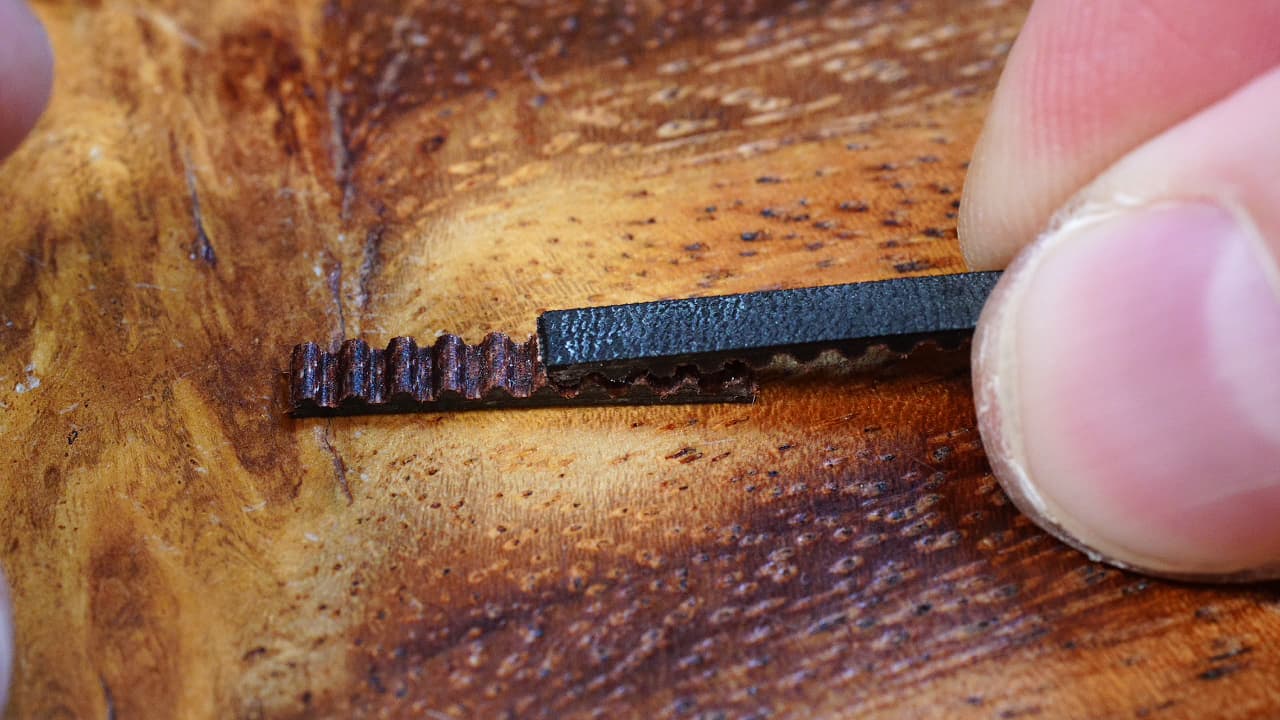

Cut a piece of belt

Cut a piece of belt that precisely fits into the recess in the belt clip.

