0.2mm Layer Height + 0.4mm Nozzle

Everything was designed with these feature sizes in mind.

5 Top Layers + 5 Bottom Layers

To avoid infill on 1mm thick vertical shell thickness and provide thickness around screw holes.

Arachne-only Walls

Some features are too small to recreate with ancient technology.

Don't forget to set shrinkage for ABS/ASA!

Calibrate with a test cube; Shrinkage can be found in the filament settings of OrcaSlicer.

Printing difficulty: Level 10

This bad boy requires a recent enclosed printer or tuning that’s considered perfection-seeking! These tolerances are tight and print quality must be off-the-charts high. As for the actual assembly, the difficulty is much more forgiving– the tools are common and the build process is extremely rewarding.

Chassis Inventory & Materials

-

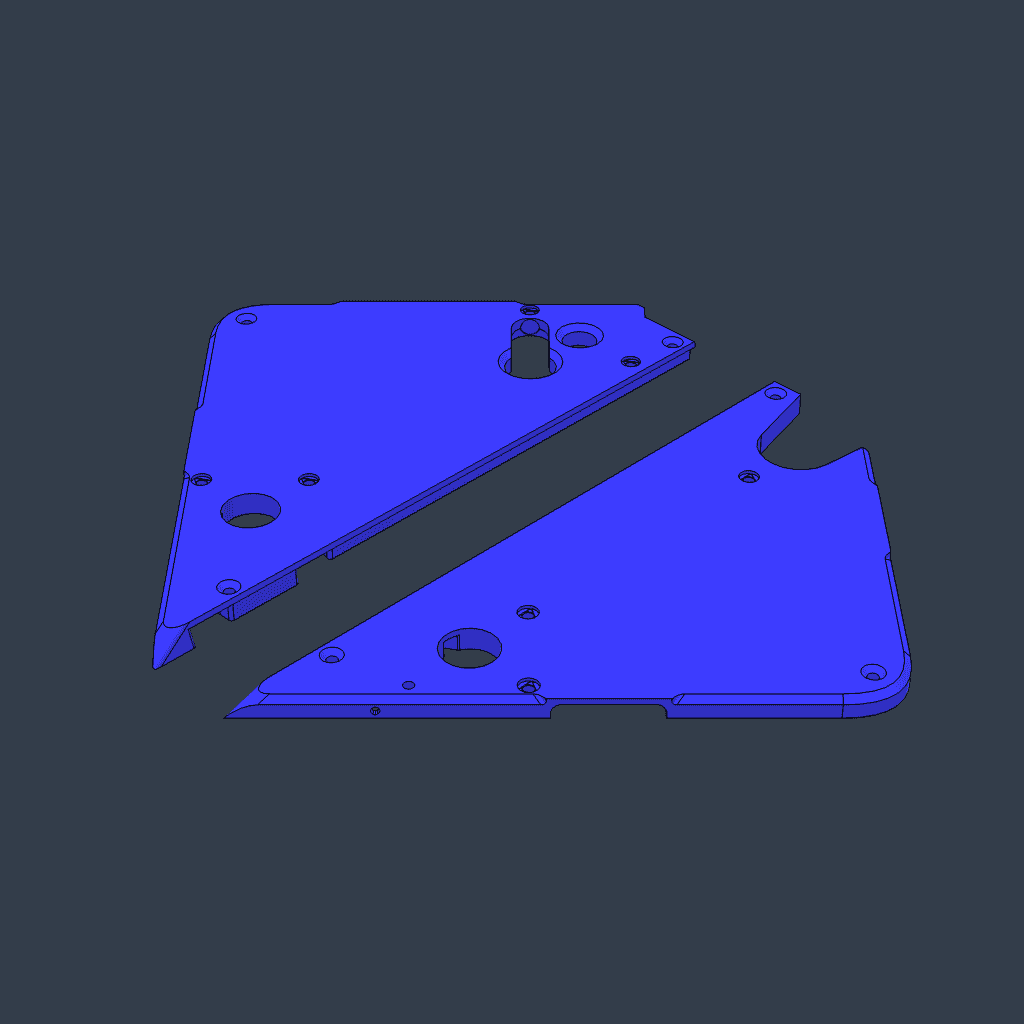

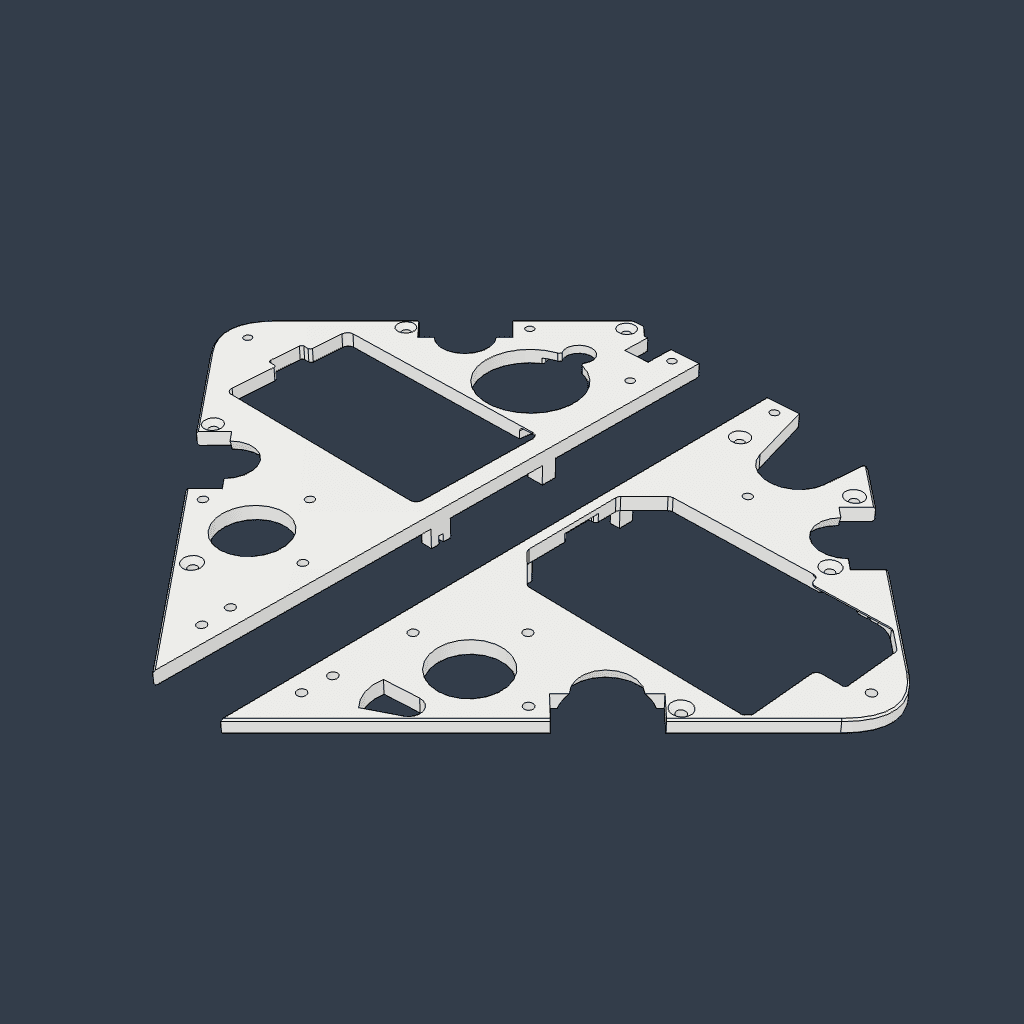

Top Plates

Mostly decorative, but need some thickness around the screw holes. Show off your printing abilities with a flashy filament.5 walls, 25% grid -

