How to rebuild the Positron 90 Hotend

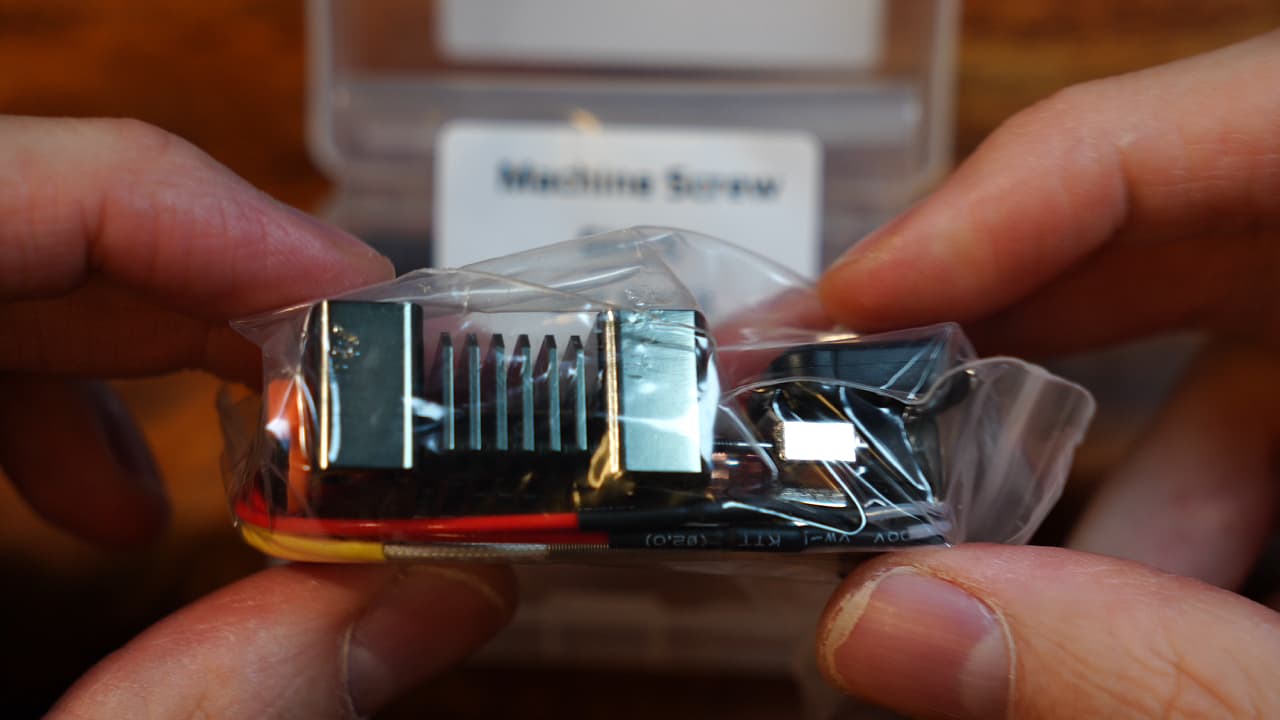

Despite its savage heat, high flow rate, solid engineering & high quality construction, there is one an issue with the Positron 90 hotend! It ships from the factory loose, causing leaking and horrible results before you tighten it up. It’s absolutely imperative that you rebuild the hotend before you use it.

-

Remove retaining screw

Remove the M2.5 screw that retains the thermistor & sock.

Remove the M2.5 screw that retains the thermistor & sock. -

Remove the sock

Pull off the sock.