Cut a piece of belt that precisely fits into the recess in the belt clip. -

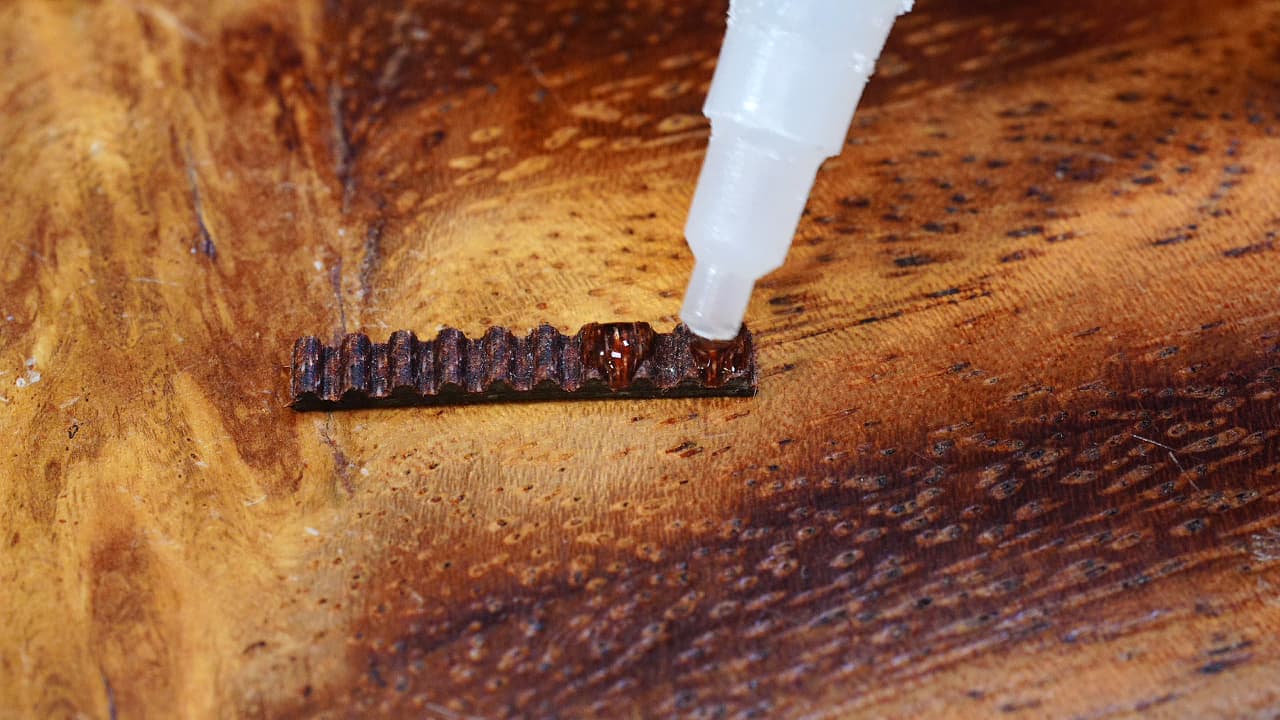

Dap some super glue

O P T I O N A L Dap some super glue on the belt. The glue is not required, but it really makes it easier to put the belt into the clip.

Dap some super glue on the belt. The glue is not required, but it really makes it easier to put the belt into the clip. -

Link the belts

Hold the long piece of belt to the short one, overlapping half of it as shown.

Hold the long piece of belt to the short one, overlapping half of it as shown. -

Insert one side

Insert the belt into the clip and verify that the short belt is seated properly.

Insert the belt into the clip and verify that the short belt is seated properly. -

Insert the other side

Insert the other side of the belt temporarily. You can trim it later.

Insert the other side of the belt temporarily. You can trim it later. -

Lubricate belts

Lubricate the sides of the belt (not the teeth) with silicone based lube. Don't AT me for using sex lube, it's a joke.

Lubricate the sides of the belt (not the teeth) with silicone based lube. Don't AT me for using sex lube, it's a joke. -

Route the belts

Hook the belt over the towers, placing it on the lowest bearing.

Hook the belt over the towers, placing it on the lowest bearing. -

Around the lower bearings

Hook the lower bearings.

Hook the lower bearings. -

Around the upper bearings

Wrapping around the drive pulleys, hook the upper bearings.

Wrapping around the drive pulleys, hook the upper bearings. -

Around the tensioner

Wrap the belts around the tensioner bearings, the two strands coming down the middle.

Wrap the belts around the tensioner bearings, the two strands coming down the middle. -

Around the tower again

Hook the tower bearings, this time the upper ones, heading out to the X rail bearings.

Hook the tower bearings, this time the upper ones, heading out to the X rail bearings. -

Around the X rail

Route the belt around the X rail. Trim the excess and reattach the belt to the clip.

Route the belt around the X rail. Trim the excess and reattach the belt to the clip. -

Screw in the tensioner

Push the tensioner towards the Z block, then fix the tensioner in place with a screw. This should be loose.M325mm

Push the tensioner towards the Z block, then fix the tensioner in place with a screw. This should be loose.M325mm -

Thoroughly test

Thoroughly test and tune the belt tension. When you feel that the friction is negligible, it's ready.

Thoroughly test and tune the belt tension. When you feel that the friction is negligible, it's ready. -

Install top plates

Drop in the two top plates.

