3d printing upside down changes nothing!

3D printing continues to evolve, and one minor development is the concept of printing upside down. I investigated this idea because it provides a way to consolidate all the heavy components near the bottom.

While the idea might sound unconventional, the actual printing experience remains the same. “But Lemontron”, you say, “ shouldn’t the effects of gravity cause some noticeable difference”?

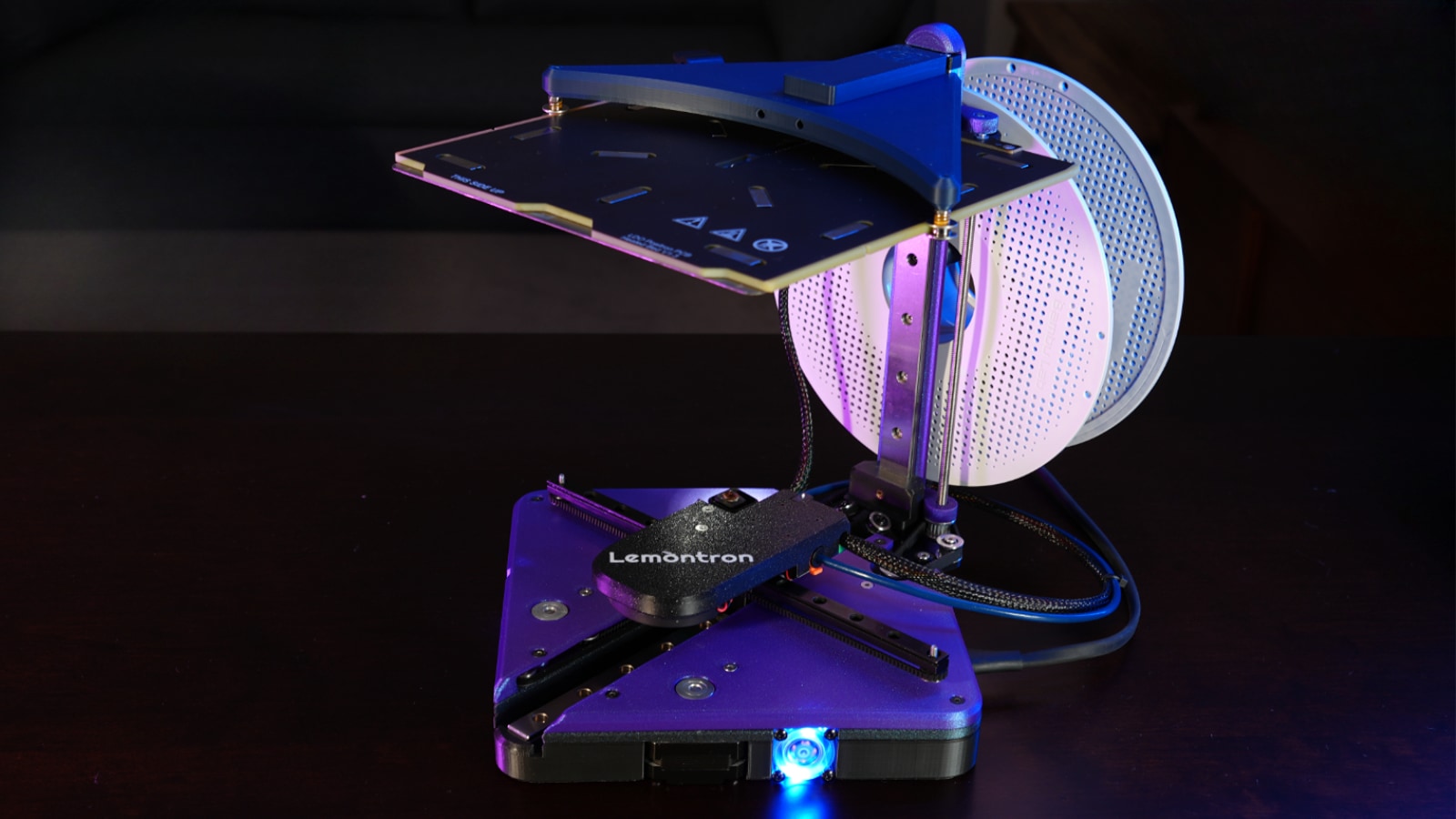

In Positron-style 3D printers like the V3.2, JourneyMaker, and Lemontron, this design is realized fully, and despite the orientation, the fundamental principles of 3D printing remain the same. The printer still follows the sliced model data layer by layer. The gravitational effects on the molten material are minimal because it solidifies almost instantly upon extrusion, whether it’s oriented upwards or downwards. You can even try this on any printer, go ahead and flip yours while it prints, you’ll see it doesn’t care!

Supports Constrain Molten Filament, Not Defy Gravity

A common misconception in 3D printing is that supports are primarily needed to prevent parts of the print from sagging or collapsing under gravity. In reality, supports are there to constrain the movement of molten filament during printing. When extruded, the filament is in a semi-liquid state and needs something to adhere to for accurate placement. Supports provide a temporary scaffold that guides the filament, ensuring it solidifies in the correct position.

This understanding also clarifies why printing upside down doesn’t negate the need for supports. Since the primary role of supports is to provide a foundational surface to adhere to rather than to combat gravity, their function remains crucial regardless of the print orientation. Overhangs and bridges still require supports to maintain structural integrity during the printing process.

Completely Familiar Workflow

Preparing models for printing upside down doesn’t change anything. The slicing software and settings for layer height, print speed, and temperature remain consistent with those of standard printers. The calibration process is familiar too—leveling the build plate, checking nozzle distances, and ensuring proper adhesion are all part of the routine.

One might think that printing upside down could introduce issues with layer adhesion or print stability, but in practice, these concerns are negligible. Materials do bond effectively regardless of orientation.

Conclusion

In essence, printing upside down offers nothing notable in terms of advantages or disadvantages. Understanding that supports are meant to constrain molten filament rather than solely counteract gravity highlights how fundamental 3D printing principles apply universally, regardless of orientation. At the end of the day, what orientation you printed a part in is barely a footnote, which is kind of the whole point!

Overall, it’s a testament to the proper engineering and elimination of variables that such variations can exist without complicating the process. If you come in doubting upside down printing, I can just say you are the one printing upside down!