Pull off the sock. -

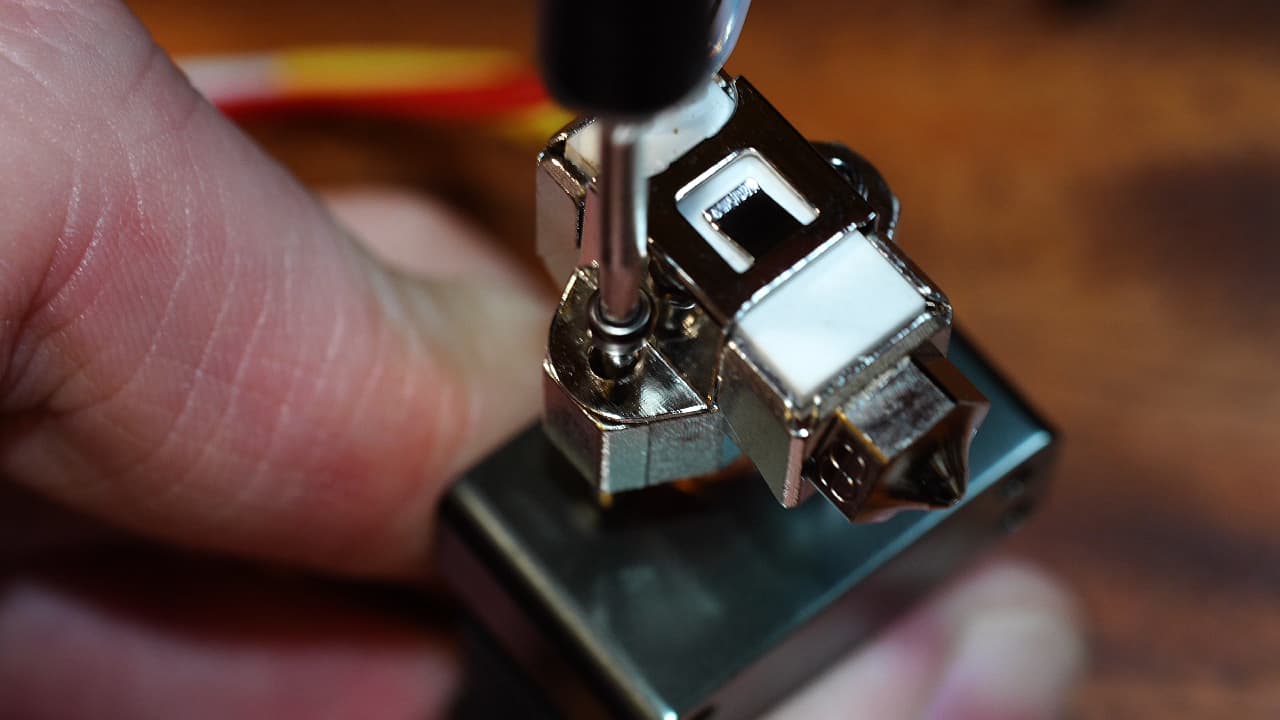

Remove the clip

Unscrew the screws holding on the clip.

Unscrew the screws holding on the clip. -

Remove the heater

Fully remove the heater and clip.