Drop in the two top plates. -

Fasten the outer screws

Fasten the top plates to the chassis on the 6 outer holes along the edges.M320mm

Fasten the top plates to the chassis on the 6 outer holes along the edges.M320mm -

Fasten the inner screws

Fasten the top plates to the motors on the 4 inner holes. Bonus points if you fabricate 15mm countersinks for a better fit.M314mm

Fasten the top plates to the motors on the 4 inner holes. Bonus points if you fabricate 15mm countersinks for a better fit.M314mm -

Attach the tool head

Drop on the tool head.

Drop on the tool head. -

Screw on the tool head

Screw on the tool head.M314mm

Screw on the tool head.M314mm -

Attach the belt clip

Flip over the printer and attach the clip with two screws.M38mm

Flip over the printer and attach the clip with two screws.M38mm -

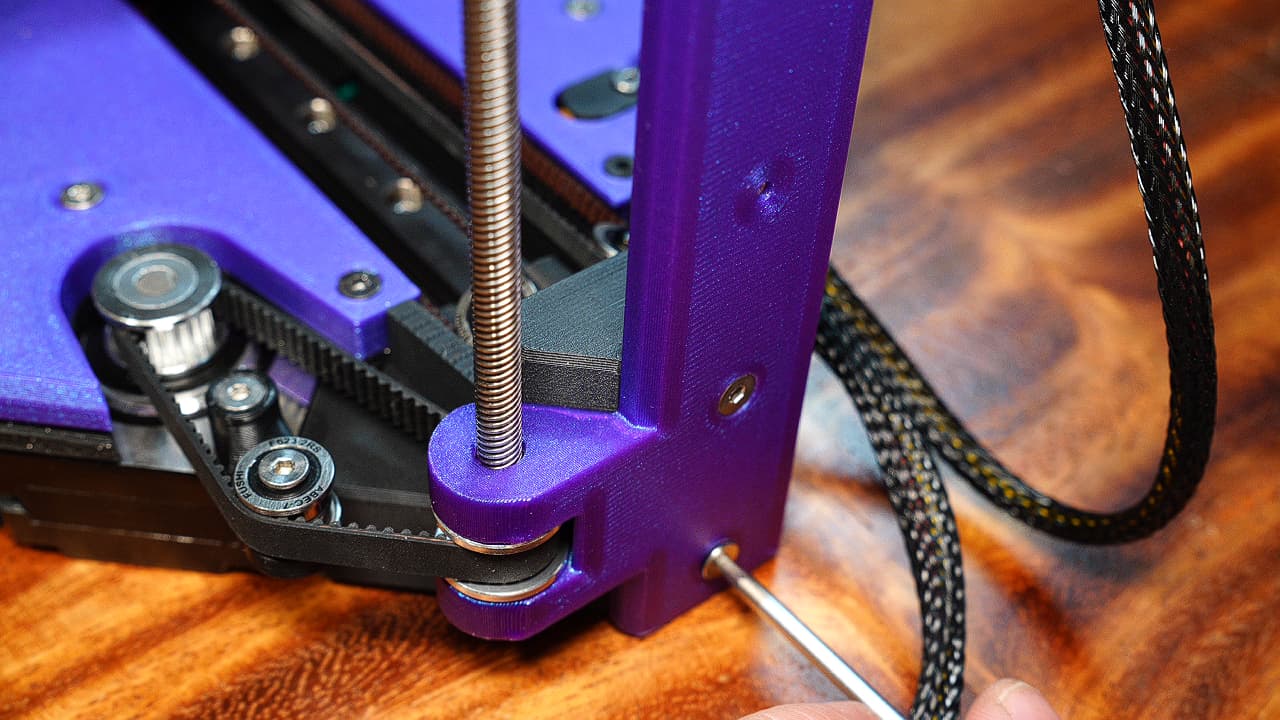

Attach the Z idler arm

Attach the z idler arm. To make the bearing stack, on a 14mm wafer head, drop a big bearing, medium shim, big bearing, and medium shim.M314mm

Attach the z idler arm. To make the bearing stack, on a 14mm wafer head, drop a big bearing, medium shim, big bearing, and medium shim.M314mm -

Attach the Z axis

Hook the Z axis drive belt on the pulley. Drop the Z axis into place. Tighten the idler arm.

