Download & print settings guide

Don't forget to scale all the ABS parts to ~100.5%!

- Supports? What supports? Lemontron does not use supports!

- To ensure dimensional accuracy, use a 0.2mm layer height and a 0.4mm nozzle.

- Top & bottom layers: To avoid infill on 1mm thick vertical features like the top plates, ensure your are using 5 top layers and 5 bottom layers.

- For an insanely buffed printer, use 50% Grid Infill and 8 Perimeters, and dial back according to your preference.

- Using my settings will use 800-1000g of filament.

- Most parts have orientations implied by the teardrop holes. Always refer to the plated file if unsure.

Chassis Inventory & Materials

-

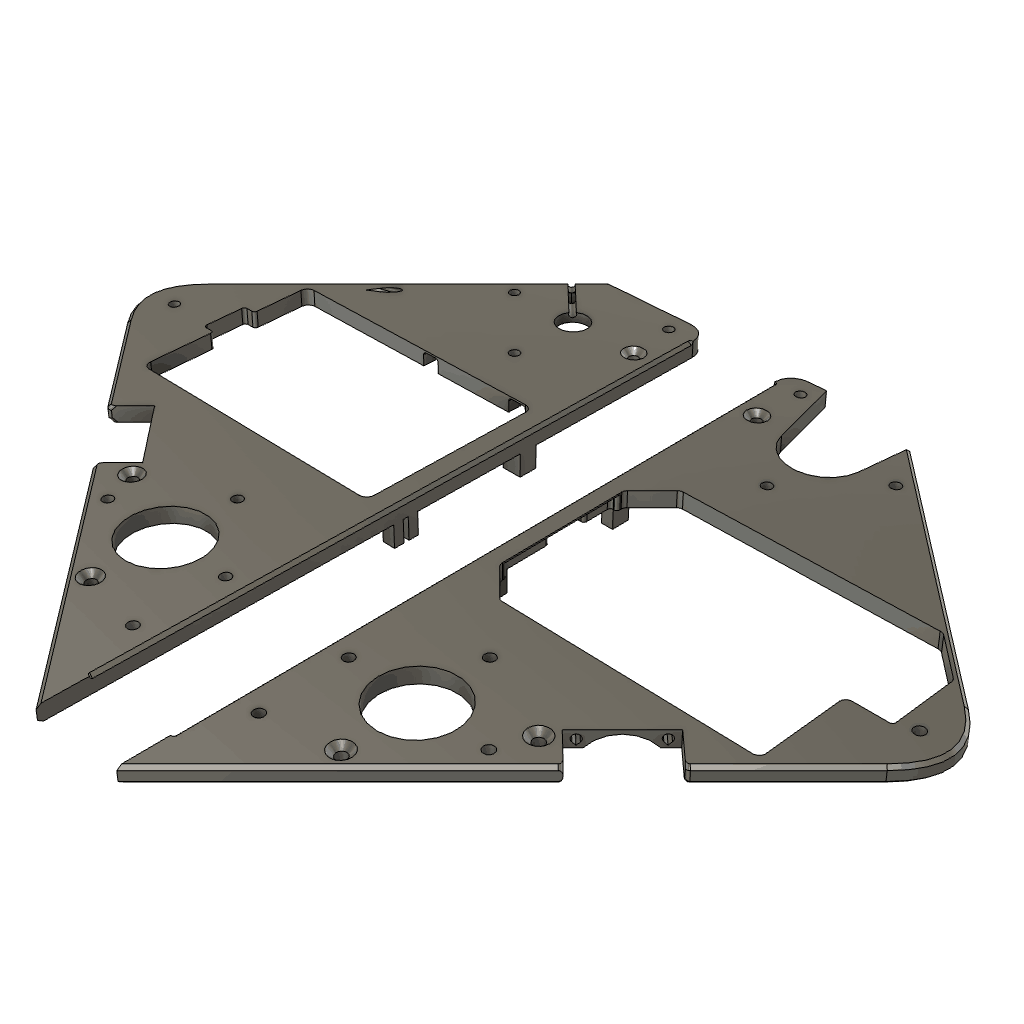

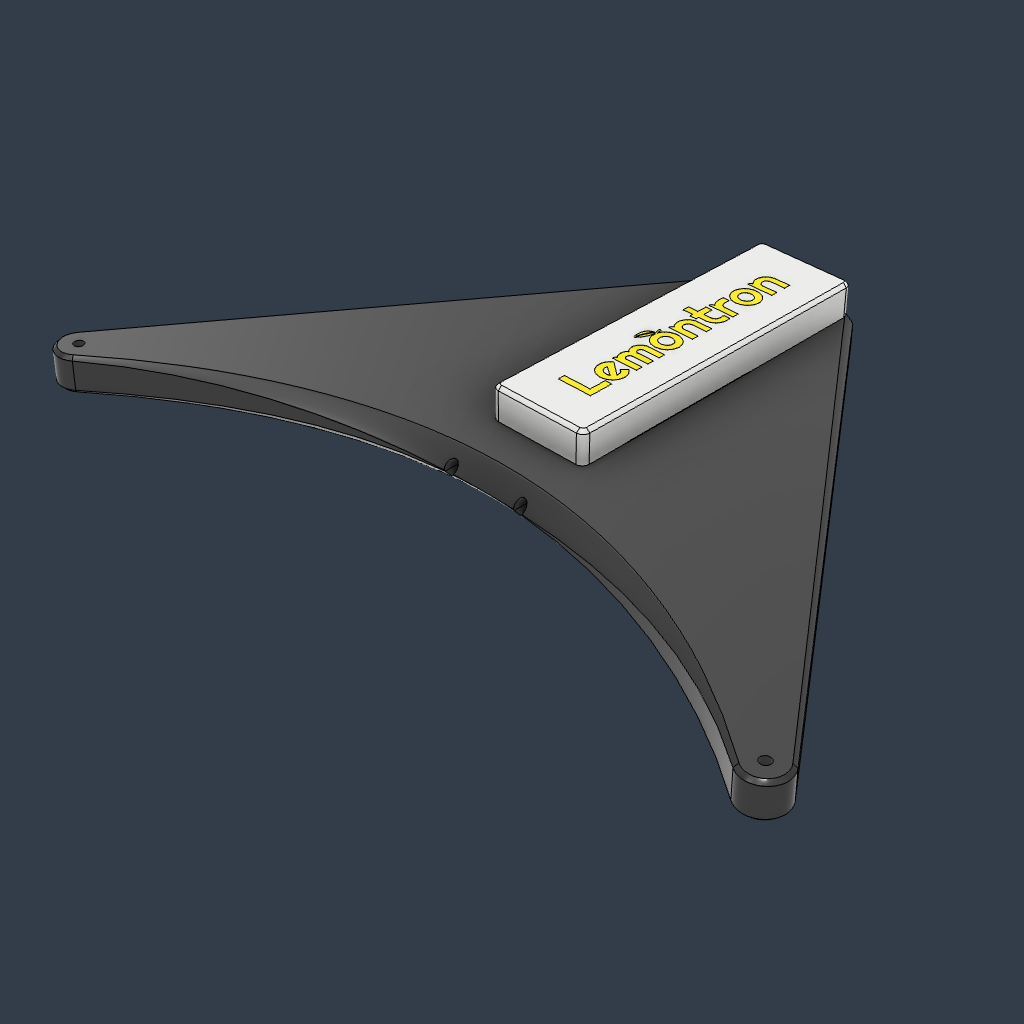

Top Plates

The top plates are mostly decorative, save for the Lemonstruder. Show off your printing abilities with a flashy filament and upload your results to the photo album. -