Fully remove the heater and clip. -

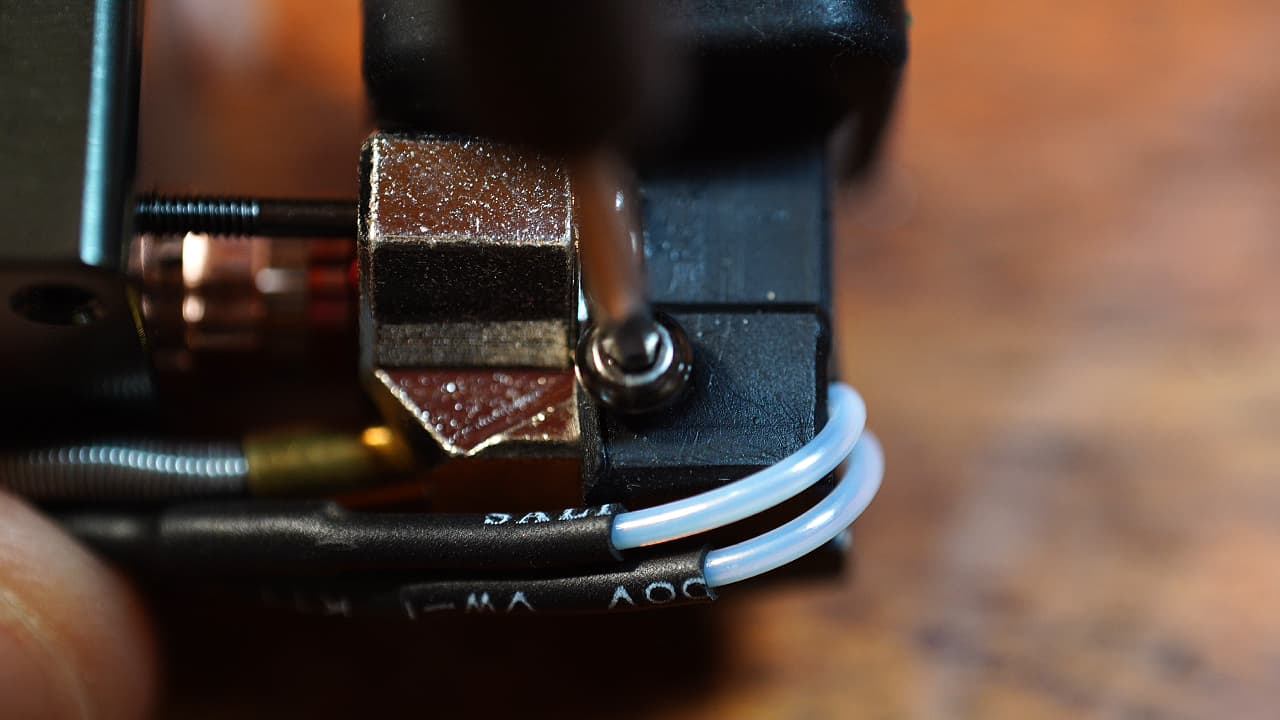

Pull out the thermister

It will slide out without force.

It will slide out without force. -

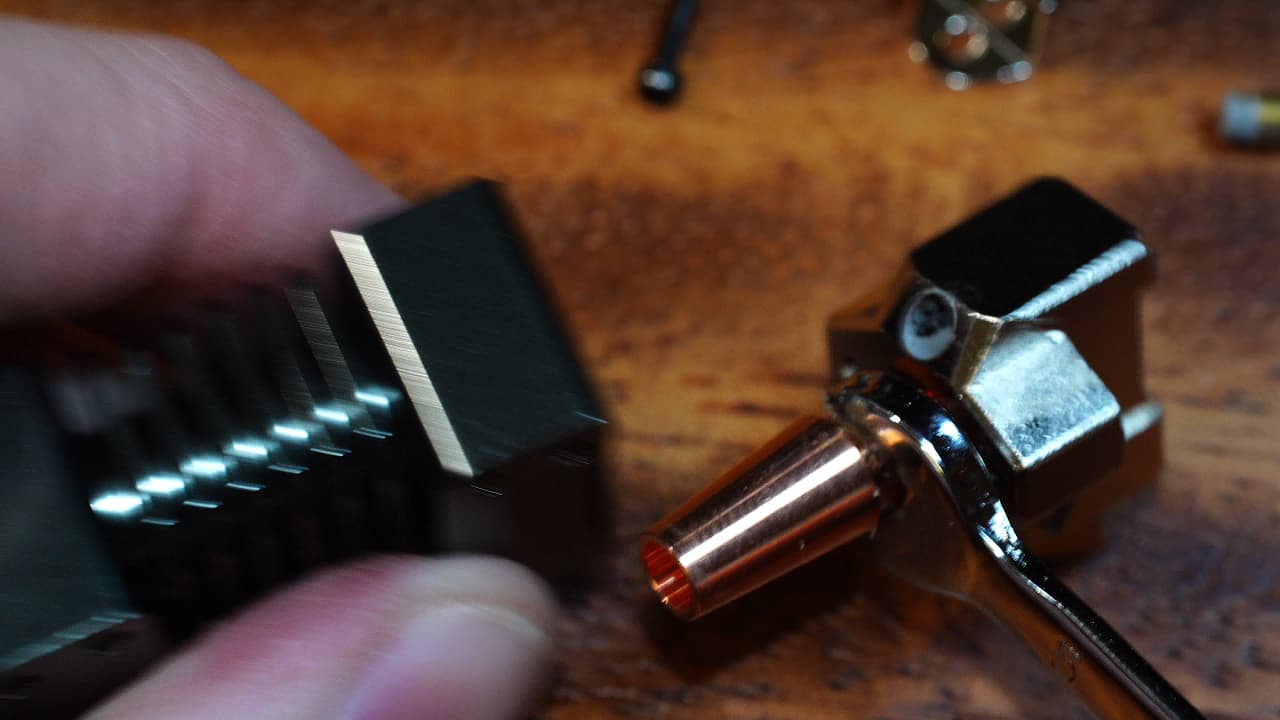

Pull out the heat break

This weird cone-shaped copper bimetallic heat break is quite amazing.