Hook the Z axis drive belt on the pulley. Drop the Z axis into place. Tighten the idler arm. -

Screw in Z axis

Screw in the Z axis. Rev B uses two button heads instead of the countersinks shown in the picture.M316mm

Screw in the Z axis. Rev B uses two button heads instead of the countersinks shown in the picture.M316mm -

Rough up bowden tube

Rough up at least 1cm of the bowden tube.

Rough up at least 1cm of the bowden tube. -

Pour glue on bowden tube

Pour a generous amount of glue on the end of the bowden tube.

Pour a generous amount of glue on the end of the bowden tube. -

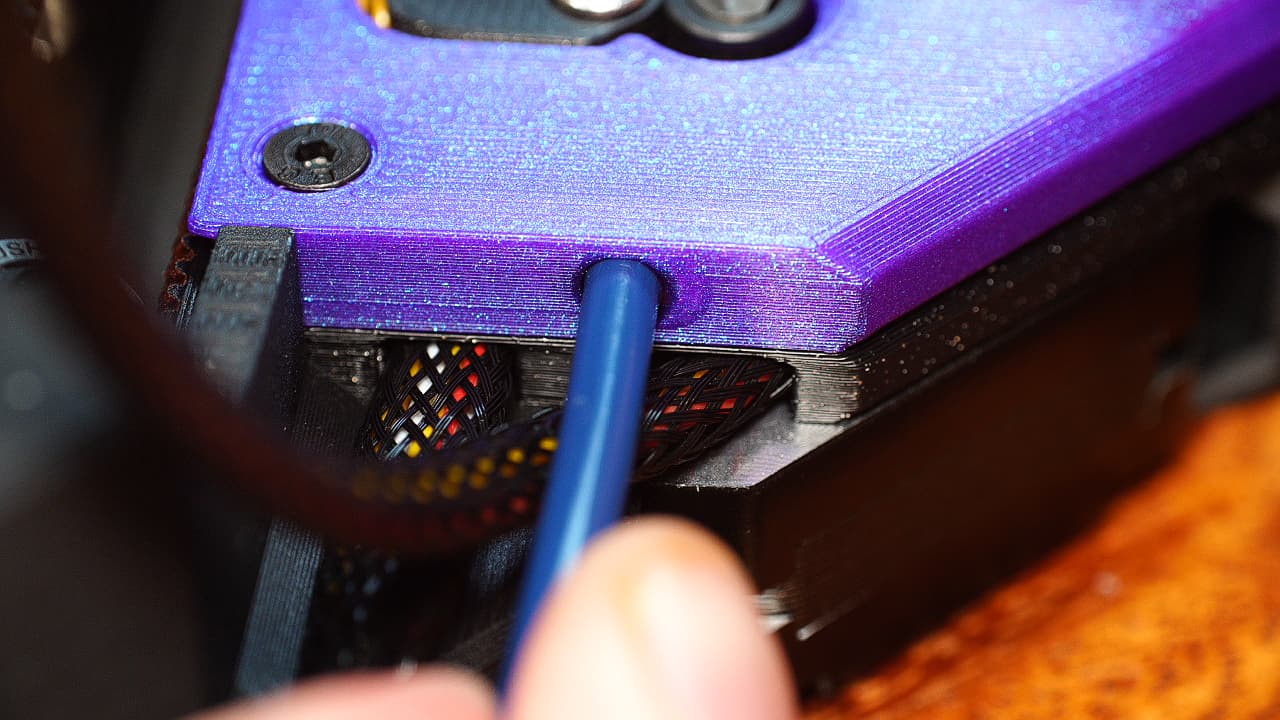

Insert the bowden tube

Insert the bowden tube into the top plates. There is a lot of clearance, so the glue will go all the way down.