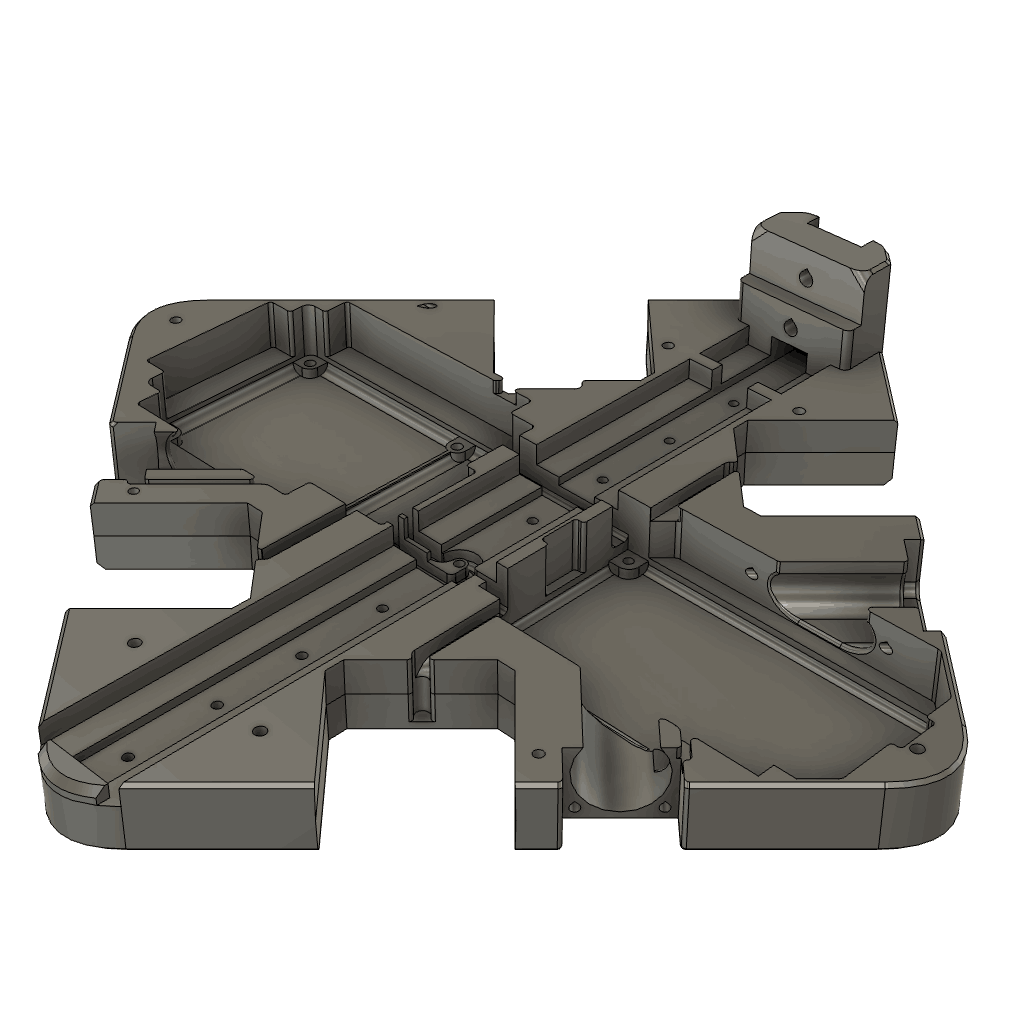

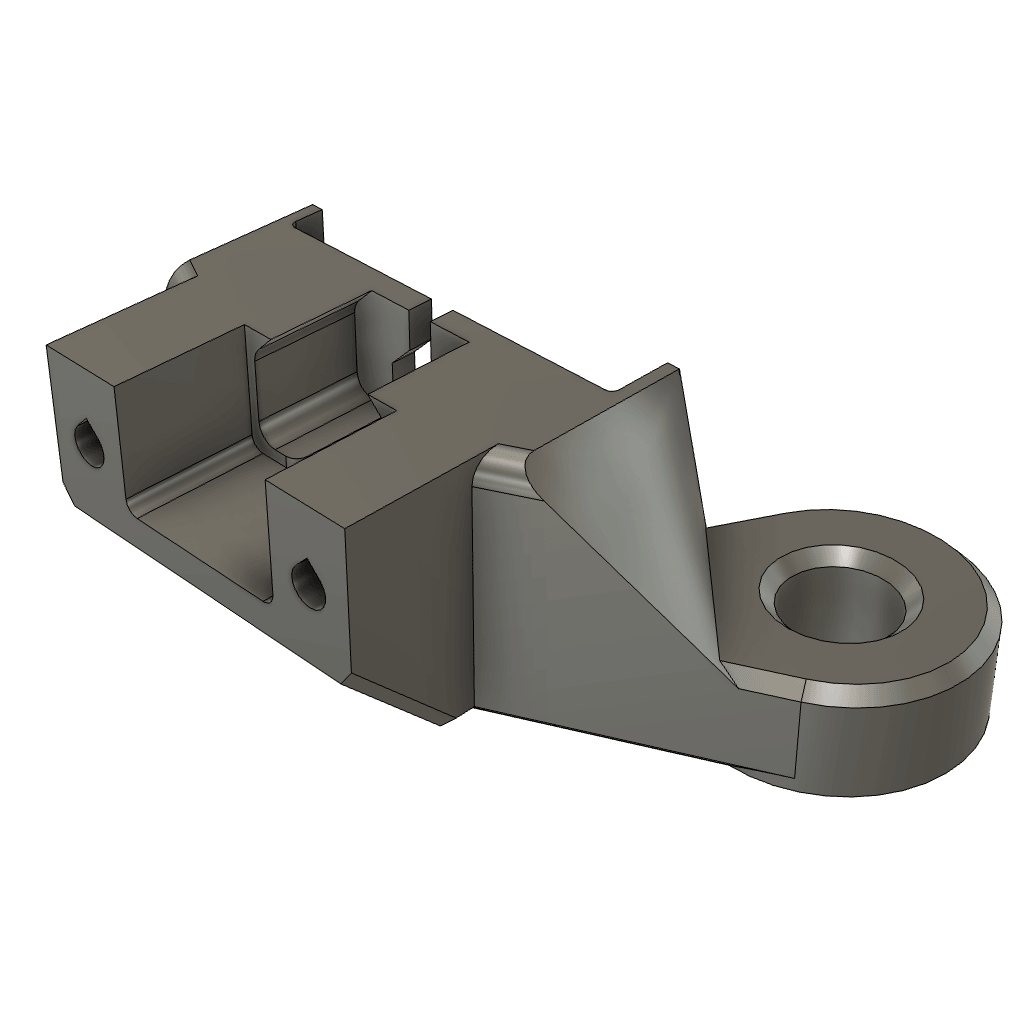

Unibody Chassis

The chassis should be made from a stiff material, and it does not experience savage heat. Therefore I would recommend PLA. -