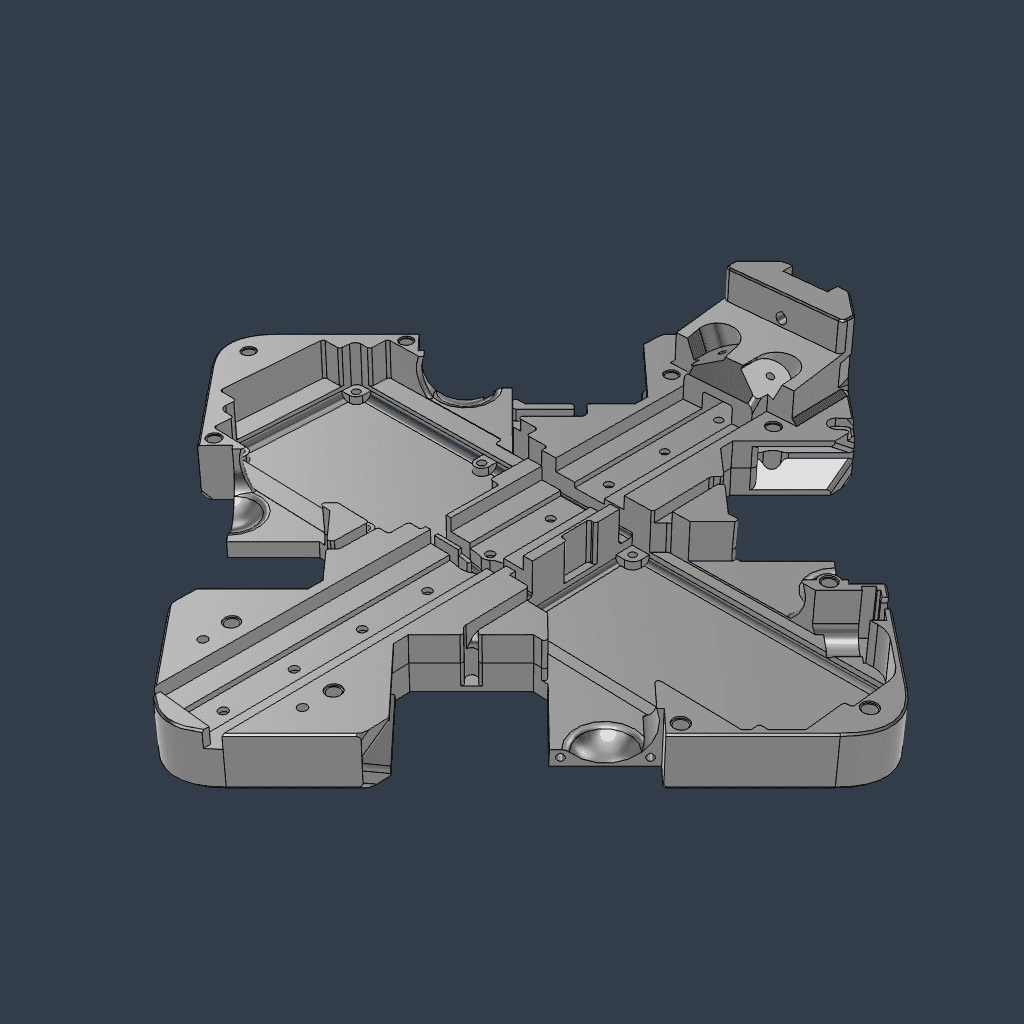

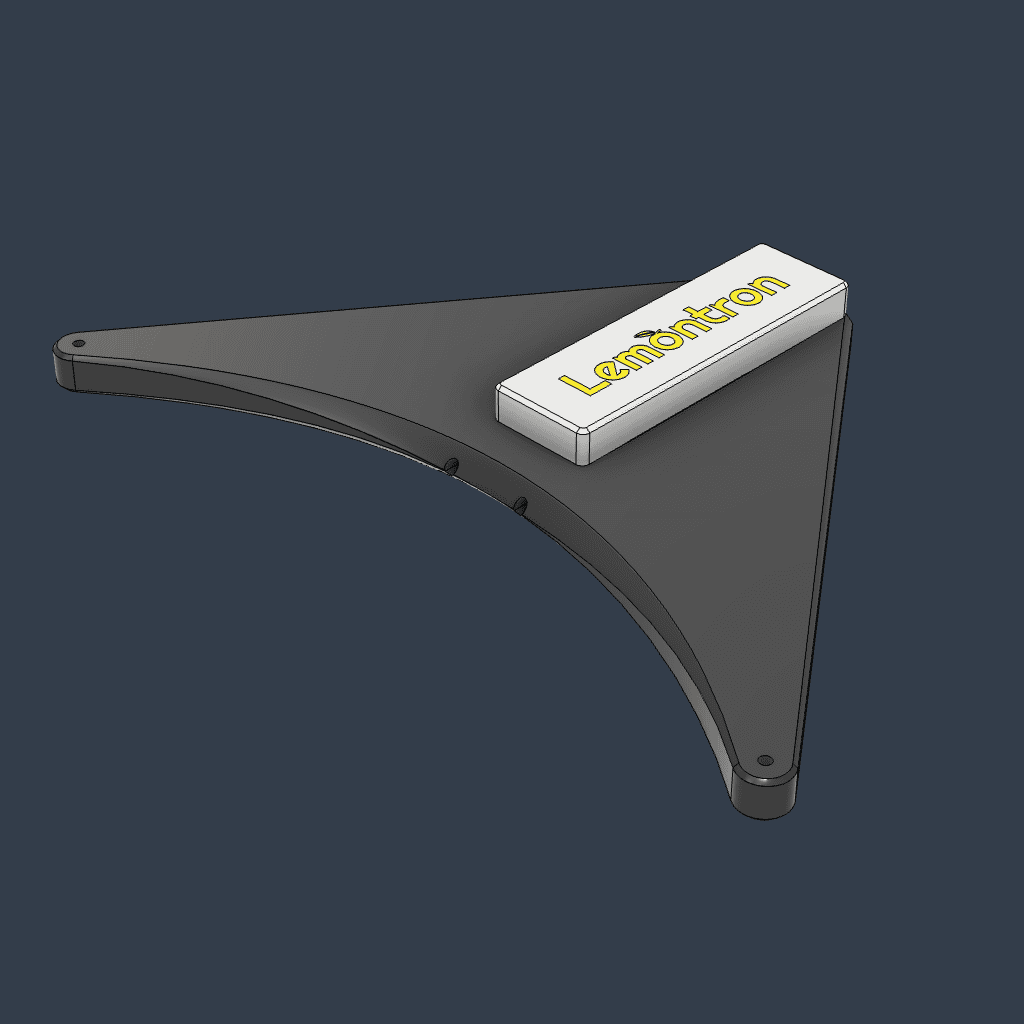

Unibody Chassis

The chassis should be made from a stiff material, and it does not experience savage heat.8 walls, 50% grid -

Mid Plates

High-temp material is required because these serve as the motor mounts.5 walls, 50% grid -