Insert the bowden tube into the top plates. There is a lot of clearance, so the glue will go all the way down. -

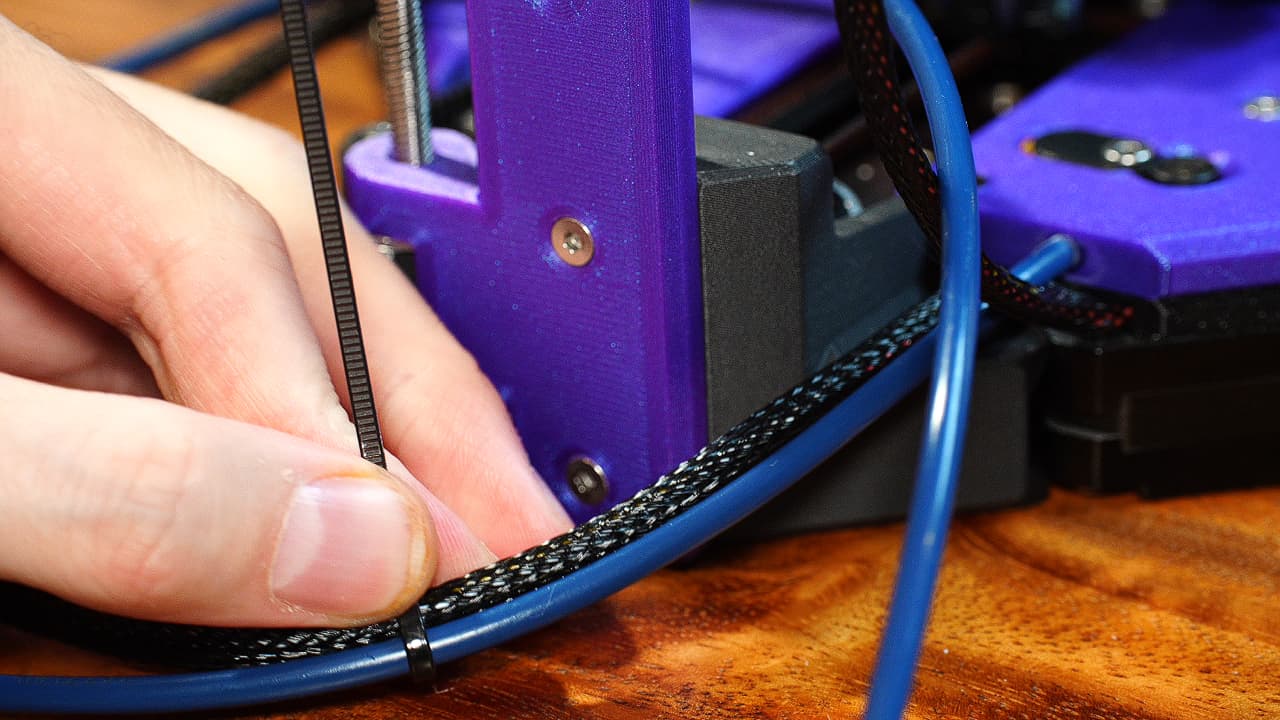

Zip tie the bowden tube

Zip tie the bowden tube with 2 zip ties, one at 10cm, another at 20cm.

Zip tie the bowden tube with 2 zip ties, one at 10cm, another at 20cm. -

Mark the bowden tube

Holding the tube approximately where it needs to go, mark the bowden tube as pictured.

Holding the tube approximately where it needs to go, mark the bowden tube as pictured. -

Cut the bowden tube

SNIP, SNIP! The end needs to be as straight as possible.