Mid Plates

high temp material is required because these serve as the motor mounts. -

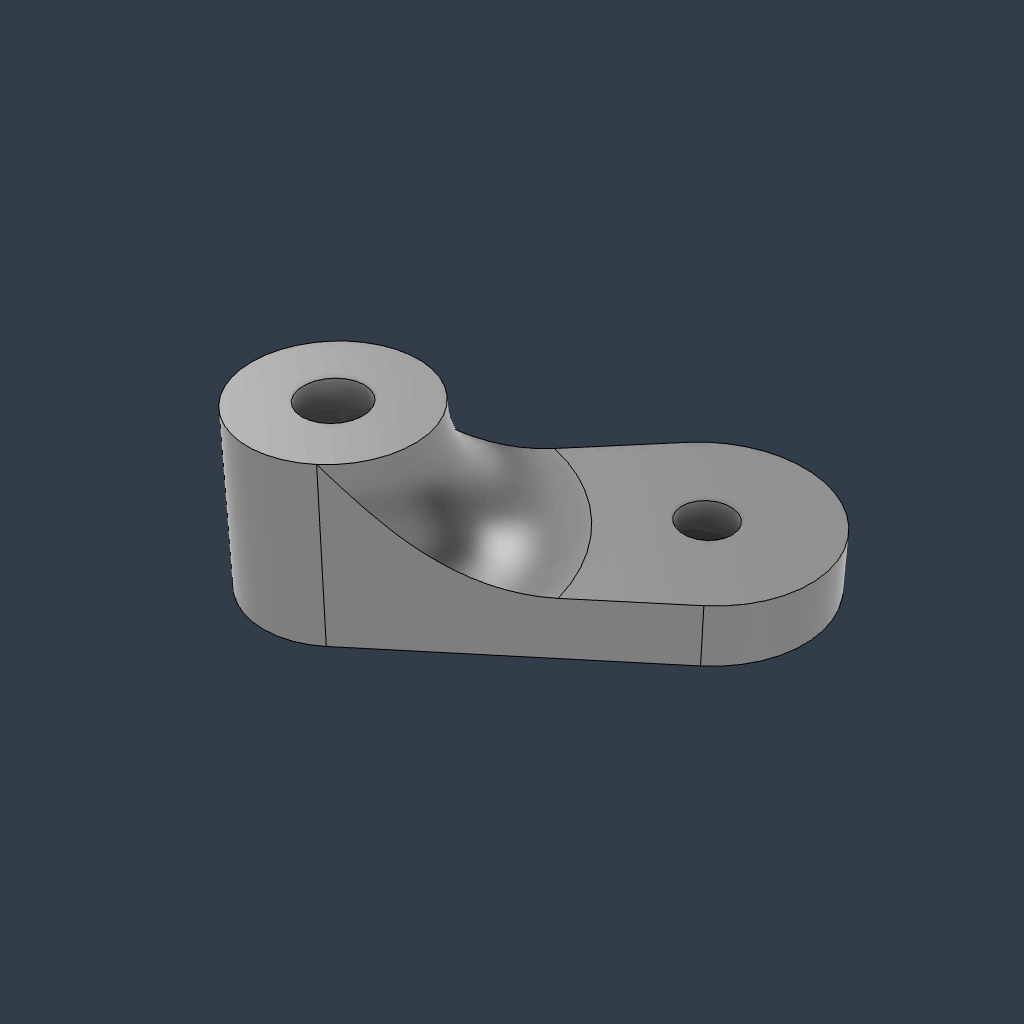

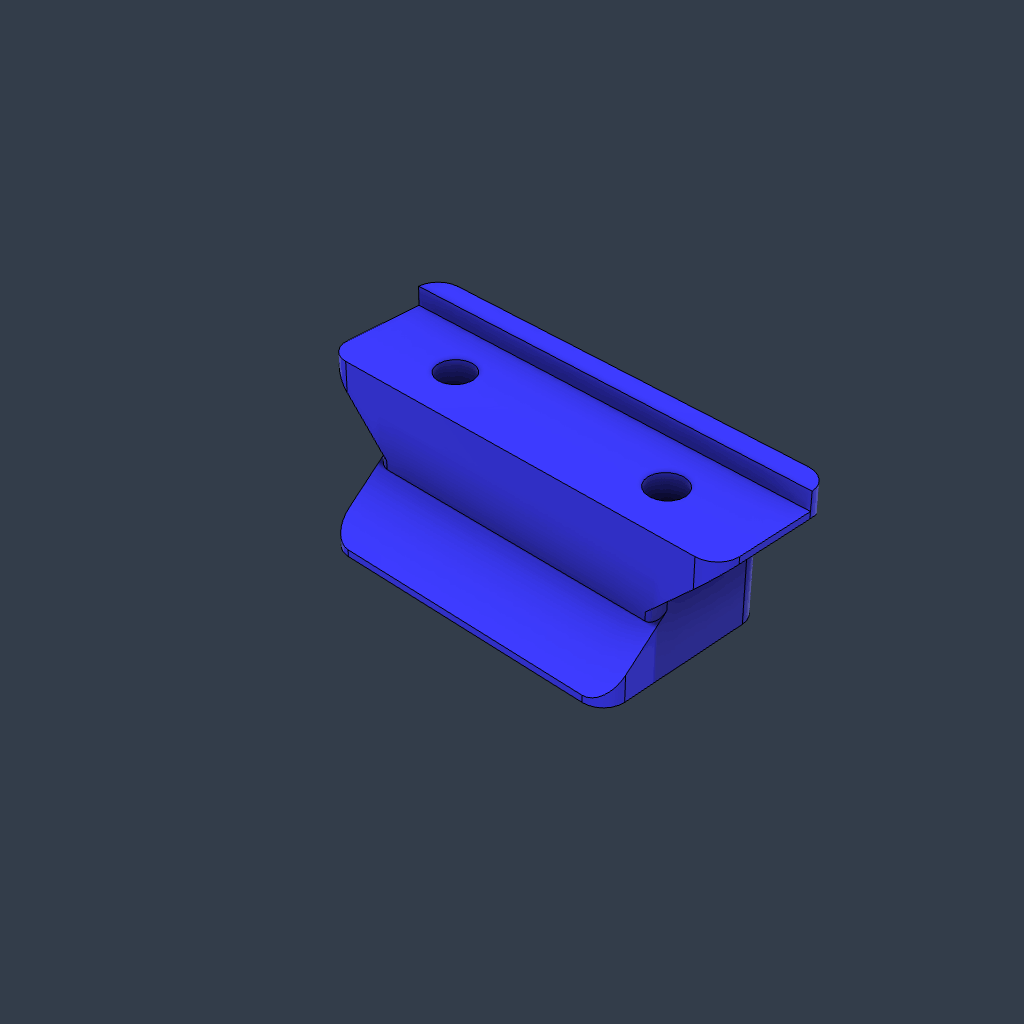