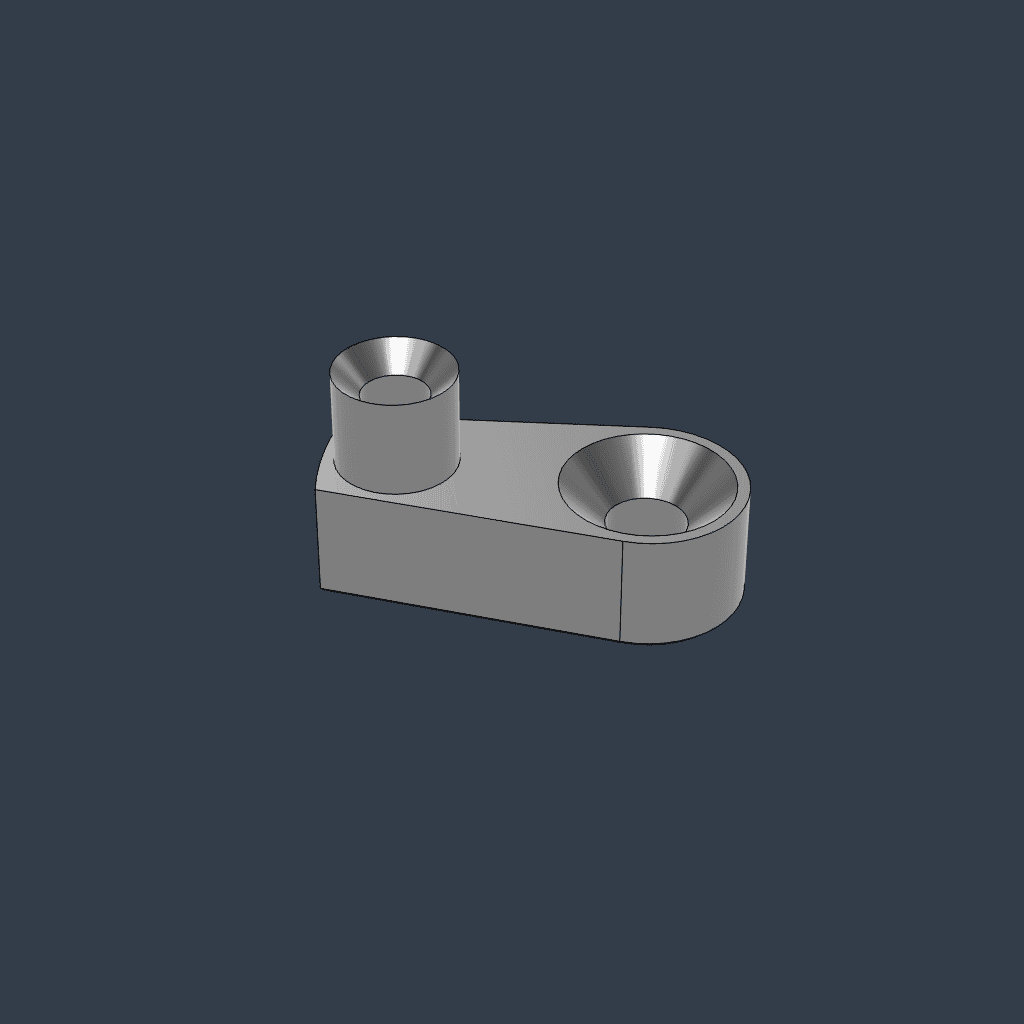

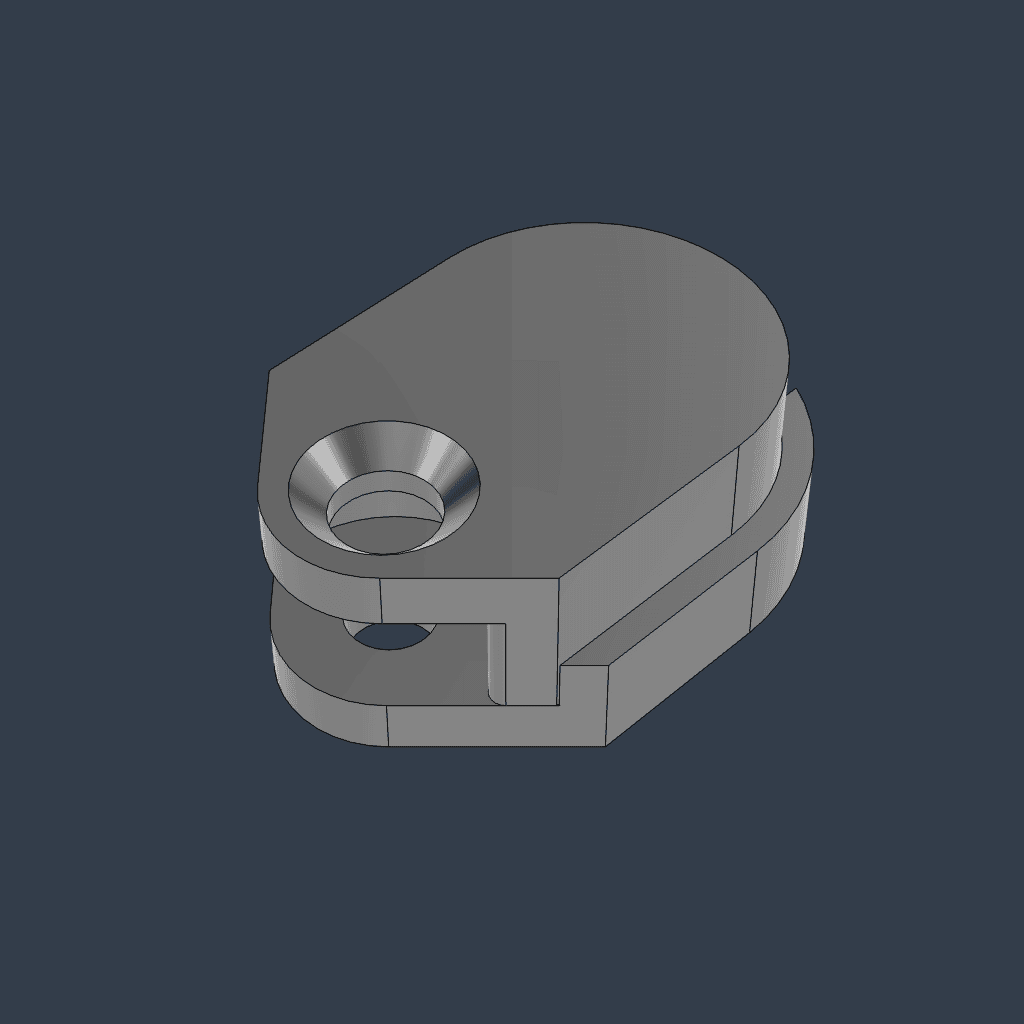

Tensioner

High-temp material is required because this screws directly into the motor.5 walls, 50% grid -