SNIP, SNIP! The end needs to be as straight as possible. -

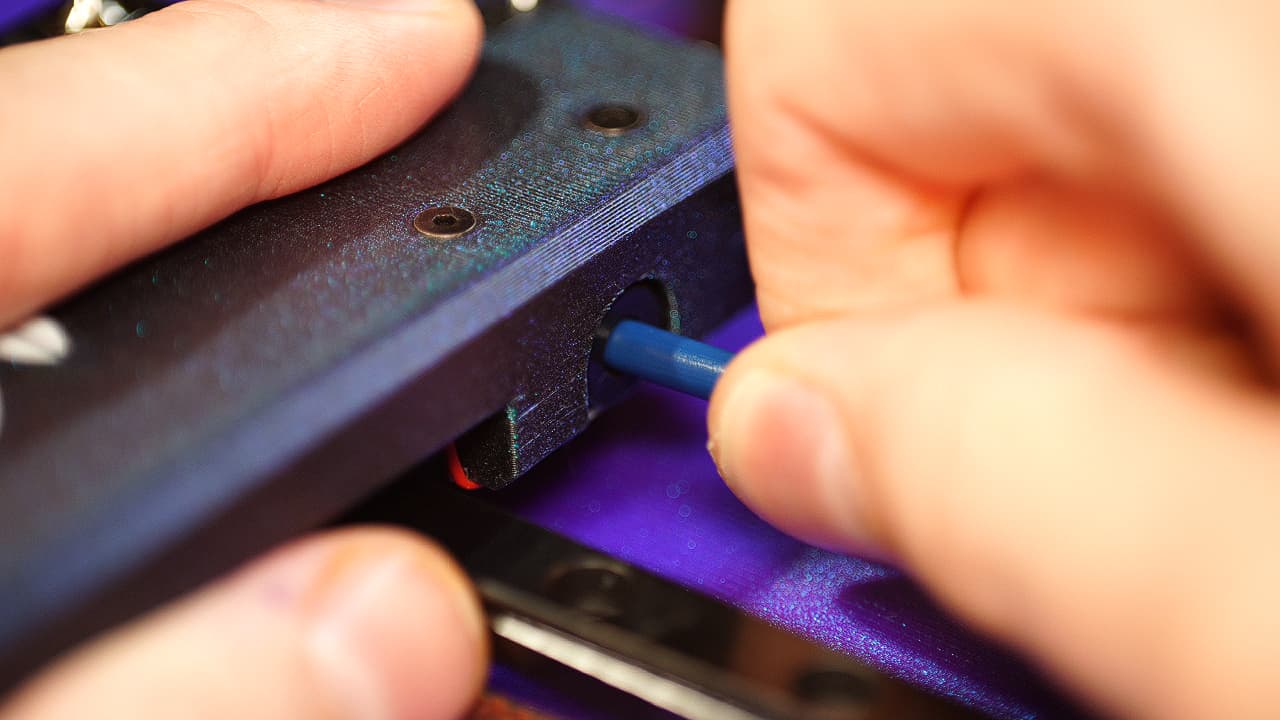

Insert bowden tube

Insert the bowden tube all the way into the tool end.