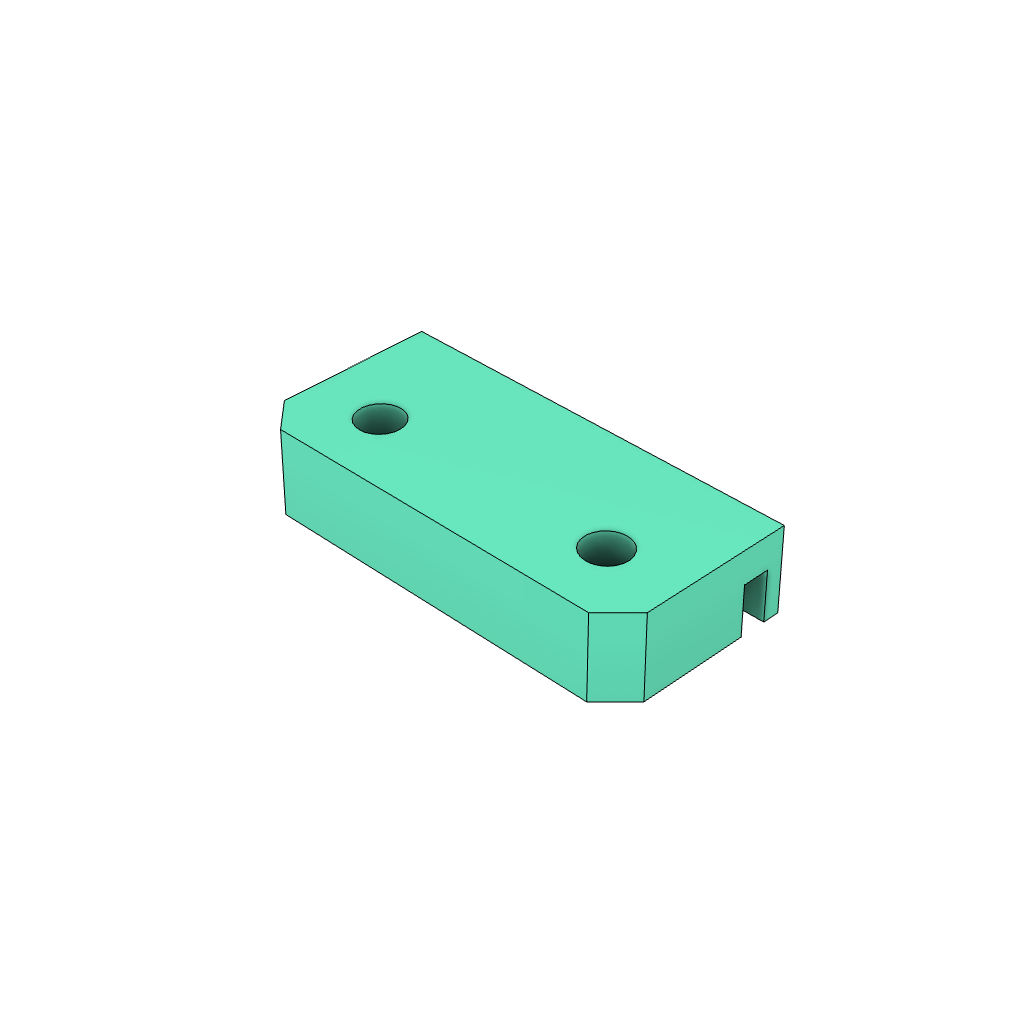

Tensioner

The tensioner experiences some torsion, so a drift-resistant material like CF-PETG is recommended. -