This weird cone-shaped copper bimetallic heat break is quite amazing. -

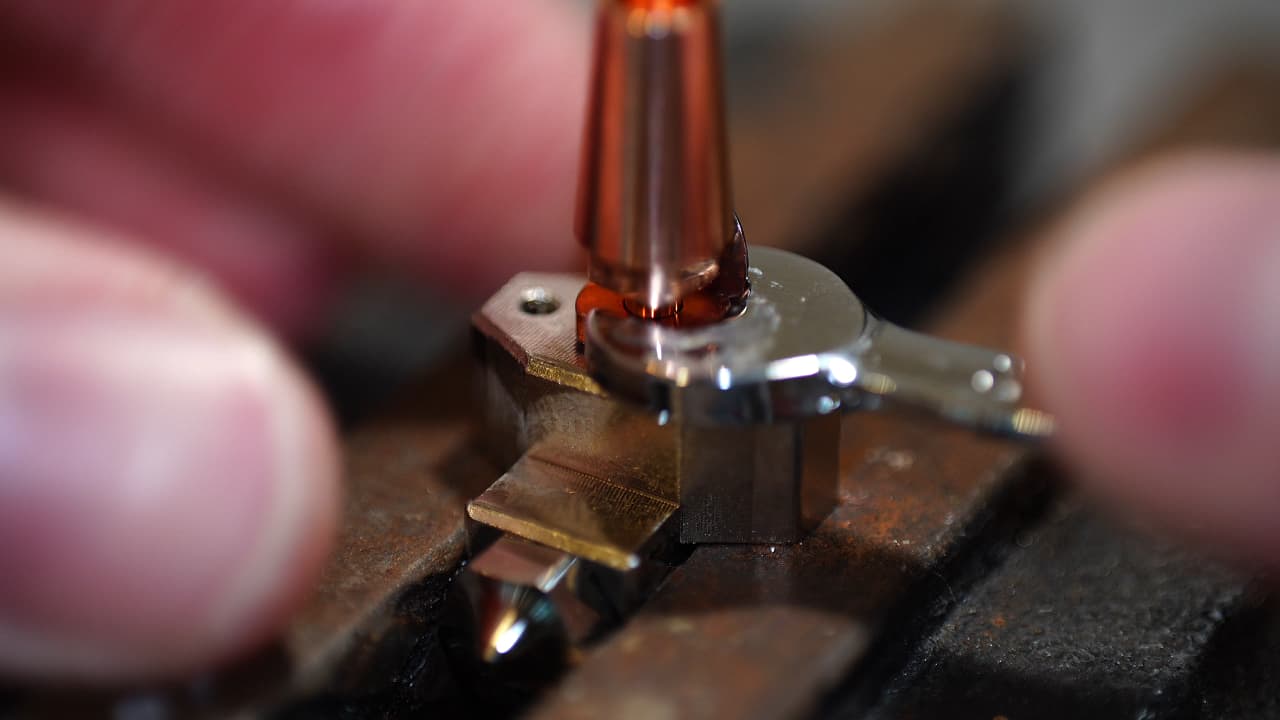

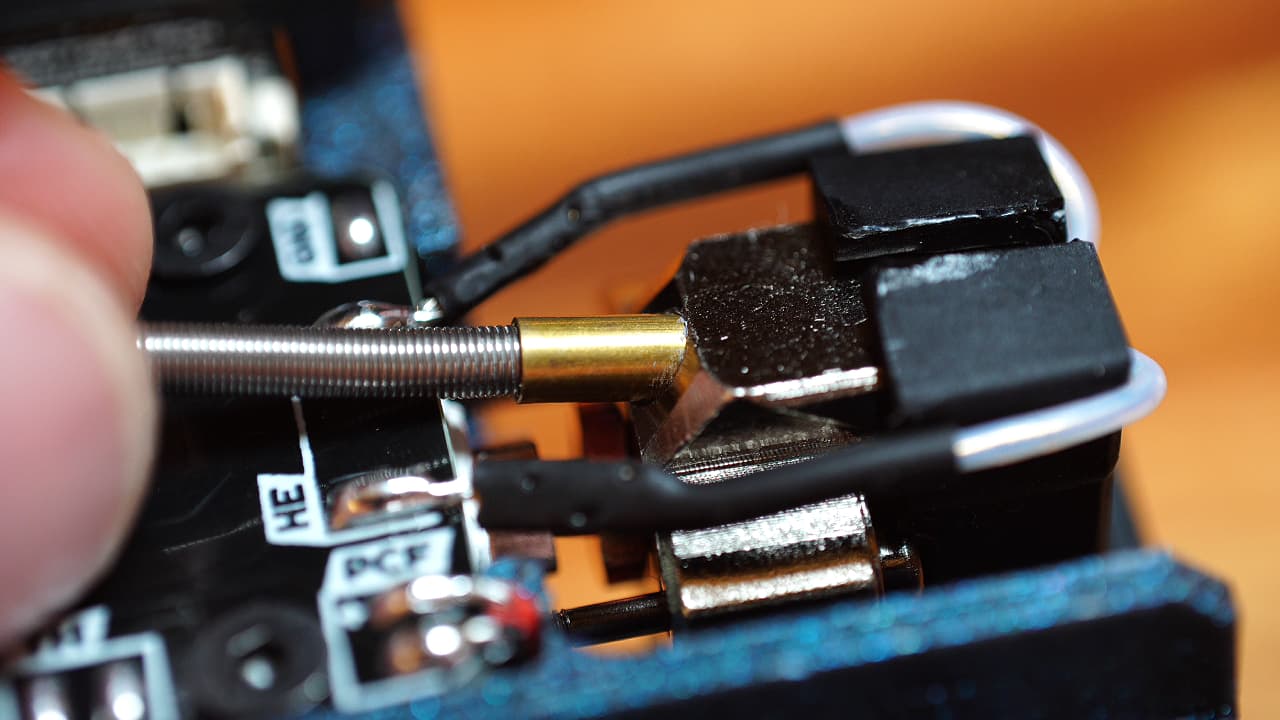

Tighten the heat break

Using a 5mm wrench, tighten the heat break carefully! The heat break is copper (a ductile material). I had to shim the wrench with a 0.2 shim to avoid mangling it.

Using a 5mm wrench, tighten the heat break carefully! The heat break is copper (a ductile material). I had to shim the wrench with a 0.2 shim to avoid mangling it. -