Insert the bowden tube all the way into the tool end. -

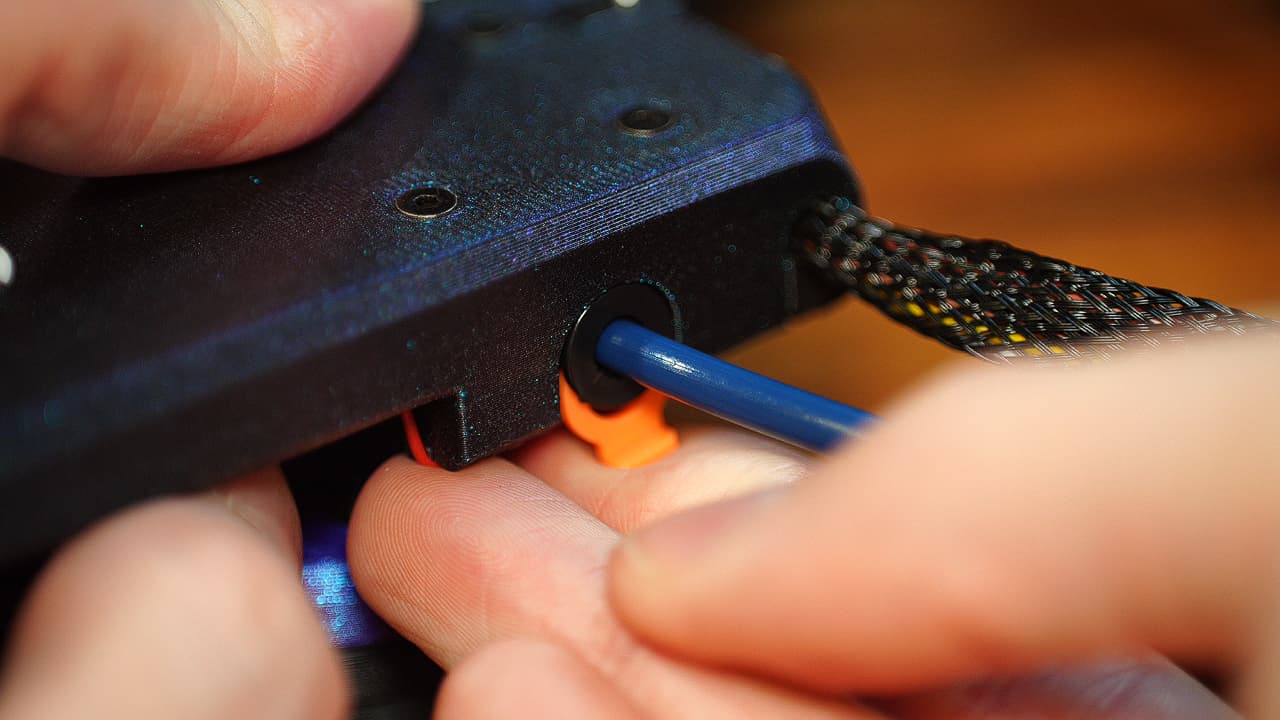

Insert the clip

While still putting pressure on the bowden tube, pull out the collar and install the orange clip.

While still putting pressure on the bowden tube, pull out the collar and install the orange clip. -

Attach the bed holder

Attach the bed holder to the Z carriage with the two captive screws.

Attach the bed holder to the Z carriage with the two captive screws. -

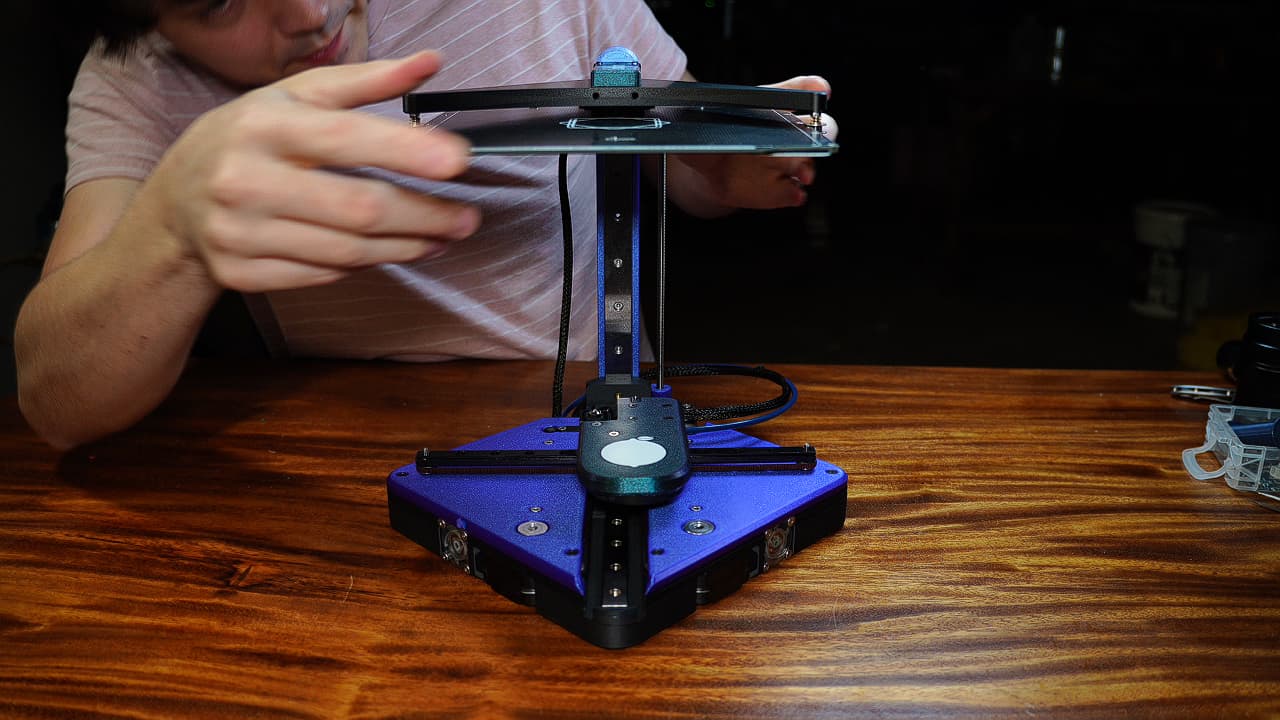

Slide in the bed

Slide the bed into the spring-loaded posts.

Slide the bed into the spring-loaded posts. -

Add the spool holder

O P T I O N A L Attach the spool holder through the unpopulated 4th hole on the Z axis.M340mmThis one is an upgraded model designed by @AngryTaco!