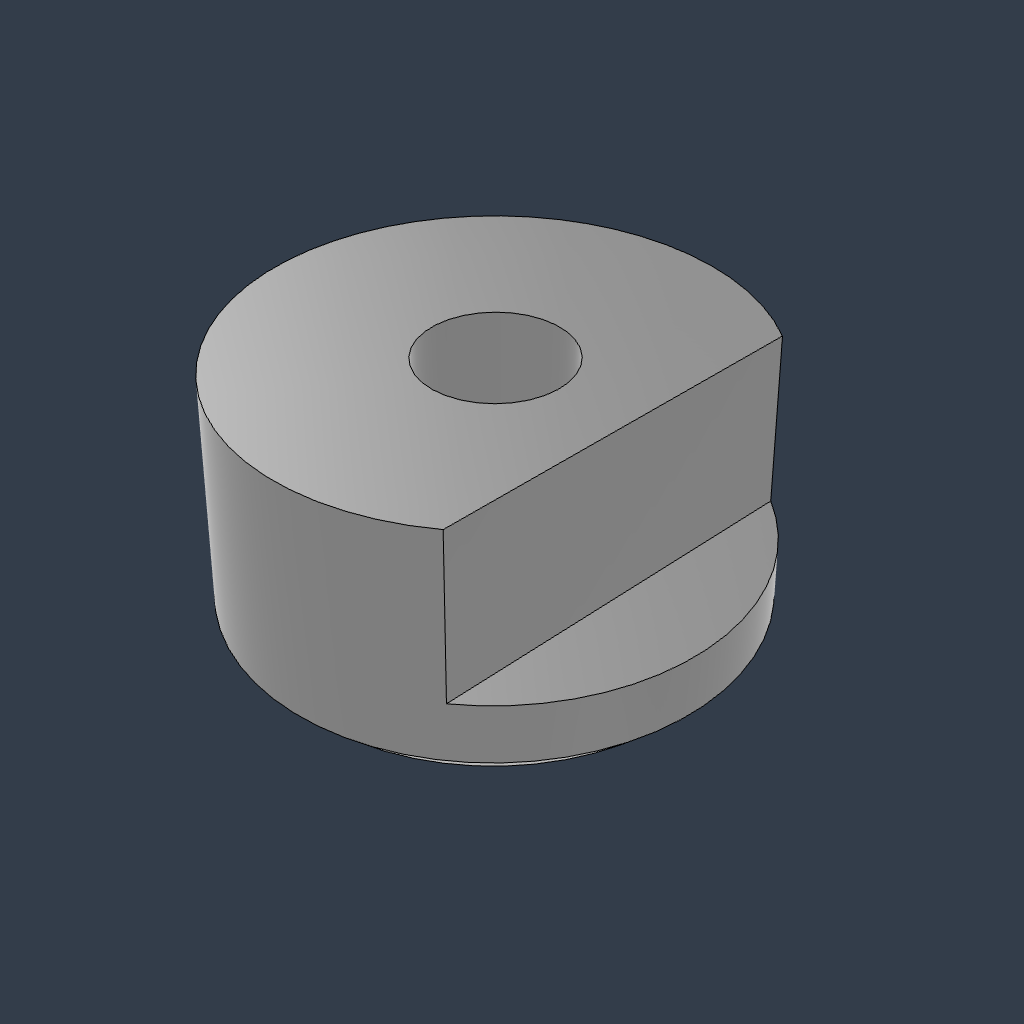

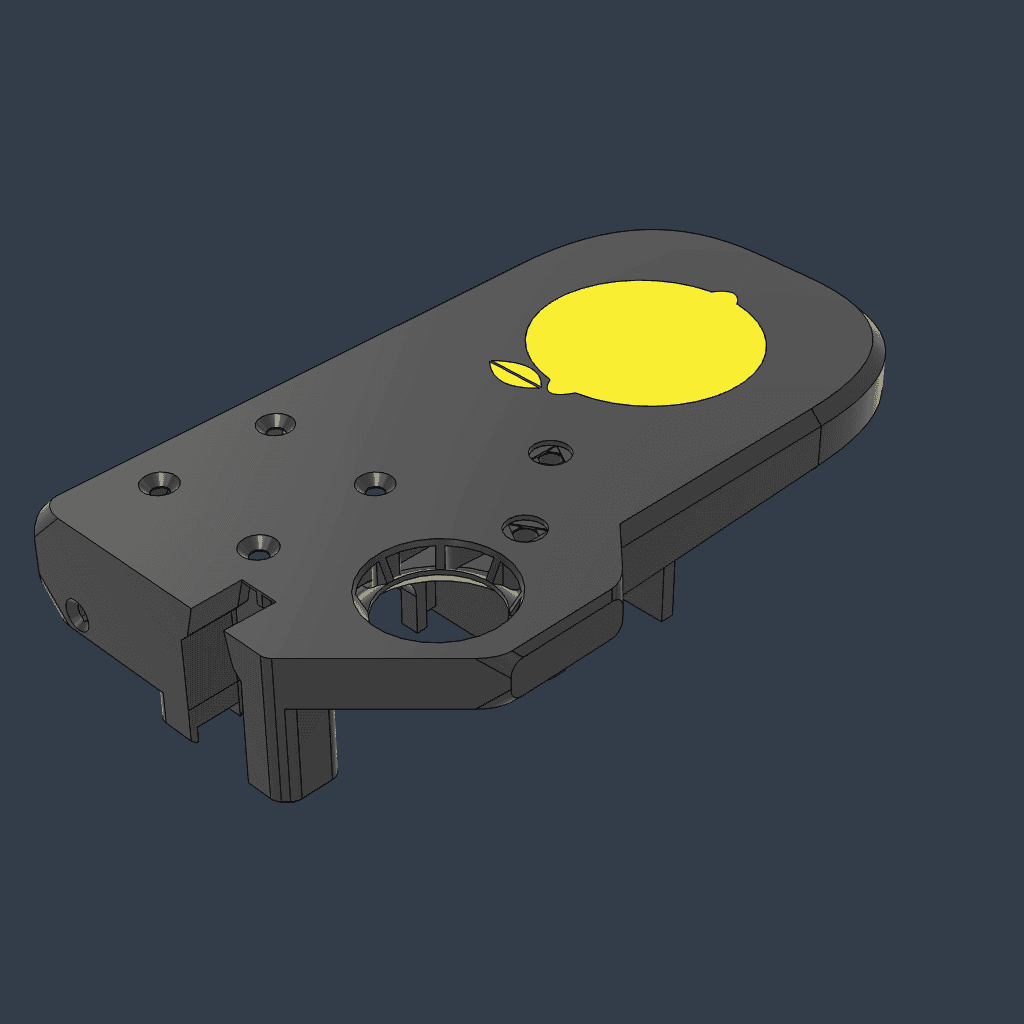

Lemonstruder

Made of two parts. Experiences compression from the spring, so a drift-resistant material with good accuracy is preferred.5 walls, 50% grid -

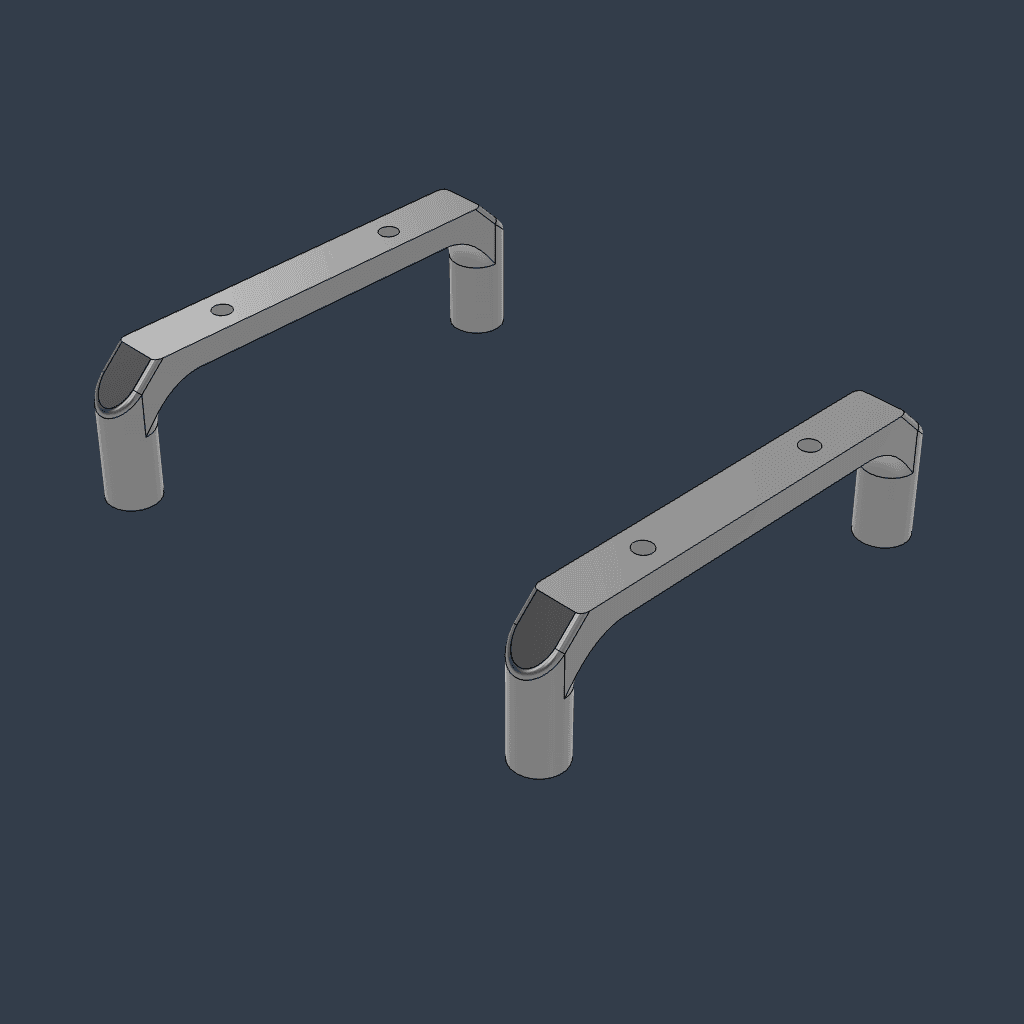

Risers

Raspberry Pi mounts to these, and they keep the SKR Pico pinned down. Material doesn't matter.5 walls, 50% grid -

Z-Tensioner

High-temp material is required because this screws directly into the motor.5 walls, 50% grid -