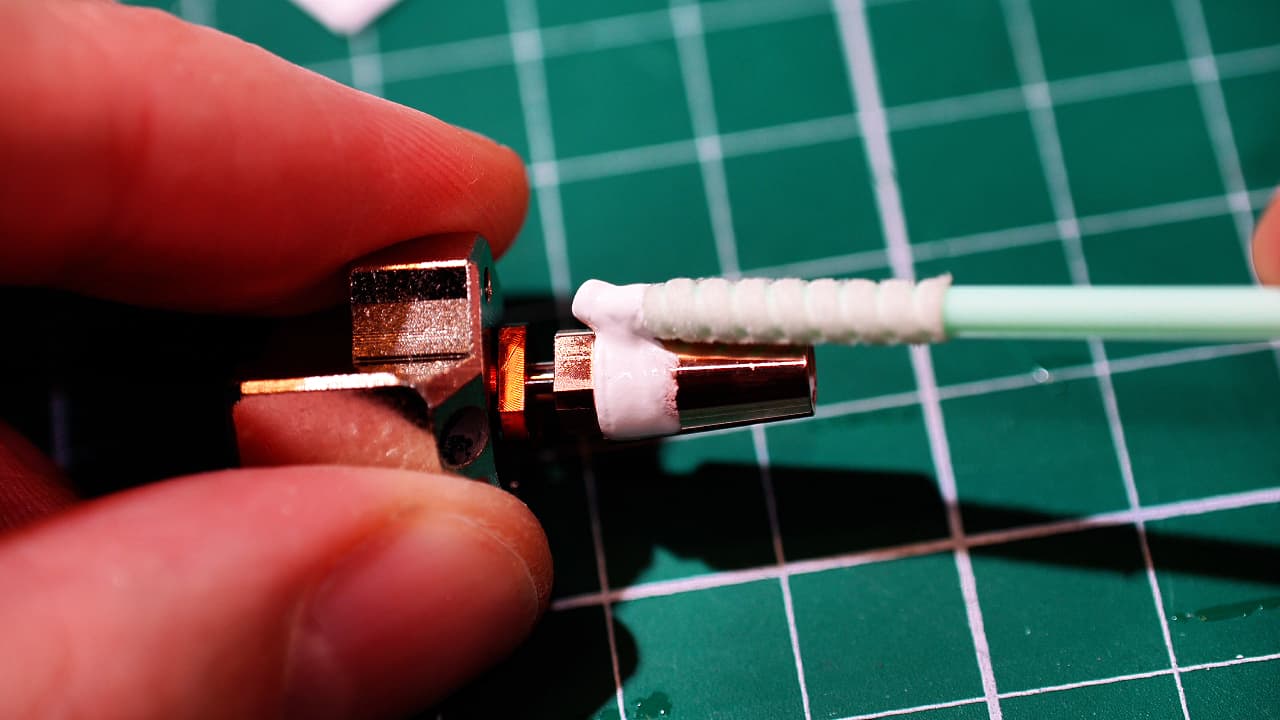

Apply boron nitride to the heat break

O P T I O N A L This is completely optional! Don't feel bad if you don't do it, I just can't resist while it's torn down.

This is completely optional! Don't feel bad if you don't do it, I just can't resist while it's torn down. -