Attach the spool holder through the unpopulated 4th hole on the Z axis.M340mmThis one is an upgraded model designed by @AngryTaco! -

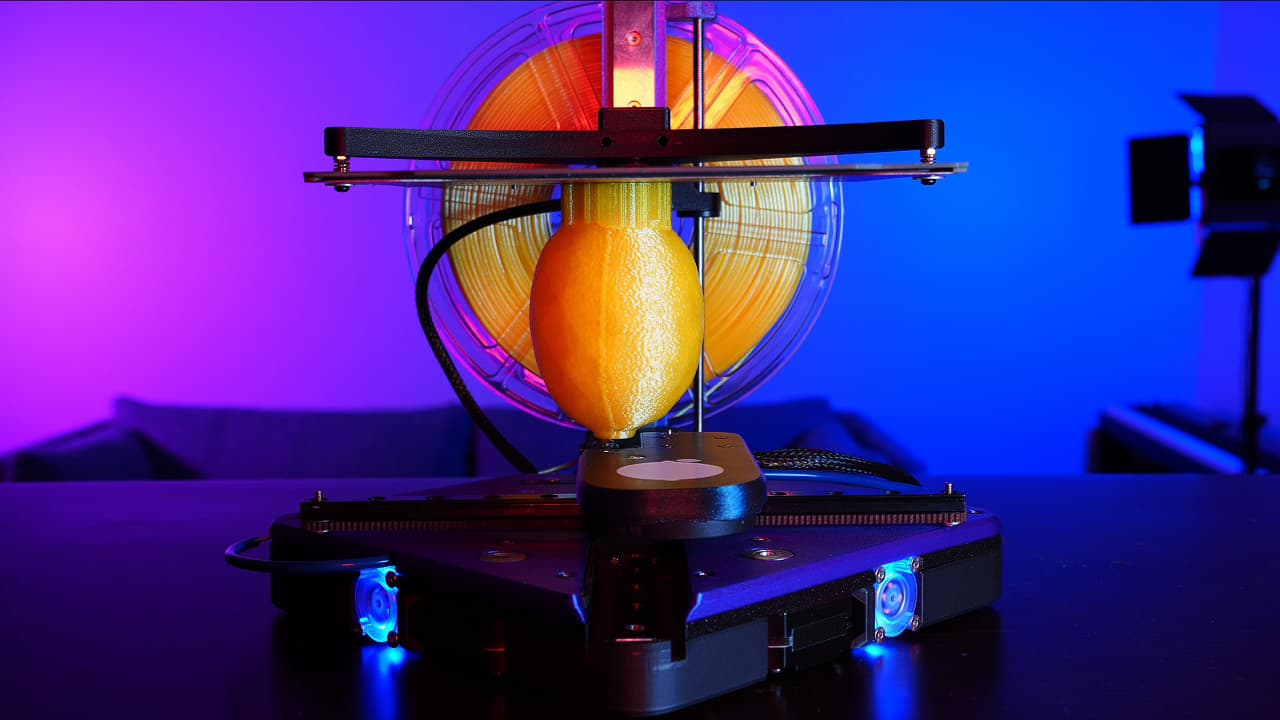

You've reached the end!

You just built the whole thing. Now wash up, you're probably covered in solder fumes.

You just built the whole thing. Now wash up, you're probably covered in solder fumes. -

Sike you've not reached the end!

Use the handy guide to do your one-time calibration.

Use the handy guide to do your one-time calibration.

Follow the old machinists tapping tip, which is to drive the screw in, back it out, and

drive it in some more, over and over. This is the best way to ensure you can reuse the plastic threads.

Note for the armchair experts who cry about ferrules

If I hear one more idiotic comment about your stupid ferrules, I will find a tiny ferrule

for your tiny benis and clamp it so hard that you'll wish I would use the iron instead.

Electrical Shock Warning

If caution is not exercised, this device has the potential to cause harm through injuries, burns, and

electrical shocks. Do not become complacent!

But loose belt? Is Lemontron a moron?

You should feel the elasticity, and you should not be able to strum the belt. Why? Because it's not CoreXY!

With only one belt and the same amount of friction total.

Surely there's a better way?

Sometimes the simple solutions are the best. With the absurd contact patch of about 2cm², the glue will hold

the tube until the end of time.