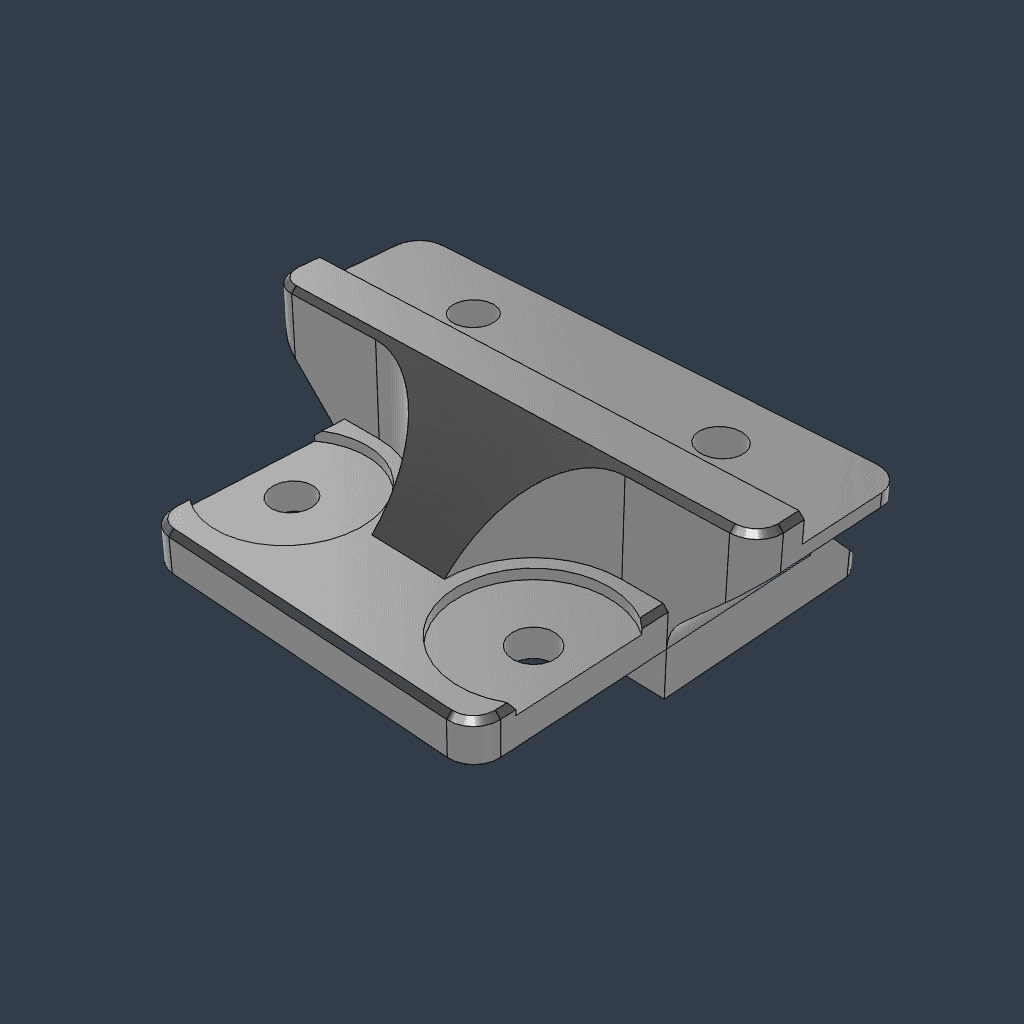

Gantry Block

This links the X and Y rails together to create the XY plane. A stiff material, resistant to warping and drift, is ideal.5 walls, 50% grid, 2mm bottom shell -

Fan Wire Guide

No specific material requirements.3 walls, 25% grid, concentric top -

Filament Guide

No specific material requirements.3 walls, 25% grid

Z-Axis Inventory

-

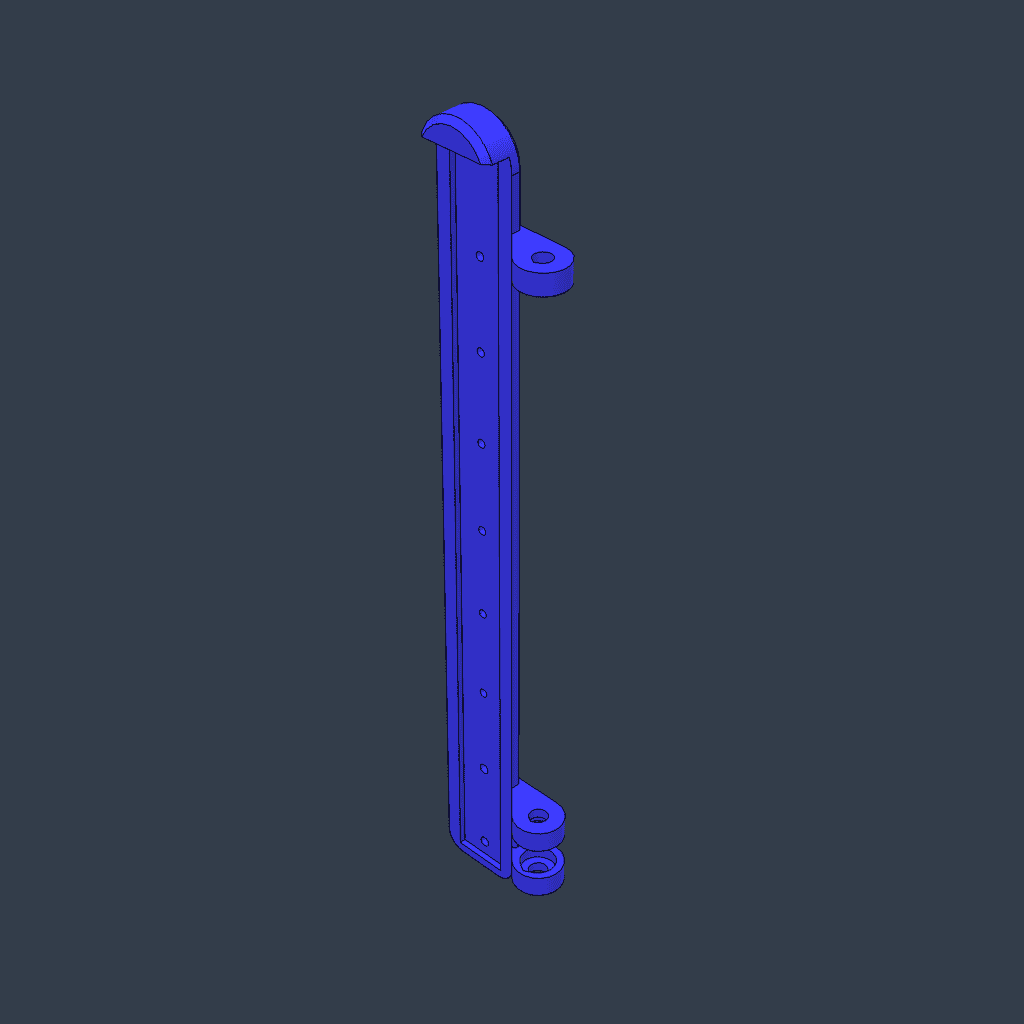

Z-Axis

Choose any material for this part, just make sure it looks awesome.5 walls, 50% grid -