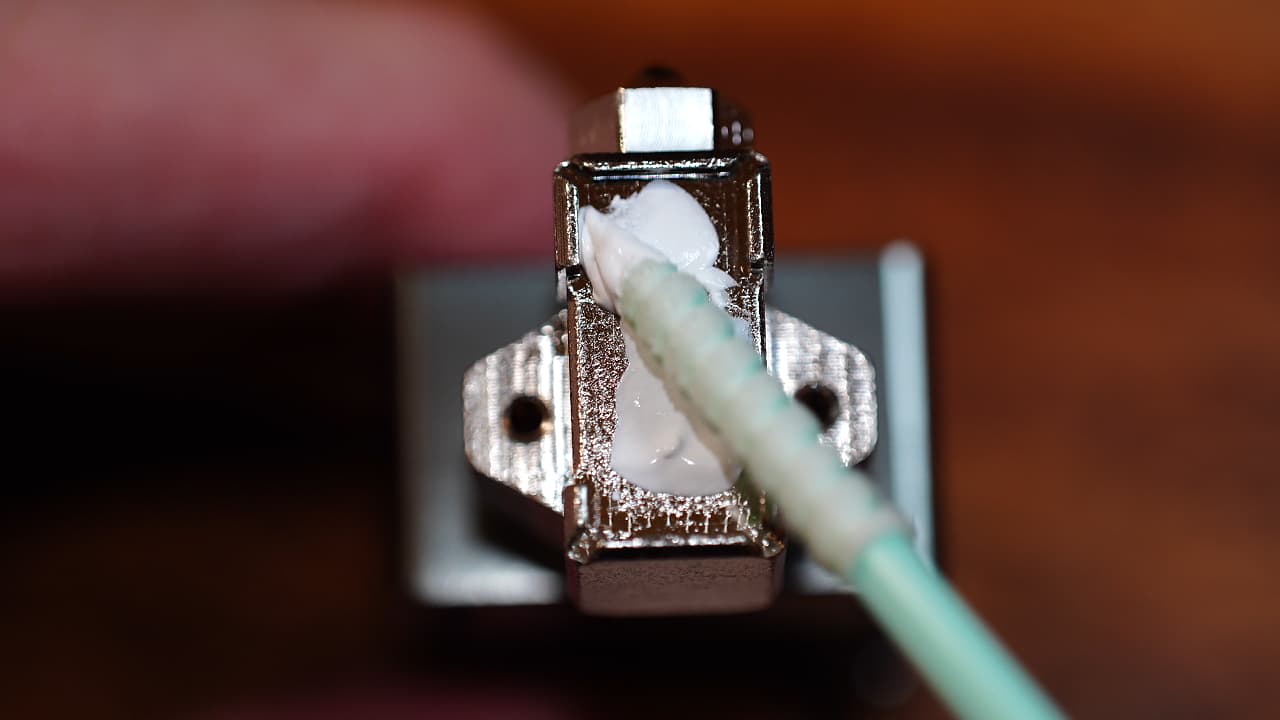

Apply boron nitride to the heater

O P T I O N A L Also completely optional. I am told that the heat transfers fine without the paste.

Also completely optional. I am told that the heat transfers fine without the paste. -

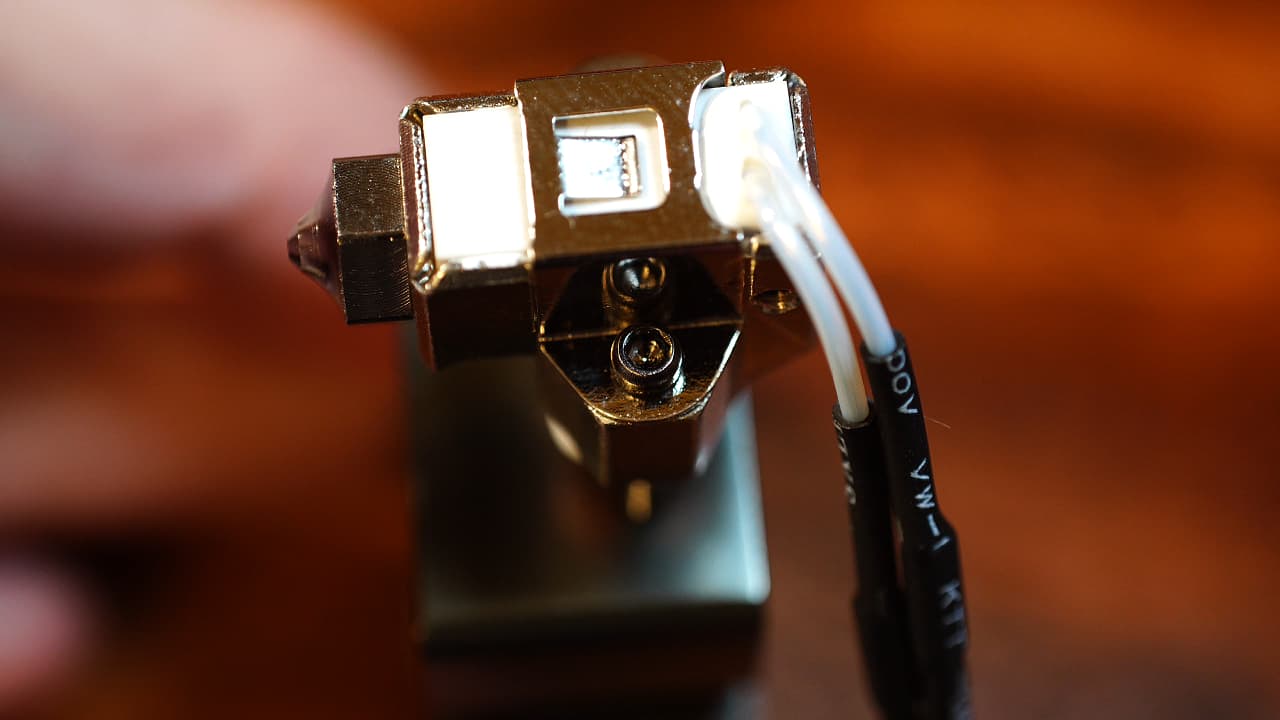

Reattach heater and clip

Reattach the heater and clip, applying equal pressure to both screws. Do not over-tighten.

Reattach the heater and clip, applying equal pressure to both screws. Do not over-tighten. -

Insert thermistor and replace sock

Reattach the thermister and sock and replace the retaining screw.

Reattach the thermister and sock and replace the retaining screw.