Lemonstruder

Lemonstruder is made of two parts. It experiences compression from the spring, so a drift-resistant material with good dimensional accuracy is preferred. -

Risers

Raspberry Pi mounts to these and they keep the SKR Pico pinned down. The material doesn't matter. -

Z-Tensioner

Does not experience much load, but does experience heat from the motor, so ABS is recommended. -

XY-Spacer

This links the X and Y rails together to create the XY plane. A stiff material, resistant to warping and drift, would be ideal like CF-PETG.

Z-Axis Inventory

-

Z-Axis

Choose any material for this part, just make sure it looks awesome. -

Bed Bracket

The bed bracket is made from two parts. A stiff material like CF-PETG would be ideal. -

Bed Holder

This is best printed in CF-PETG and the spine can be printed in whatever you want, I recommend matching the tool head materials. -

Spool Holder

This has a captive nut, so make sure to add a pause! Layer adhesion is important here, so PLA is a good choice.

Tool Head Inventory

-

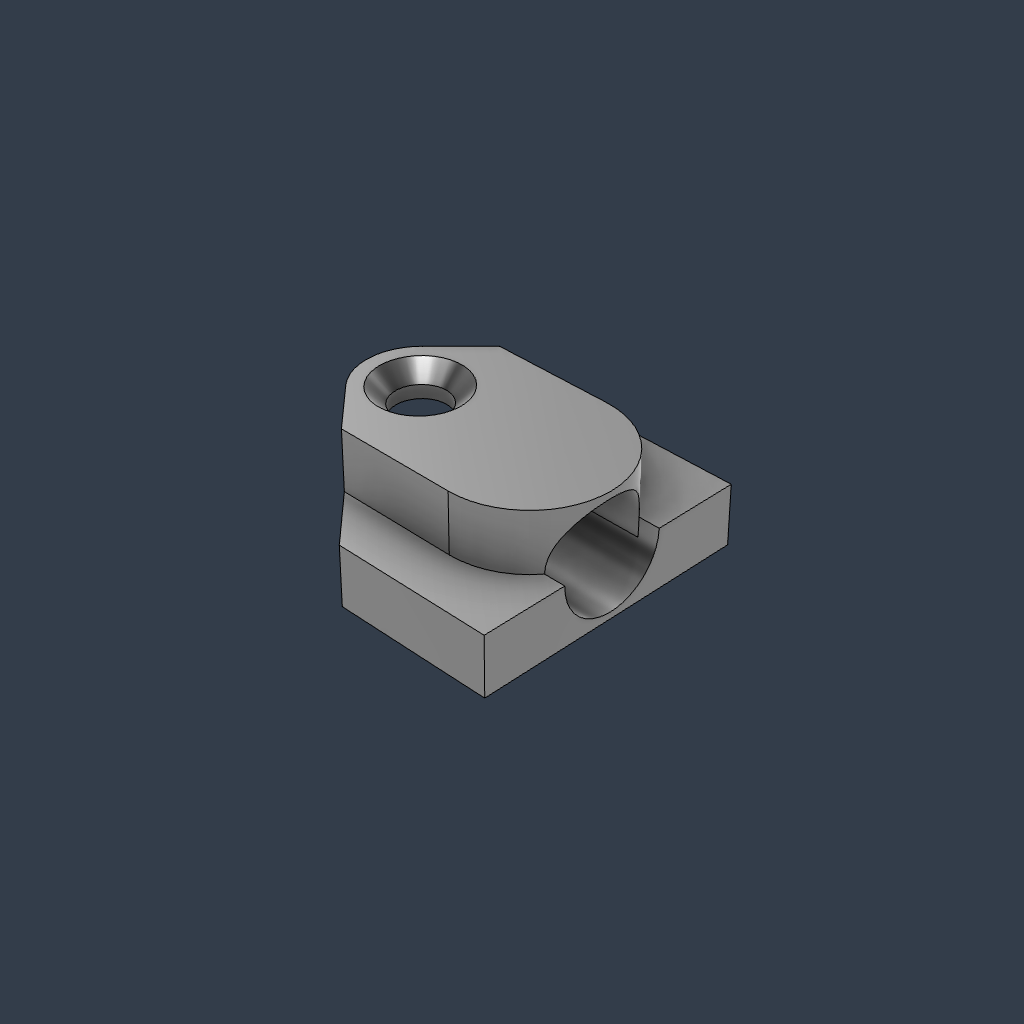

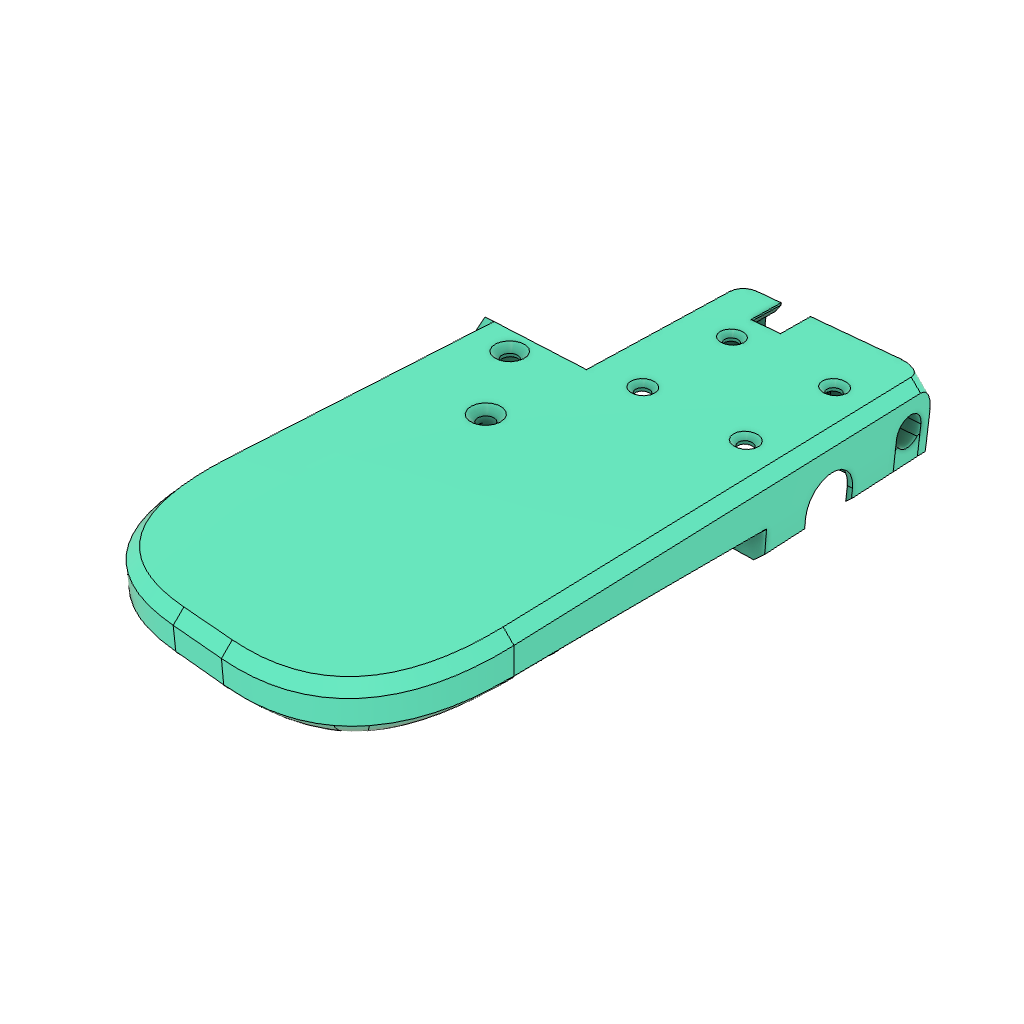

Tool Head & Clamp

The tool head houses the hotend and thus must be printed in ABS. The clamp is a small part that holds the wires in. -

Clip

Clips the belt to the tool end. Layer adhesion matters most, so I recommend PETG or PLA.