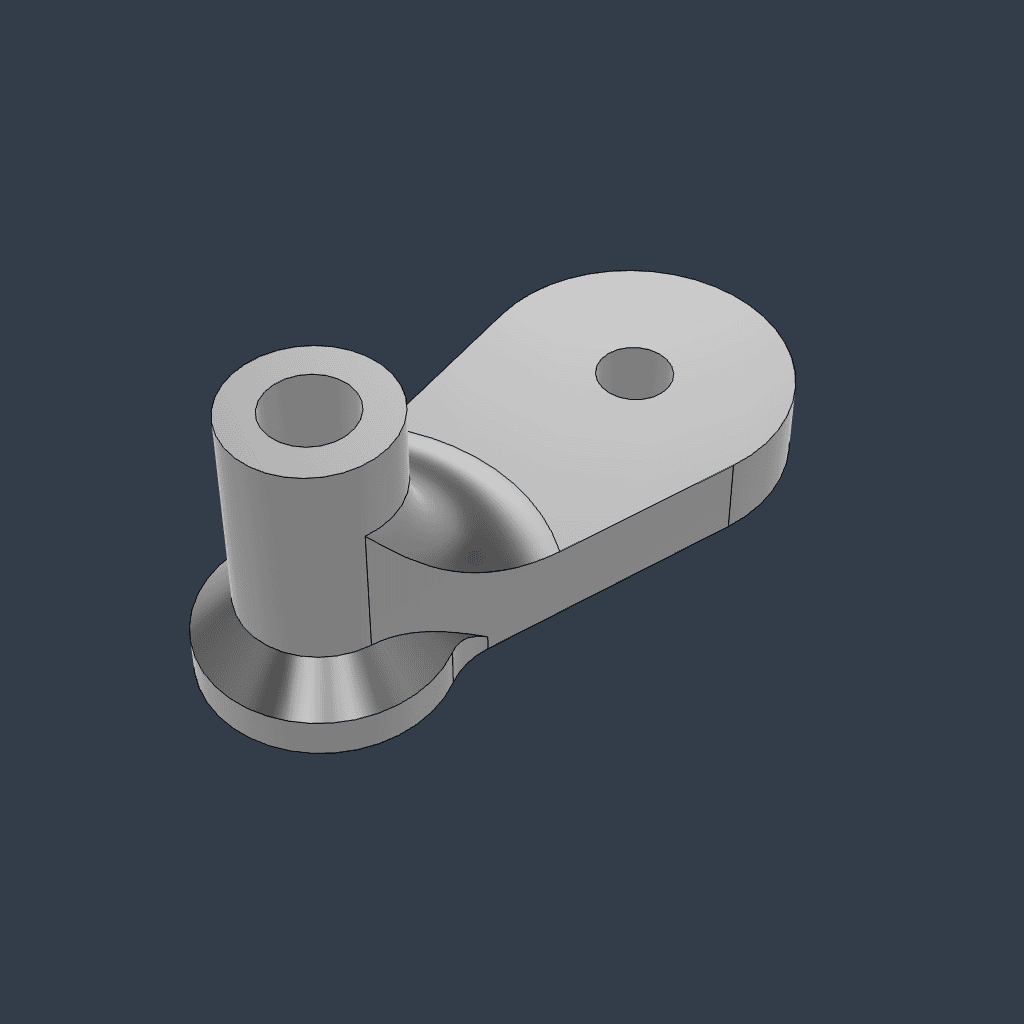

Bed Bracket

The bed bracket is made from two parts. A stiff material like CF-PETG would be ideal.5 walls, 50% grid -

Bed Holder

It's really hard to print, it likes to lift off the bed. Keep an eye on this one. The spine can be printed in whatever you want, I recommend matching the tool head materials.8 walls, 50% grid -

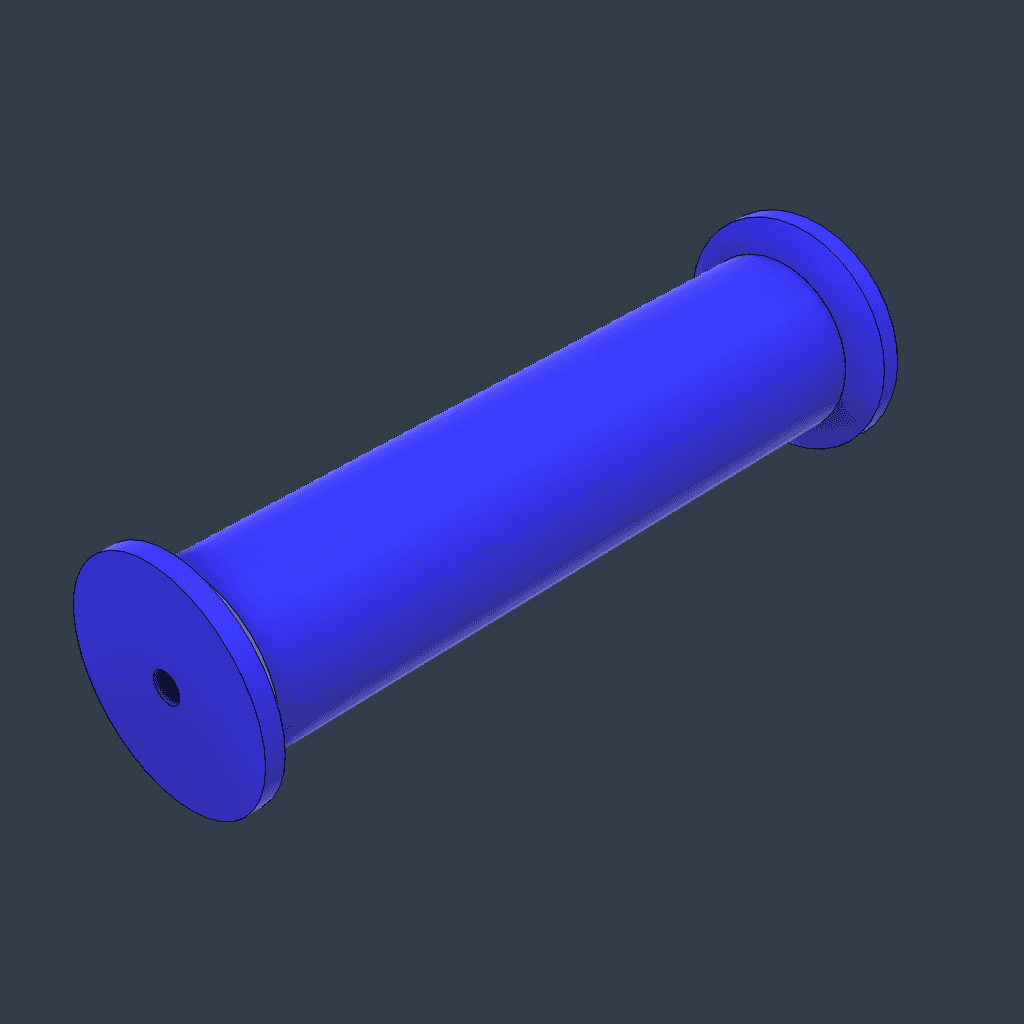

Spool Holder

This has a captive nut, so make sure to add a pause! Layer adhesion is important here, so PLA is a good choice.5 walls, 50% grid, concentric top/bottom -

