Rev E is available to download and make!

However, the build guide doesn't exist! To build Rev E, you have to refer to the Rev A build guide and use

your imagination. Join the Discord!

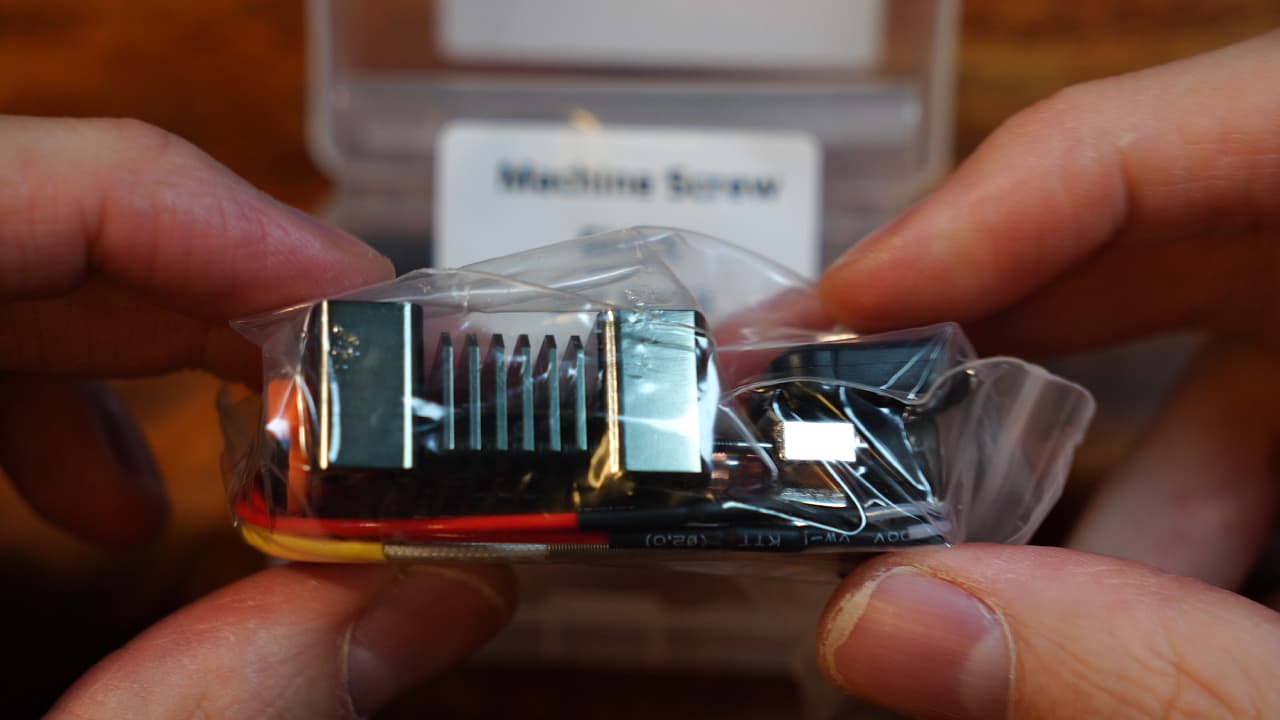

Rev E builds on the previous Lemontrons with the Endgame Lemonstruder, the final complete extrusion system with a 4.5: 1 gear reduction + 100% PTFE filament path, a relocated tensioner unlocking extra rigidity, new quad fans for 8x cooling over Rev A, a wraparound tool head, and hundreds of other tiny tweaks improving fitment, further shaving the BOM, and increased rigidity throughout.