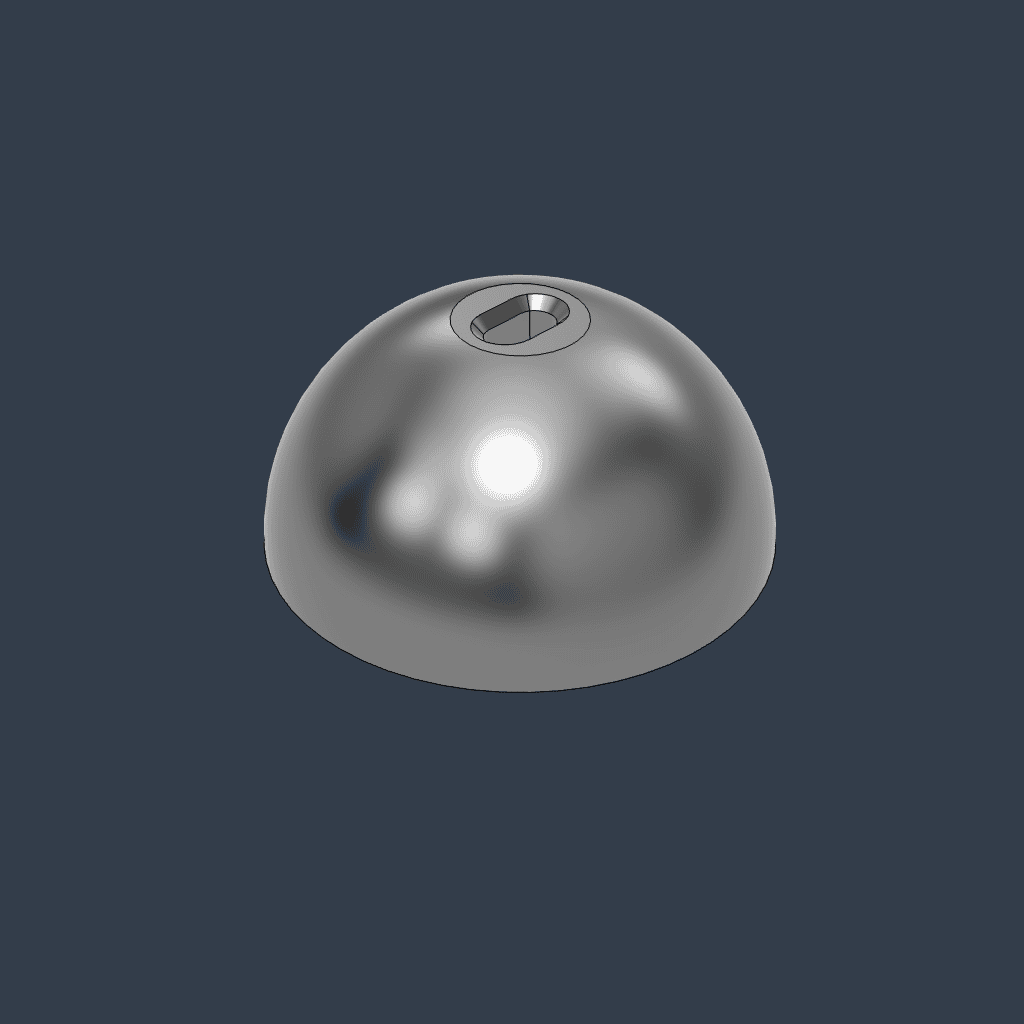

Bed Holder Cups

Holds up the bed! Print two of these.5 walls, 50% grid -

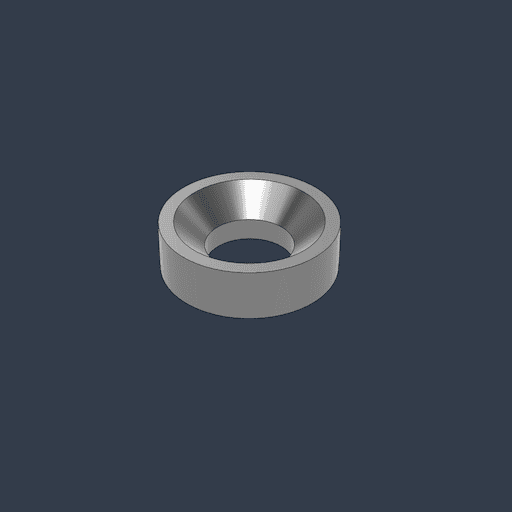

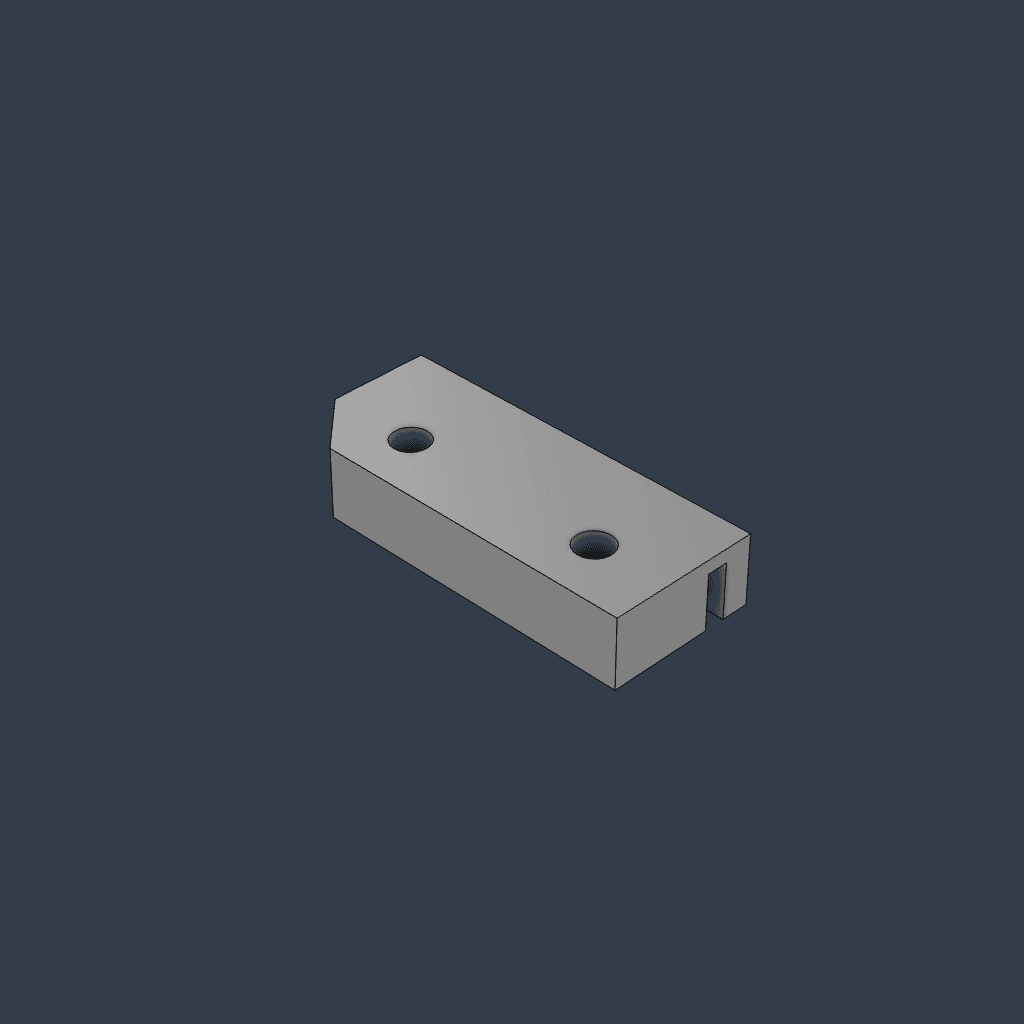

Spacer

Drop these into the Z axis to make the screws line up flush with the back side.

Tool Head Inventory

-

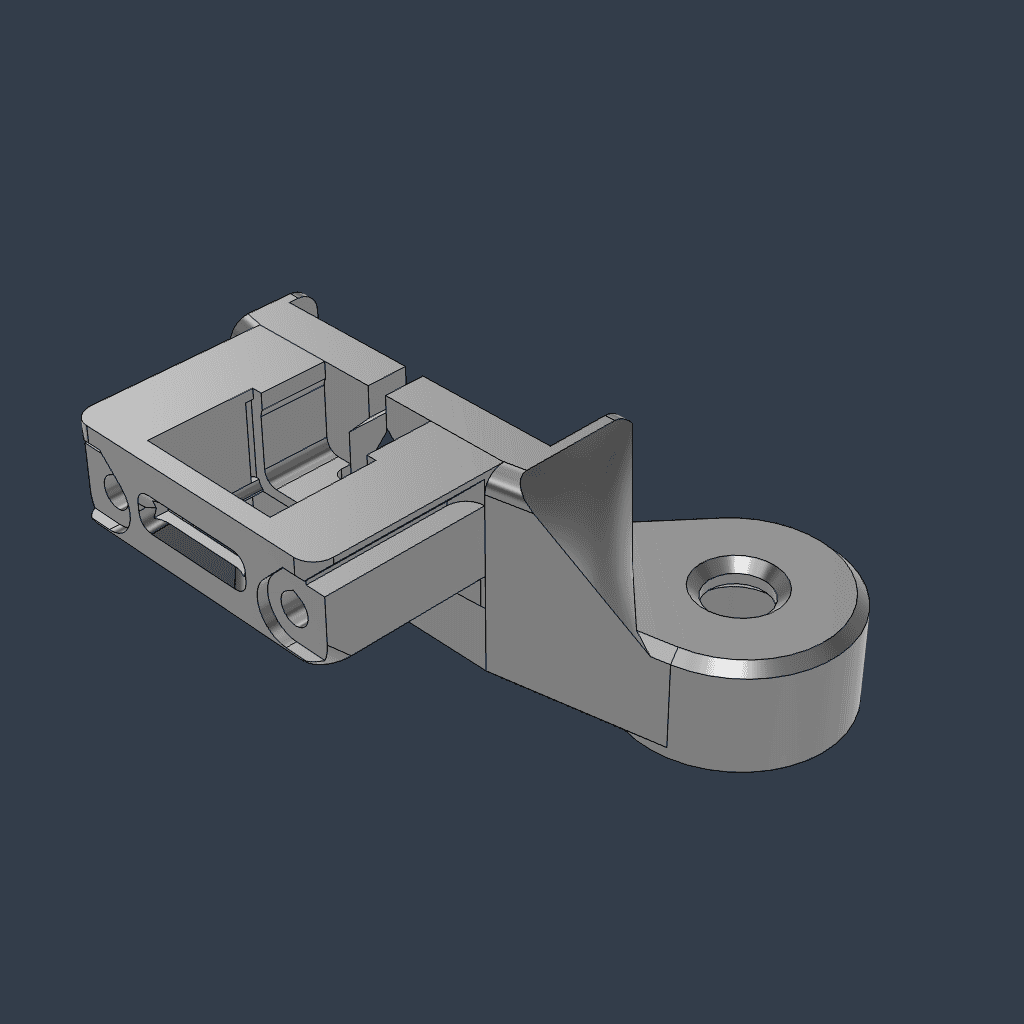

Tool Head

The tool head houses the hotend and thus must be printed in ABS.5 walls, 50% grid, outer/inner wall order -

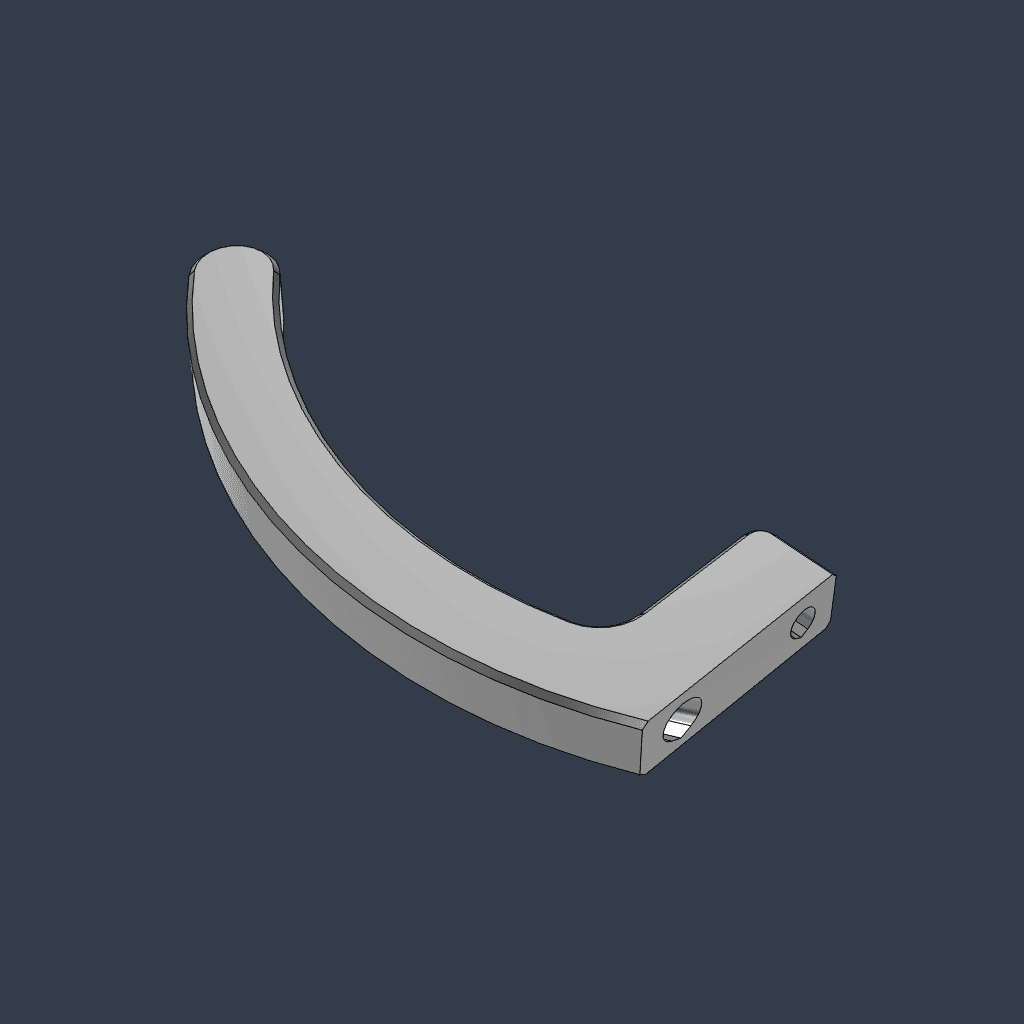

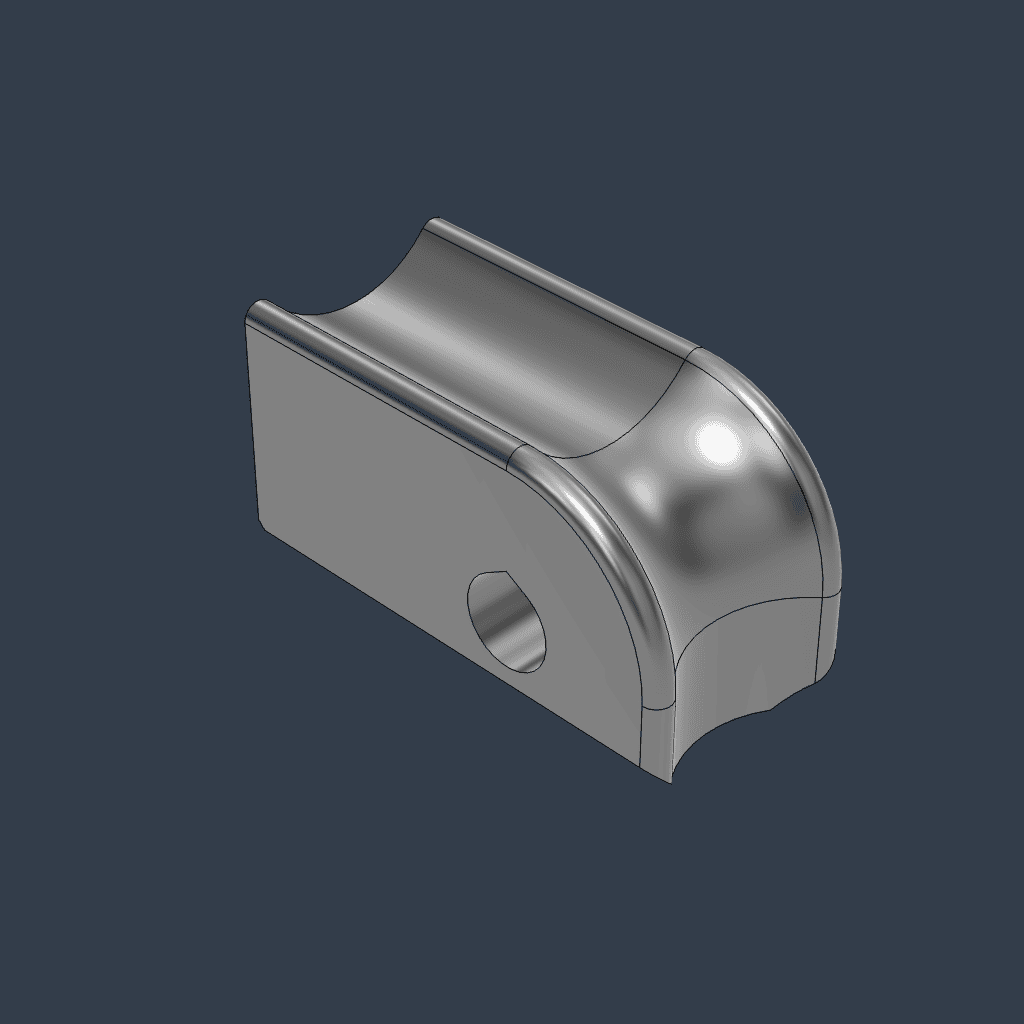

Clip

Clips the belt to the tool end. Layer adhesion matters most, so I recommend PETG or PLA.5 walls, 50% grid -

Clamp

No material requirements. Perhaps use ABS to match.5 walls, 50% grid